That's what TPU is. Maybe you're referring to something else?Perhaps you should try with flex filament.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4S3P Battery Pack

- Thread starter The Chairman

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I guess so. In our country Flex filament is not named as TPU. Flex filament has a shore duro of 95-96. Printed with thick walls has enough rigidity to hold a battery but still can be flexed so as the battery can be inserted and the diameter adapted to it.That's what TPU is. Maybe you're referring to something else?

Makes sense...

- Messages

- 20,805

- Reaction score

- 15,539

- # of dives

- I'm a Fish!

may also want to try ABS if you have an enclosure. Very durable for something like that

Hi,

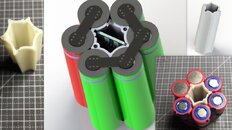

I made a similar holder using ABS purpose of my holder is to keep cells out from each other and help with final assembly. The holder is modular I can stack 2s3p,4s3p, or e.g. 6s3p pack. I use CA glue to fix batteries to the holder. Later I gave up using this because I don’t have my own printer.

Arto

I made a similar holder using ABS purpose of my holder is to keep cells out from each other and help with final assembly. The holder is modular I can stack 2s3p,4s3p, or e.g. 6s3p pack. I use CA glue to fix batteries to the holder. Later I gave up using this because I don’t have my own printer.

Arto

Your batteries are welded together, which becomes problematic going through airports. I would call that a battery pack, and not a holder.Hi,

I made a similar holder using ABS purpose of my holder is to keep cells out from each other and help with final assembly. The holder is modular I can stack 2s3p,4s3p, or e.g. 6s3p pack. I use CA glue to fix batteries to the holder. Later I gave up using this because I don’t have my own printer.

View attachment 724428

Arto

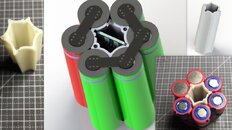

I love this TPU for the clips. I beefed it up a bit and it becomes stiffer with each battery installed. Now to add the electrical connectors. The Orange parts are printed from PAL for rigidity. This is the Gator edition of my battery holder.

Side note, I had to manually chamfer the two bases where the connector slips over them for a nice fit. I went back into Onshape.com and chamfered the drawings so they'll just print that way. I also am having to use a good spray of Aquanet on the bed to keep the prints from releasing too early. A bit of alcohol and the bed wipes clean. The 1.75mm you see in the connector are through the bases as well. They are so you can use a bit of filament to hold things together.

Similar threads

- Replies

- 1

- Views

- 465

- Replies

- 2

- Views

- 244

- Replies

- 4

- Views

- 491

- Replies

- 0

- Views

- 312