Zung

Contributor

This thread is to give some data points on the effect of long term storage.

History: I bought this MK20 new from an LDS in June 2000, went on a dive trip, and then stored it in a clean, dry closet while I watched the kids grow. In August 2009, the kids got certified, I pulled it out, did a quick test, everything OK, and went on diving my merry way.

The G250 I’m not so sure; I have neither recollection nor paperwork that says when and where I got it. I found out later on it’s much older than the first stage.

Anyway, the last time I tested this rig was in January 2010: the IP was 9 bar / 131 PSI, no creep, and the recovery was instantaneous; the cracking effort was 24 mm / .94 inch of water. I thought about servicing it, but couldn’t find any good reasons for it, so I went on diving some more.

February 2011, I finally decide to open it up for a look. This MK20 is 10 years old and has only 62 dives.

Opening is easy, nothing is stuck.

Inside, there’s a lot of grease, I presume it’s Christo-Lube from the color of it. It was a factory-new item, so now I know SP was very liberal with grease at that time. The grease has not dried out: it still has the greasy/slippery feeling, and no solid residue that I can tell. So the claim that CL dries out after 2-3 years previously discussed needs a big qualifier.

In spite of the few dives it has, the HP seat is marked.

All the O-rings appear to be good and supple.

The G250 looks a bit worse. Because of all the rainbow colored O-rings, it must be a lot older that the MK20. Does anybody know the date when SP changed to the black ones? Anyway, most of them have become hard, and there're a few tiny nicks in the orifice.

Another hint at its age: it has an old style lever, and the seat is well marked.

As expected, everything cleans up nicely. After all, the rig is near new with only 62 dives in it.

I decide to replace all the O-rings, the orifice and the LP seat, but I keep the old HP seat just to see. And there's a little surprise: the IP is now 9.5 bar / 138 PSI. Yes, same piston, same seat, but higher IP. The only difference I know is the piston stem HP o-ring: I use a PU90 instead of the standard EP90.

The thing came with 2 shims under the spring and 2 in the seat retainer. I removed 1, and now the IP is back to 9.2 bar / 133 PSI, closer to where all my other rigs are.

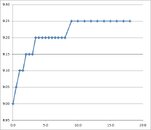

I'm leaving it pressurized for a while and report back next week with the final IP and cracking effort.

History: I bought this MK20 new from an LDS in June 2000, went on a dive trip, and then stored it in a clean, dry closet while I watched the kids grow. In August 2009, the kids got certified, I pulled it out, did a quick test, everything OK, and went on diving my merry way.

The G250 I’m not so sure; I have neither recollection nor paperwork that says when and where I got it. I found out later on it’s much older than the first stage.

Anyway, the last time I tested this rig was in January 2010: the IP was 9 bar / 131 PSI, no creep, and the recovery was instantaneous; the cracking effort was 24 mm / .94 inch of water. I thought about servicing it, but couldn’t find any good reasons for it, so I went on diving some more.

February 2011, I finally decide to open it up for a look. This MK20 is 10 years old and has only 62 dives.

Opening is easy, nothing is stuck.

Inside, there’s a lot of grease, I presume it’s Christo-Lube from the color of it. It was a factory-new item, so now I know SP was very liberal with grease at that time. The grease has not dried out: it still has the greasy/slippery feeling, and no solid residue that I can tell. So the claim that CL dries out after 2-3 years previously discussed needs a big qualifier.

In spite of the few dives it has, the HP seat is marked.

All the O-rings appear to be good and supple.

The G250 looks a bit worse. Because of all the rainbow colored O-rings, it must be a lot older that the MK20. Does anybody know the date when SP changed to the black ones? Anyway, most of them have become hard, and there're a few tiny nicks in the orifice.

Another hint at its age: it has an old style lever, and the seat is well marked.

As expected, everything cleans up nicely. After all, the rig is near new with only 62 dives in it.

I decide to replace all the O-rings, the orifice and the LP seat, but I keep the old HP seat just to see. And there's a little surprise: the IP is now 9.5 bar / 138 PSI. Yes, same piston, same seat, but higher IP. The only difference I know is the piston stem HP o-ring: I use a PU90 instead of the standard EP90.

The thing came with 2 shims under the spring and 2 in the seat retainer. I removed 1, and now the IP is back to 9.2 bar / 133 PSI, closer to where all my other rigs are.

I'm leaving it pressurized for a while and report back next week with the final IP and cracking effort.