Glue from Home Depot is

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quick Change Drysuit Seals

- Thread starter Ghost95

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

We have the SiTech seals installed on several suits. I have nothing to compare with but am happy with the SitechsThanks for your info. I noticed the difference in price too. I am leaning towards the SiTech seals so far.

- Messages

- 6,839

- Reaction score

- 5,970

- # of dives

- 2500 - 4999

That's because for PU rings you want a two pack glue

SI-Tech recommends a 2 part heat activated poly-urethane type glue....that allows the glue to be applied, the pieces to be properly aligned and then heat applied to activate the glue and create a bond.

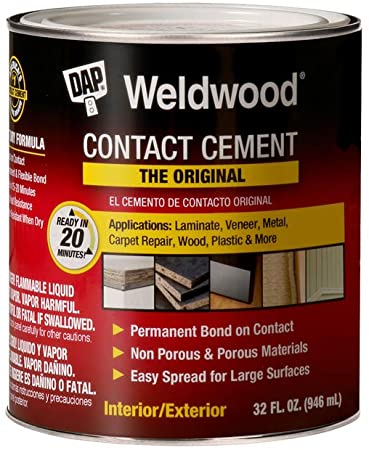

With contact cement, one has one chance to get thing correct as once the two glued surfaces touch the bond is formed between the glue. Weldwood is good stuff for some applications, I have used it to good effect to glue in custom minicell padding in whitewater kayaks and after 15 years the bond is still going strong...that being said, I am not so sure Weldwood contact cement is the best product for the application of gluing in a a wrist ring system...doable/workable? yes.....best and most effective? probably not.

Attached is the Si-Tech gluing guide for convenient reference.

-Z

With contact cement, one has one chance to get thing correct as once the two glued surfaces touch the bond is formed between the glue. Weldwood is good stuff for some applications, I have used it to good effect to glue in custom minicell padding in whitewater kayaks and after 15 years the bond is still going strong...that being said, I am not so sure Weldwood contact cement is the best product for the application of gluing in a a wrist ring system...doable/workable? yes.....best and most effective? probably not.

Attached is the Si-Tech gluing guide for convenient reference.

-Z

Attachments

SI-Tech recommends a 2 part heat activated poly-urethane type glue....that allows the glue to be applied, the pieces to be properly aligned and then heat applied to activate the glue and create a bond.

With contact cement, one has one chance to get thing correct as once the two glued surfaces touch the bond is formed between the glue. Weldwood is good stuff for some applications, I have used it to good effect to glue in custom minicell padding in whitewater kayaks and after 15 years the bond is still going strong...that being said, I am not so sure Weldwood contact cement is the best product for the application of gluing in a a wrist ring system...doable/workable? yes.....best and most effective? probably not.

Attached is the Si-Tech gluing guide for convenient reference.

-Z

Interesting. I believe the 2 part just cures faster? Correct? If you (@Ghost95) read through my thread you'd see that I ordered a $12 can of glue from DRiS. I had to layer it a lot (mine is a neoprene suit). The glue can be removed with some heat, which is nice in case you make mistakes or want to swap out later. I was recommended by a lot of people I could also use the DAP.

I meshed the 2 pieces together, rolled everything out, and then waited 24 hours or so before testing. I used the same glue to install a p valve. Both the rings and the valve work great, no leaks so far.

There may be some different glue in the UK, Seaskin was not allowed to ship theirs here, and maybe there's something better /faster in the US if you were doing multiple repairs a day, but what I used worked and I still have a ton left.

Interesting. I believe the 2 part just cures faster? Correct? If you (@Ghost95) read through my thread you'd see that I ordered a $12 can of glue from DRiS. I had to layer it a lot (mine is a neoprene suit). The glue can be removed with some heat, which is nice in case you make mistakes or want to swap out later. I was recommended by a lot of people I could also use the DAP.

