I will be documenting this here and on Thingiverse: https://www.thingiverse.com/thing:5386125

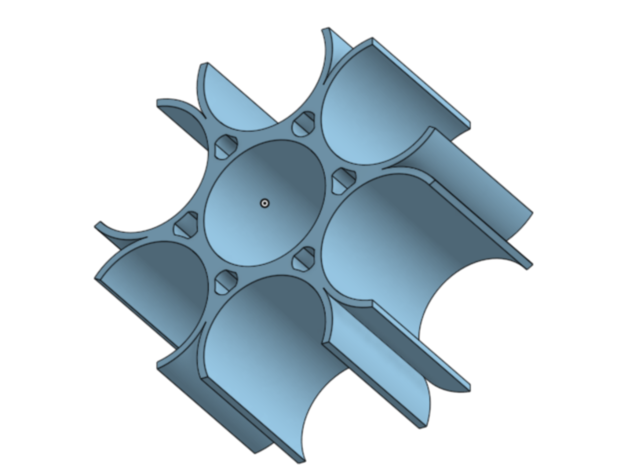

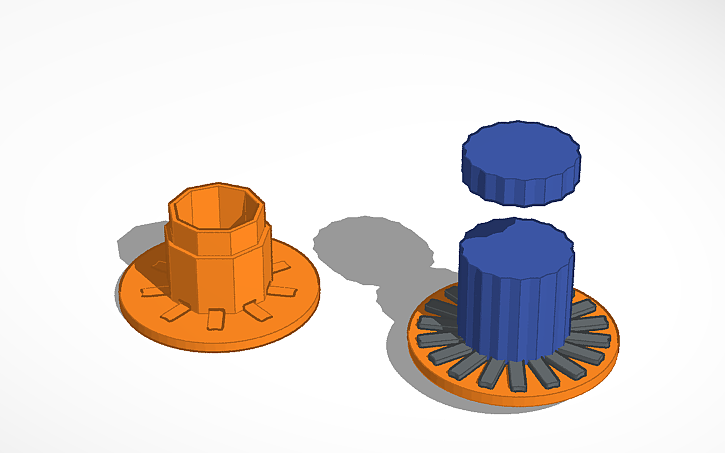

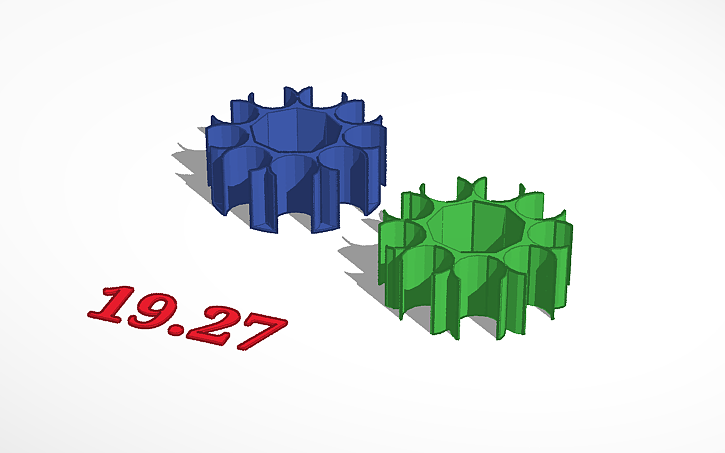

We've all heard it before, you can't fly with that many connected 18650 batteries. That makes a lot of our can lights a no-no, especially on international flights. My first foray into 3D printing was to design a battery pack that any of us can print out that will hold 12 18650 batteries in a 4S3P configuration. For those who don't know the shorthand, that means 3 sets of 4 serial batteries wired in parallel. I started this design in January of 2018 (2019?), but I had no luck or confidence in my printer. She's doing great now since I finished the upgrade I chronicled. There are five printed parts; base upper, base lower, connector, and two Star Wars looking battery clips.

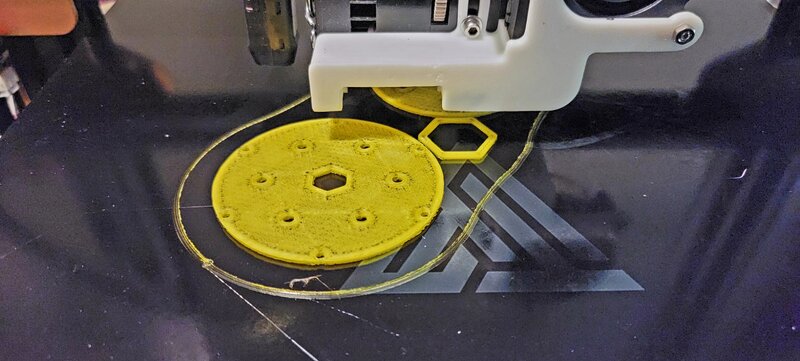

I first printed it in PLA but the clips were too brittle. I've heard a lot of good about PETG, so I'm going to go ahead and print this puppy in that. It's supposed to be stronger, yet springier. I already have limiters and springs somewhere around the shop, and I won't mind designing and printing a PCB if needed. But to get started, I need it in my hand and popping batteries in and out to stress test it. I've got the bases and connectors printing already and they are looking good. In fact, I'm about 2 hours into a ten-hour print.

Please, give me feedback on this, especially as it finishes printing. Share any thoughts, pics or files as you see fit.

We've all heard it before, you can't fly with that many connected 18650 batteries. That makes a lot of our can lights a no-no, especially on international flights. My first foray into 3D printing was to design a battery pack that any of us can print out that will hold 12 18650 batteries in a 4S3P configuration. For those who don't know the shorthand, that means 3 sets of 4 serial batteries wired in parallel. I started this design in January of 2018 (2019?), but I had no luck or confidence in my printer. She's doing great now since I finished the upgrade I chronicled. There are five printed parts; base upper, base lower, connector, and two Star Wars looking battery clips.

I first printed it in PLA but the clips were too brittle. I've heard a lot of good about PETG, so I'm going to go ahead and print this puppy in that. It's supposed to be stronger, yet springier. I already have limiters and springs somewhere around the shop, and I won't mind designing and printing a PCB if needed. But to get started, I need it in my hand and popping batteries in and out to stress test it. I've got the bases and connectors printing already and they are looking good. In fact, I'm about 2 hours into a ten-hour print.

Please, give me feedback on this, especially as it finishes printing. Share any thoughts, pics or files as you see fit.