You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 instructors near miss

- Thread starter abnfrog

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 54,475

- Reaction score

- 8,578

- # of dives

- 500 - 999

I think it's older than that.reg is 5-7 years old

Rusty Shackleford

Contributor

That reg is 20 years old at a minimum.

Gone for diving

Contributor

A bit hard to tell but looks like a tank fell over and hit the bottom of the reg and cracked it open

So since this is the A&I Forum, whose purpose is to discuss things to prevent a future accident, as opposed to flaying the victim, what is the lesson learned going forward? And by the way, having seen more than one bonfire in A&I, my congratulations to @abnfrog for having the courage to post this!

It's easy to go by the book, and say, "The lesson learned is to always read all 45 Service Bulletins before servicing a reg of a type you've serviced a gazillion times before", but we know that just won't happen. In fact, it's silly.

I'll offer this one, but I'm sure there are others.

"Always torque. Always."

But it's more complicated than that. Does the manual say to lube, or leave threads dry?

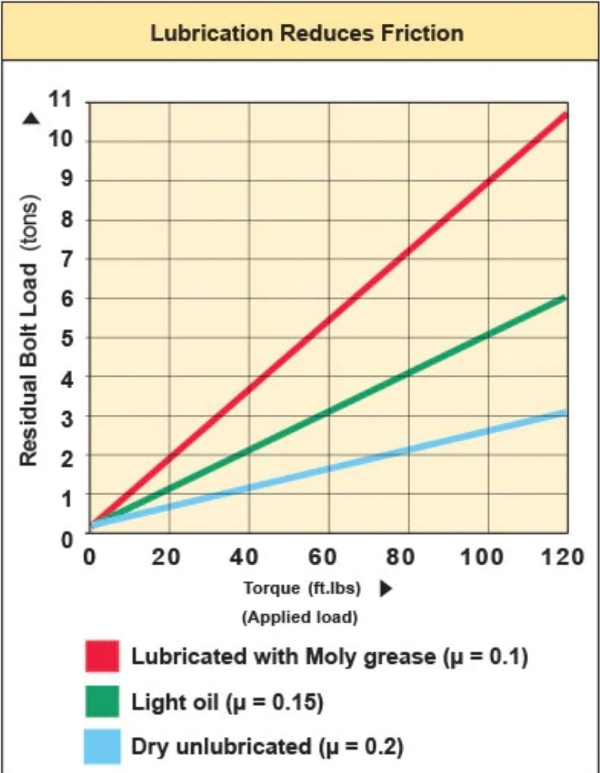

Know that if you choose to throw a little lube on that yoke bolt before honking it down to specification, you've just stressed the reg body with 20-40% more axial load than you thought! So you'll notice I didn't say 'Always torque to spec'. Sometimes, if you're going to deviate from procedure for a reason, you need to make adjustments. But have a reason.

And if you leave them dry (perhaps as specified, or it's not clear in the manual), and then you go 3 years between servicing because the IP is rock solid, you may find that you can't break the verdigris crystals that have formed in the threads exposed to seawater at pressure, and your bolt is frozen.

But guys are always talking about going longer than standard service intervals! What's wrong with that if I check performance regularly? Well for one, your yoke bolt may become frozen.

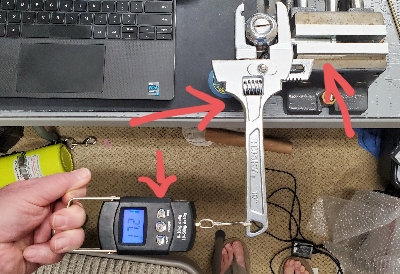

So as always, it's complicated. There are solutions to each of these issues, but they aren't covered in a mfr seminar. Nor in Vance Harlow, for that matter. If you're a DIY'er, you don't need a $200 dial type torque wrench. A $9 Chinese digital luggage scale and an adjustable wrench will work just fine, thank you.

But, "Always torque. Always."

The guy who first taught me years ago didn't bother. He said it was unnecessary.

I think he was wrong.

What else should we have learned?

It's easy to go by the book, and say, "The lesson learned is to always read all 45 Service Bulletins before servicing a reg of a type you've serviced a gazillion times before", but we know that just won't happen. In fact, it's silly.

I'll offer this one, but I'm sure there are others.

"Always torque. Always."

But it's more complicated than that. Does the manual say to lube, or leave threads dry?

Know that if you choose to throw a little lube on that yoke bolt before honking it down to specification, you've just stressed the reg body with 20-40% more axial load than you thought! So you'll notice I didn't say 'Always torque to spec'. Sometimes, if you're going to deviate from procedure for a reason, you need to make adjustments. But have a reason.

And if you leave them dry (perhaps as specified, or it's not clear in the manual), and then you go 3 years between servicing because the IP is rock solid, you may find that you can't break the verdigris crystals that have formed in the threads exposed to seawater at pressure, and your bolt is frozen.

But guys are always talking about going longer than standard service intervals! What's wrong with that if I check performance regularly? Well for one, your yoke bolt may become frozen.

So as always, it's complicated. There are solutions to each of these issues, but they aren't covered in a mfr seminar. Nor in Vance Harlow, for that matter. If you're a DIY'er, you don't need a $200 dial type torque wrench. A $9 Chinese digital luggage scale and an adjustable wrench will work just fine, thank you.

But, "Always torque. Always."

The guy who first taught me years ago didn't bother. He said it was unnecessary.

I think he was wrong.

What else should we have learned?

Just a quick search of eBay, I spot at least 3 MK-20 that are not updated based on the saddle. Others do not have a visible picture of the saddle. There are a few that clearly have the saddle indicating it was updated...

Similar threads

- Replies

- 17

- Views

- 1,091

- Replies

- 102

- Views

- 9,407

- Replies

- 4

- Views

- 418

- Replies

- 0

- Views

- 312

- Replies

- 16

- Views

- 2,833