The closest I've ever come to a serious incident was precipitated when a finger-tight 2nd stage fell off during a sidemount cave dive. My second stages now are tight; maybe 30-35 inch-pounds (about 2.5-3 ft-pounds, or 3.5-4 newton-meters).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

To be, finger tight or wrench tight is the question ?

- Thread starter Nemrod

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Torque is specified by some mfrs.Maybe @rsingler knows if a torque is specified by manufacturers?

The most common torque is 25-40 in-lb.

This one from an old Aqualung Legend manual.

That said, I rarely do that much. Finger tight was okay for me until one trip where my long hose oring extruded because the nut had spun so far off. A quick hose fold and re-tighten took care of it, but since then I've used a wrench for just past finger-tight.

There is one exception, IMO. I honk down the Atomic Aquatics Comfort Hose. That seal uses an oring that is captured at the very edge of the fitting. ANY loosening and you may have catastrophic gas loss. A real design flaw, IMO.

The XS Scuba knockoff doesn't have that flaw. It's designed like a standard hose, with an oring around the inner shaft of the fitting, so it will be multiple turns before it starts to leak.

But then, that shaft is plastic, so there's that weakness. And the other end has two parts with yet another oring that can leak. Always compromises.

Perhaps a little more explanation is in order for readers who don't quite understand what we are talking about. Here is an image of the hose to 2nd stage regulator connection copied from O-rings for Divers. The nut in question is the one on the left which is tightened against the fitting on the right

Hose connector to the second stage regulator is a dynamic seal. Look closely and you can see the brown O-ring in the groove under the lock nut.

The force acting to blow the hose off the fitting is only about 5 Lbs or 2¼ Kg so the strength of the nut is not a concern. The nut doesn't even have to be butted up against the fitting to avoid leakage because it is a dynamic seal. The only concern is unscrewing enough that the threads and O-ring are no longer engaged, which would blow the hose off making the regulator unusable and relatively rapidly drain your tank.

If you use a wrench, which manufacturers recommend, good practice requires using a backup wrench — one on the nut and the other on the fitting installed in the plastic second stage housing. Many second stage regulators don't have enough width for a standard open-end or small adjustable wrench to fit so a "thin" wrench may be required:

For this application, an inexpensive stamped metal thin wrench is more than adequate because the torgue is so low.

Hose connector to the second stage regulator is a dynamic seal. Look closely and you can see the brown O-ring in the groove under the lock nut.

The force acting to blow the hose off the fitting is only about 5 Lbs or 2¼ Kg so the strength of the nut is not a concern. The nut doesn't even have to be butted up against the fitting to avoid leakage because it is a dynamic seal. The only concern is unscrewing enough that the threads and O-ring are no longer engaged, which would blow the hose off making the regulator unusable and relatively rapidly drain your tank.

If you use a wrench, which manufacturers recommend, good practice requires using a backup wrench — one on the nut and the other on the fitting installed in the plastic second stage housing. Many second stage regulators don't have enough width for a standard open-end or small adjustable wrench to fit so a "thin" wrench may be required:

For this application, an inexpensive stamped metal thin wrench is more than adequate because the torgue is so low.

These connections from LP hose to second stage are hermaphrodites, in that they have both male and female components  .

.

Since the O-ring of the hose slides into the barrel of the second stage, as Akimbo eloquently explains, just being a little loose does not cause an immediate leak. It must unscrew completely. This is unlike hose connections to the first stage where an extruded O-ring is immediately possible if the hose fitting backs off a little bit, it does not take much especially on the HP fittings.

James

Since the O-ring of the hose slides into the barrel of the second stage, as Akimbo eloquently explains, just being a little loose does not cause an immediate leak. It must unscrew completely. This is unlike hose connections to the first stage where an extruded O-ring is immediately possible if the hose fitting backs off a little bit, it does not take much especially on the HP fittings.

James

This is unlike hose connections to the first stage where an extruded O-ring is immediately possible if the hose fitting backs off a little bit, it does not take much especially on the HP fittings.

Good point. IMO, hand tightening any SAE J1926 straight thread boss connection (used on Scuba regulators) introduces unnecessary risk of failure.

For other readers:

An HP O-ring failure is a very minor problem in terms of rapidly draining your tank, but it will prematurely abort your dive. This is due to the very small restrictor holes in the 1st stage's HP port and in virtually all HP hoses. It is for sensing pressure, not flow.

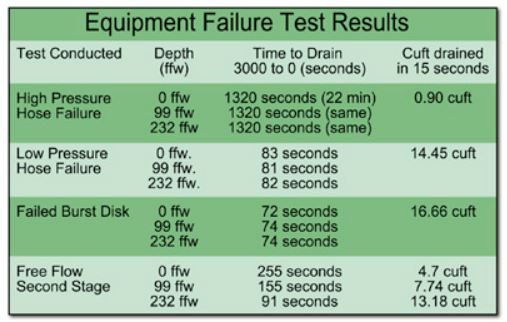

(Table Reprinted by permission)

This table appeared in Life Ending Seconds, 3000 to Zero in 72 Seconds, Advanced Diver Magazine by Curt Bowen

Even though the IP (Intermediate Pressure) is lower at 135 PSI/9.3 Bar, the flow rate is a far higher. As a result, an open LP hose can drain a typical single tank in a bit over a minute. Note that a free-flowing second stage is significantly slower.

This brings up an interesting question: Does a typical diaphragm or piston first stage have a sufficient Cv (flow coefficient) to support an open LP hose and still have enough backpressure for an Octopus to function? I "suspect" not, but I have no idea what their Cv's are nor have I tested them.

This argues in favor of a redundant gas supply (second tank and regulator), staying very close to a buddy, or never diving deeper than you can safely make a free ascent.

I was not trying to define right or wrong or better or worse, I was asking for what other divers do. I answered your question in my initial post #1. I was also referring to the LP hose to the second stages but we have also been discussing the HP and LP to the first stage, which is slightly off topic.Is there any advantage to be finger tight rather than lightly wrench tight?

James

I saw you mentioned that someone could switch a reg underwater: I didn’t know it was a thing.I was not trying to define right or wrong or better or worse, I was asking for what other divers do. I answered your question in my initial post #1. I was also referring to the LP hose to the second stages but we have also been discussing the HP and LP to the first stage, which is slightly off topic.

James

I was genuinely asking: I think nowadays nobody would switch a reg underwater, so I’d have assumed that the better practice would be to slightly tighten more?

Myself, I first use my fingers then I use a slight wrench tightening to finish, but I am quite new to this. That’s why I am asking