- Messages

- 369

- Reaction score

- 60

nope. this didn't do the trick

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

Folks, what is the best method for separating the HP seat on MK 5 first stage from the seat cap with minimum damage? There seems to be a tiny hole in the back of the cap, but I am not sure if it goes all the way through to the seat. I tried sticking a needle in it but it hit a hard surface and didn't do much... Many thanks!

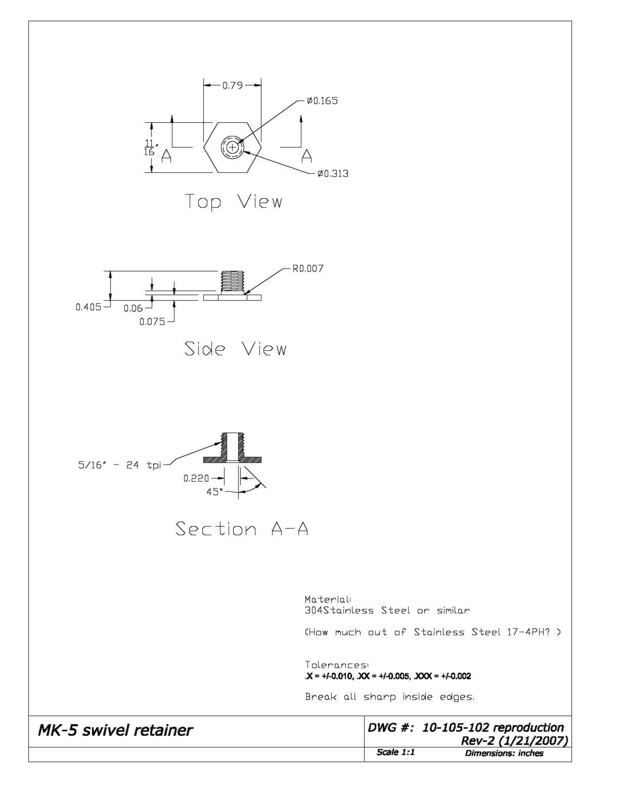

I was given the turret bolt specs recently.. if anyone is interested, I can have a batch made up in stainless steel... for those who need it.