lairdb

Contributor

- Messages

- 872

- Reaction score

- 376

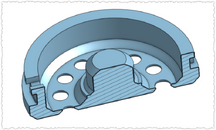

Posted this spool a few weeks ago on Thingiverse and /r/scuba -- didn't even know we had a fabrication forum here until today.

"Not super-amazing, but I'm pleased with the design modularity and printability, and with some of the design choices.

There are quite a few jump spools on Thingiverse, but I didn't love the designs: they required supports, or required load-bearing gluing, or didn't offer good ways to tweak the line capacity, or etc., so: created this from scratch.

I have successfully printed these in PLA, ABS, TPE (NinjaFlex), and TPU. (TPU is actually a pretty good choice, since it will flex rather than crack if it gets smashed between tanks, etc. TPE is a little soft, but also okay.)

Most of the subcomponents use about 5m of material, so if you have samples lying around, this is a handy way to use them."

Thingiverse: Jump Spool / SMB spool (SCUBA) by lairdb

Imgur gallery: Imgur

"Not super-amazing, but I'm pleased with the design modularity and printability, and with some of the design choices.

There are quite a few jump spools on Thingiverse, but I didn't love the designs: they required supports, or required load-bearing gluing, or didn't offer good ways to tweak the line capacity, or etc., so: created this from scratch.

I have successfully printed these in PLA, ABS, TPE (NinjaFlex), and TPU. (TPU is actually a pretty good choice, since it will flex rather than crack if it gets smashed between tanks, etc. TPE is a little soft, but also okay.)

Most of the subcomponents use about 5m of material, so if you have samples lying around, this is a handy way to use them."

Thingiverse: Jump Spool / SMB spool (SCUBA) by lairdb

Imgur gallery: Imgur