I meshed the 2 pieces together, rolled everything out, and then waited 24 hours or so before testing. I used the same glue to install a p valve. Both the rings and the valve work great, no leaks so far.

There may be some different glue in the UK, Seaskin was not allowed to ship theirs here, and maybe there's something better /faster in the US if you were doing multiple repairs a day, but what I used worked and I still have a ton left.

I did read your thread. You did a great job.

I am not a glue expert. Here is a link to the glue Si-Tech sells but unfortunately the page indicates it is only available in Scandanavia:

Glue - Maintenance - Products - SI-TECH

The fine print on the cans state to activate the adhesive with a hot air gun.

I also found a link to the following SB thread from 2014 where the OP implies that Bostik 777 adhesive is heat activated:

Si Tech QCS rings adhesive (Bostik 2402?)

Reading through the thread, the OP used Bostik 2402.

What ever product is available that is suitable for bonding polyurethane is basically the prevailing recommendation.

From Si-Tech:

"If you use a heat activated glue; insert the Wrist Ring into the sleeve when the last layer of glue is dry. Place the glued surfaces together. Heat activate the glue, apply pressure and let dry. Reinforce the seams with tape to seal the edge. Apply pressure to all glued surfaces and allow to dry."

-Z

I did read your thread. You did a great job.

I am not a glue expert. Here is a link to the glue Si-Tech sells but unfortunately the page indicates it is only available in Scandanavia:

Glue - Maintenance - Products - SI-TECH

The fine print on the cans state to activate the adhesive with a hot air gun.

I also found a link to the following SB thread from 2014 where the OP implies that Bostik 777 adhesive is heat activated:

Si Tech QCS rings adhesive (Bostik 2402?)

Reading through the thread, the OP used Bostik 2402.

What ever product is available that is suitable for bonding polyurethane is basically the prevailing recommendation.

-Z

That's the issue that I ran into. There wasn't a lot available in the states that is elsewhere. I think you can get the bostick 2402 in the states, but it looks more expensive.

The upside is all my modifications can be removed and cleaned with mek, the downside is I couldn't leave the suit in a hot car...it might come undone. I just don't do that, lol.

I did read your thread. You did a great job.

I am not a glue expert. Here is a link to the glue Si-Tech sells but unfortunately the page indicates it is only available in Scandanavia:

Glue - Maintenance - Products - SI-TECH

The fine print on the cans state to activate the adhesive with a hot air gun.

I also found a link to the following SB thread from 2014 where the OP implies that Bostik 777 adhesive is heat activated:

Si Tech QCS rings adhesive (Bostik 2402?)

Reading through the thread, the OP used Bostik 2402.

What ever product is available that is suitable for bonding polyurethane is basically the prevailing recommendation.

From Si-Tech:

"If you use a heat activated glue; insert the Wrist Ring into the sleeve when the last layer of glue is dry. Place the glued surfaces together. Heat activate the glue, apply pressure and let dry. Reinforce the seams with tape to seal the edge. Apply pressure to all glued surfaces and allow to dry."

-Z

Also thanks for the approval, you helped a lot in that process.

I was also thinking, the PB-300, DAP weldwood, and DRiS glue can all be "activated" with heat. I have been told by a few (probably you as well) that if a leak should arise later down the road to heat the area and re-roll it before tearing everything apart. Should work to re-seal anything.

@Ghost95 , I don't think you can go wrong with any of the glues listed. The hardest part for me was the actual cutting of the neo seals off. Cutting a drysuit is scary stuff. After that it was relatively easy, albeit time consuming.

If you have the $$$ or an LDS local that can do it, have them do it. If not, maybe DIY is the way to go. Just move slow if you go that route and prep, prep, prep.

Good luck.

Thanks for all the replies guys. I'm still at least a few months out for the purchase so I'll keep up with the research on the different systems and how to remove and install old seals.

Similar threads

- Replies

- 1

- Views

- 208

- Replies

- 1

- Views

- 377

- Replies

- 2

- Views

- 631