Since we are showing our variations, I made one to fit in my Gauge Box (shown here:

DIY regulator test/flow panel).

Please forgive some blurry photos - I was trying to finish it up and grabbed my cell phone to get pics as i was building it. Add difficult lighting ...

I got it to fit in an inexpensive Raspberry Pi case.

Parts and construction ...

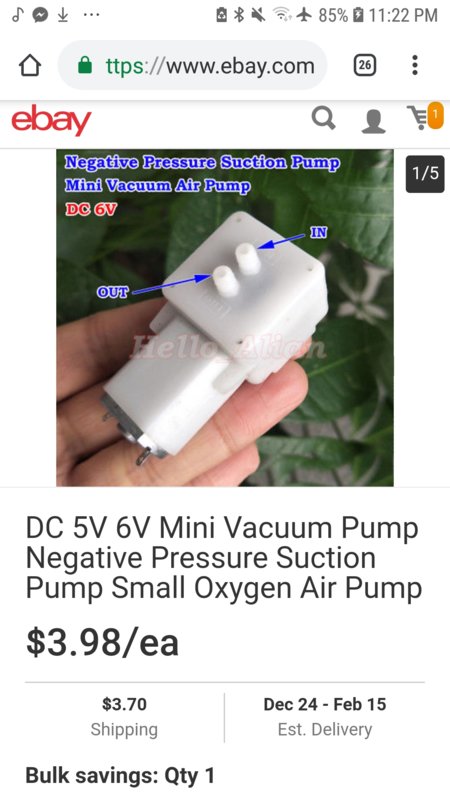

Vac/Motor (

DC 5V 6V 370 Mini Motor Air Pump Vacuum Pump Self-Priming Monitor Breast Pump US | eBay)

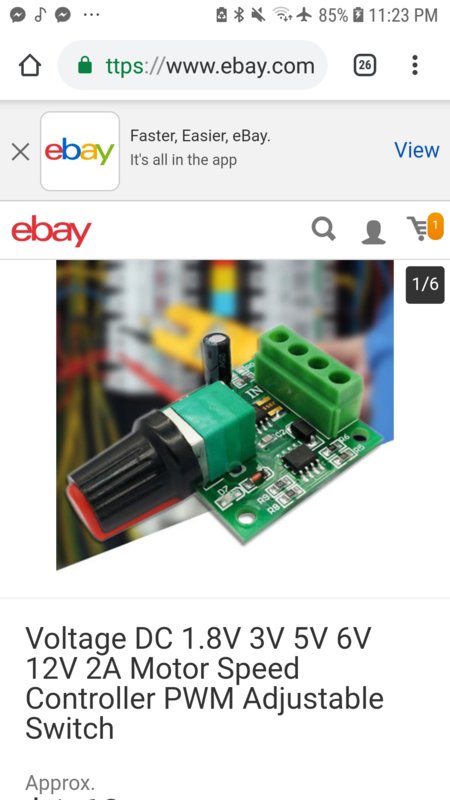

USB PWM board (

NOYITO 5V USB Fan Stepless Speed Controller Regulator with Switch Speed Modul... | eBay) used as a motor speed controller. I removed the USB-A Input port and swapped out the 4-pin USB-A output port for a 3-pin JST connector matching the motor (I had to jumper 2 adjacent pads to get the power over to the negative pin position on the JST.) This board also has a Micro-USB input which I am using.

Micro-USB extension/panel mount (

https://smile.amazon.com/gp/product/B06Y1M38S3) Second Picture shows the trimmed-back strain relief needed to fit things:

3/16" Barb-barb bulkhead fitting (

https://smile.amazon.com/gp/product/B07HF3RF1X):

Pi-Case (

https://smile.amazon.com/gp/product/B07PNB7JWP)

Drilled holes for air bulkhead fitting and Micro-USB panel mount:

Some more holes to mount the PWM-Board potentiometer:

Some mounting holes on the bottom to accept sheet-metal screws:

And enlarge a hole on the back for a locating stud and drill down a couple of the standoffs:

Now, to put it all together ...

Put in the locating screw and the air and power connections. Vac/Motor just squeezes in there nicely.

Connect the motor to the the PWM board and install it. Then hook up the air line to the vac pump:

Wind the Micro-USB extension cable and plug it into the PWM board input:

Give it a test, slap the cover on, and go have a beverage ...