In the US, but not other places, I think.They have a burst disk that will rupture if the tank is significantly over filled.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Equipment Exploding tank shrapnel injures boy - Ploče beach, Montenegro

- Thread starter DandyDon

- Start date

This Thread Prefix is for incidents caused by equipment failures including personal dive gear, compressors, analyzers, or odd things like a ladder.

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

CT-Rich

Contributor

You learn some thing new every day... They all should have some built in mechanism to prevent catastrophic failure. I understand some countries rely on o-ring failures.Exact in Europe (and most of the world) valves (and tanks) don 't have burst disk

Tanks A Lot

Contributor

I don't have much to add, aside from a few observations and clarifications.

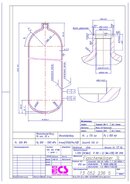

From the video, it appears to be a mix of steel cylinders. Although the footage is fairly grainy, it seems to me that all the remaining cylinders are steel. If I had to hazard a guess, the shape of those cylinders would make me point to ECS or Vítkovice. Both are highly reputable manufacturers that produce excellent cylinders. Given the Eastern European location, Vítkovice would be the more likely source. But again, this is only speculation.

It was stated somewhere that SCUBA cylinders have a wall thickness of around 1/8" (3.2 mm), which is not quite correct. Wall thickness depends on the alloy used, the test pressure, and the outer diameter. Historically, three different formulas have been applied:

Steel SCUBA cylinders generally have a wall thickness between 4.0 mm and 5.0 mm, while very small steel oxygen bottles might be as thin as 2.5 mm. Modern chrome-molybdenum steels have a yield strength of around 755–930 MPa and a tensile strength of 1030–1100 MPa. I would argue that the 1/8" is a tad too low for what is seen in most steel cylinders.

Aluminium fares worse. The modern 6061-T6 alloy has a yield strength of 280–295 MPa and a tensile strength of 330–345 MPa. This lower strength requires a much thicker wall: a typical S80 cylinder will have walls of 12 mm or more.

In general, the larger the diameter and the higher the test pressure, the thicker the wall must be.

Both steel and aluminium cylinders today are designed to burst without fragmentation (clause 10.4.3.3 of ISO 9809 and ISO 7866). They are intended to split along the side wall, with the tear not normally propagating into the base or neck. Mishandling or neglect can, however, still lead to fragmentation, though this is rare with modern alloys.

Burst discs are designed for one specific scenario: over-pressurisation. European countries do not require them on SCUBA cylinders, although some gases are supplied in cylinders with pressure relief devices (PRDs). It is highly unlikely that over-pressurisation was a factor here, as compressors are fitted with reliable safety valves. While these can be tampered with, I doubt that is what happened in this case.

I was also surprised to see some comments suggesting that rapid corrosion can occur within 100 days, even with distilled water. A so-called "100-day rule" was mentioned, which I had never heard of. There is no question that water ingress is harmful to any cylinder, steel or aluminium, but the idea that failure could occur in just 100 days is, in my experience, greatly exaggerated.

Most cylinders that suffer water ingress do so from the compressor itself, which by design, will have water with almost no minerals or salts. While not ideal, I have seen enough wet cylinders from compressors to know that it usually takes far longer than 100 days for corrosion to reach a critical point. In fact, even a couple of years of such "compressor-wetness" may not necessarily cause failure, though obviously this is not something anyone should test deliberately.

The 100-day reference originates from Francis C. Cichy’s report, which specifically examined saltwater ingress. That is a completely different scenario, and extremely rare. I have only personally observed it twice. Saltwater does indeed cause extraordinarily rapid deterioration, much faster than I ever expected. In just a few weeks, it can fuse brass valves to aluminium cylinders, for example. The attached photographs are from one such case.

This is why I find annual visual inspection so valuable in the SCUBA industry. Almost all cylinders will survive a full year of "compressor-wetness”. If inspections are carried out annually, the chance of a dangerous cylinder slipping through is extremely low (excluding gross negligence such as deliberate overfilling). Annual inspection weeds out problem cylinders before they become hazardous.

Without more details, speculation is all we have. Often in such a case, the cause of events is fairly straightforward:

For perspective, an S80 charged to 207 bar will explode with about 0.45 MJ if charged with a diatomic gas such as air. That is roughly equivalent to 100 grams of TNT. A US-made Mk II hand grenade in World War II carried 52 grams of TNT, which means the energy released by a bursting S80 is comparable to two of those grenades detonating. I'm not an expert by any means on explosions, but the math does not leave me surprised of such an outcome. Quite the contrary, I would have expected even more bodily harm to more bystanders.

Either way, it serves as another reminder of the importance of adhering to annual inspection schedules.

From the video, it appears to be a mix of steel cylinders. Although the footage is fairly grainy, it seems to me that all the remaining cylinders are steel. If I had to hazard a guess, the shape of those cylinders would make me point to ECS or Vítkovice. Both are highly reputable manufacturers that produce excellent cylinders. Given the Eastern European location, Vítkovice would be the more likely source. But again, this is only speculation.

It was stated somewhere that SCUBA cylinders have a wall thickness of around 1/8" (3.2 mm), which is not quite correct. Wall thickness depends on the alloy used, the test pressure, and the outer diameter. Historically, three different formulas have been applied:

- Bach-Clavarino formula (US): Often predicts failures at higher pressures than seen in practice.

- Mean Diameter Formula (EU): Can be unsafe for thin walls and overly conservative for thick walls.

- Lamé von Mises formula: Currently regarded as the most accurate.

Steel SCUBA cylinders generally have a wall thickness between 4.0 mm and 5.0 mm, while very small steel oxygen bottles might be as thin as 2.5 mm. Modern chrome-molybdenum steels have a yield strength of around 755–930 MPa and a tensile strength of 1030–1100 MPa. I would argue that the 1/8" is a tad too low for what is seen in most steel cylinders.

Aluminium fares worse. The modern 6061-T6 alloy has a yield strength of 280–295 MPa and a tensile strength of 330–345 MPa. This lower strength requires a much thicker wall: a typical S80 cylinder will have walls of 12 mm or more.

In general, the larger the diameter and the higher the test pressure, the thicker the wall must be.

Both steel and aluminium cylinders today are designed to burst without fragmentation (clause 10.4.3.3 of ISO 9809 and ISO 7866). They are intended to split along the side wall, with the tear not normally propagating into the base or neck. Mishandling or neglect can, however, still lead to fragmentation, though this is rare with modern alloys.

Burst discs are designed for one specific scenario: over-pressurisation. European countries do not require them on SCUBA cylinders, although some gases are supplied in cylinders with pressure relief devices (PRDs). It is highly unlikely that over-pressurisation was a factor here, as compressors are fitted with reliable safety valves. While these can be tampered with, I doubt that is what happened in this case.

I was also surprised to see some comments suggesting that rapid corrosion can occur within 100 days, even with distilled water. A so-called "100-day rule" was mentioned, which I had never heard of. There is no question that water ingress is harmful to any cylinder, steel or aluminium, but the idea that failure could occur in just 100 days is, in my experience, greatly exaggerated.

Most cylinders that suffer water ingress do so from the compressor itself, which by design, will have water with almost no minerals or salts. While not ideal, I have seen enough wet cylinders from compressors to know that it usually takes far longer than 100 days for corrosion to reach a critical point. In fact, even a couple of years of such "compressor-wetness" may not necessarily cause failure, though obviously this is not something anyone should test deliberately.

The 100-day reference originates from Francis C. Cichy’s report, which specifically examined saltwater ingress. That is a completely different scenario, and extremely rare. I have only personally observed it twice. Saltwater does indeed cause extraordinarily rapid deterioration, much faster than I ever expected. In just a few weeks, it can fuse brass valves to aluminium cylinders, for example. The attached photographs are from one such case.

This is why I find annual visual inspection so valuable in the SCUBA industry. Almost all cylinders will survive a full year of "compressor-wetness”. If inspections are carried out annually, the chance of a dangerous cylinder slipping through is extremely low (excluding gross negligence such as deliberate overfilling). Annual inspection weeds out problem cylinders before they become hazardous.

Without more details, speculation is all we have. Often in such a case, the cause of events is fairly straightforward:

- The compressor was poorly maintained and delivered partially wet air (a common issue). Cost-cutting may have been at play.

- Visual inspections were skipped for an extended period. Again, cost-cutting could be a likely issue.

- A cylinder deteriorated to the point of bursting during filling. No over-pressurisation necessary.

For perspective, an S80 charged to 207 bar will explode with about 0.45 MJ if charged with a diatomic gas such as air. That is roughly equivalent to 100 grams of TNT. A US-made Mk II hand grenade in World War II carried 52 grams of TNT, which means the energy released by a bursting S80 is comparable to two of those grenades detonating. I'm not an expert by any means on explosions, but the math does not leave me surprised of such an outcome. Quite the contrary, I would have expected even more bodily harm to more bystanders.

Either way, it serves as another reminder of the importance of adhering to annual inspection schedules.

I should add that the excellent ASME requirements allow us as pressure vessel design engineers to use a much wider range of available steel materials but in addition they require a four times the allowable working pressure to burst. Similar our old trusted British Standards were also very similar.

While the EU European committee standards of vested interested parties allow a much narrow smaller range of steel materials but incorporate a much greater tensile strength while at the same time allow only a three times working pressure to burst. Its good for sales light weight and cheap to manufacture

The kicker here is that steel doesn't give a hoot about tensile strength and loves to convert itself from a high tensile strength into a thin wall rusty thin skin at the drop of a level of water vapour over -40 dew point so rust is created so quickly even a 2 minute hydro at you local dive shop creates a corrosion event.

Add to the mix your local scuba clown a lack of investment and a level of ignorance coupled with self packing any old junk zeolite off of EBay and China you have no idea how effective these chemical are and you have the recipe for these catastrophic events.

It's the June July August event. Cylinder new in June dive off your old junk Coltri compressor self pack with chemical you buy off a risky dink dive shop or EBay from China and the 100 days later time bomb comes up and bites you in the backside. Or in the case of this child he gets to loose his hand for someone's utter stupidity carelessness and utter contempt. Just saying.

All this assuming salt water, I supposeNot quite true Im afraid. You need to consider that cylinders or pressure vessels I should say are designed by engineers new. A combination of material tensile strength over diameter with pressure and wall thickness to tensile strength dictates weight.

Now a static pressure vessel using a high tensile steel with a wall thickness of 7.5mm would be capable of a working pressure of 350 bar (5000psi) over a 250mm diameter

However under your ASME VIII div 1 appendix 22 would require a wall thickness of 19mm (3/4")

Both as safe as each other with one using a much higher tensile steel material.

But non of these calculations are effective when the cylinder is heavily corroded with internal rust

It's known as the 100 day rule where a perfectly new steel cylinder will over 100 days with a few cc's of water internally will corroded sufficient for the shell to fragment.

The no burst option in the original design has in effect been eroded away.

If I had to hazard a guess, the shape of those cylinders would make me point to ECS or Vítkovice. Both are highly reputable manufacturers that produce excellent cylinders.

For brevity lets take your first suggestion as the example to discuss.

And use the ECS (Euro Cylinder Systems) cylinders as the example

Now as for reputable and producing excellent cylinders on the contrary they produce crap of a quality on par with the junk from China but for the unsuspecting and ignorant scuba market. Brand oriented with only catalogue knowledge. No matter stick a pinky dink decal on it and away you go .

It was stated somewhere that SCUBA cylinders have a wall thickness of around 1/8" (3.2 mm), which is not quite correct.

That would be my suggestion of 1/8" (3.2mm) wall thickness as a nearest imperial equivalent measurement this was for the benefit of our fellow American divers to better understand the specific European stupidity within the scuba industry. Enforcing inferior CE standards with poor manufacturing.

So lets use your suggestion to begin and using your example of ECS cylinders and 1/8" wall thickness with an explosion while new when filling. The following:

Below is an example of a ECS cylinder with a slightly higher working pressure of 232 bar (3364 psi)

than the American more common 207 Bar (3000 psi) norm.

It was sold brand new by a large dive shop with its own inland fresh water lake in the UK and exploded in the same dive shop some 6 months later while being filled to 232 bar although it never reached full pressure.

Although the explosion didn't kill anyone or amputate the hand of any 14 year old located 50 meters away but non the less the wall thickness when new according to the drawing was 3.3mm of bright shiny metal. Both Jpeg and Pdf enclosed below

For reference the drawing of these type cylinders I enclose below in PDF

Attachments

Really? Not so. Look carefully at the drawing above of the exploding ECS cylinder 6 months old in a fresh water lake while being filled. It clearly states ISO 9809 now subsequently the proverbial Bull dung hit the fan and our beloved scuba la la land gurus and yen masters went into overdrive cover up mode. More on that later.Both steel and aluminium cylinders today are designed to burst without fragmentation (clause 10.4.3.3 of ISO 9809 and ISO 7866). They are intended to split along the side wall, with the tear not normally propagating into the base or neck. Mishandling or neglect can, however, still lead to fragmentation, though this is rare with modern alloys.

Next our beloved Health and Safety Executive churns out what can only be described as their version of a hapless rebuttal with the following.

www.hse.gov.uk

www.hse.gov.uk

A wonderful piece of the hopeless guidance from the hapless to the helpless

Note the cylinder in question on the front page and described in the article.

I especially like the detail "

"Research has shown that corrosion rates in cylinders containing compressed air or nitrox can be more than 100 times faster than normal. If fresh water is present in the cylinder this can mean the loss of more than 2 mm of the thickness of the cylinder wall within 6 months. This is increased to more than 5 mm in the presence of salt water. Diving cylinder walls are generally between 2 and 5 mm thick". (end quote)

You see where Im going with this. On a purely cynical frame of mind you understand. Save to avoid confusion lest I bring up those cigarettes later.

Diving cylinders – the danger of internal corrosion - HSE

The use of volunteers in diving at work projects

A wonderful piece of the hopeless guidance from the hapless to the helpless

Note the cylinder in question on the front page and described in the article.

I especially like the detail "

"Research has shown that corrosion rates in cylinders containing compressed air or nitrox can be more than 100 times faster than normal. If fresh water is present in the cylinder this can mean the loss of more than 2 mm of the thickness of the cylinder wall within 6 months. This is increased to more than 5 mm in the presence of salt water. Diving cylinder walls are generally between 2 and 5 mm thick". (end quote)

You see where Im going with this. On a purely cynical frame of mind you understand. Save to avoid confusion lest I bring up those cigarettes later.

Heck when did I say that? LOL Assume nothing verify everything with reference. The answer may come later if we are allowed to continue or if I don't die of boredom but it is not quite what you're expecting.All this assuming salt water, I suppose

They all should have some built in mechanism to prevent catastrophic failure. I understand some countries rely on o-ring failures.

That's a hard thing to design and produce with any degree of a tight range of reliability and repeatability.

One of the best examples in the sports scuba industry was with US Divers and the Conshelf, Deepstar, and Calypso range of regulators using the A clamp method of connecting first stage to cylinder. This worked on a clamp manufactured as a hot brass stamping I think from memory it was Cz120 brass.

As you would expect as the required working pressure of cylinders increased US Divers under John Cronin agreed with engineering that the wall thickness of the clamp be increased however what is not well known is that the elongation and deflection of the clamp under load was calculated to extrude the O-Ring above the working pressure but under the burst pressure. This control was using a specific polymer material from Du Pont and not the general purpose junk 0-Ring "R" Us from China you get in todays scuba 0-Rings from the cheapest hydraulic supply shop vendors as you find now. Oh and EBay I guess.

The clamp deflected even under the working pressure load but over a certain pressure the ring popped out. Change the ring material or use the same material but say with a 90 shore hardness and the ring stayed in solid.

By contrast with cylinders design this was achieved in using either a countersunk O-ring chamfer in the cylinder neck or by using a counterbore with a shallow 5 degree approach angle for clearance.

One reason why a properly engineered design pressure products for an underwater pressure application would never use the Hydraulic O-ring groove and tolerance calculations you find in the "off the shelf" Hydraulic Guides. A sort of men from the boys and clowns distinction I guess.

TrimixToo

Contributor

You learn some thing new every day... They all should have some built in mechanism to prevent catastrophic failure. I understand some countries rely on o-ring failures.

Burst discs don't always do what you might expect.

Attachments

Similar threads

- Replies

- 0

- Views

- 642

- Replies

- 4

- Views

- 1,678

- Replies

- 0

- Views

- 1,437

- Replies

- 1

- Views

- 823

- Replies

- 1

- Views

- 1,139