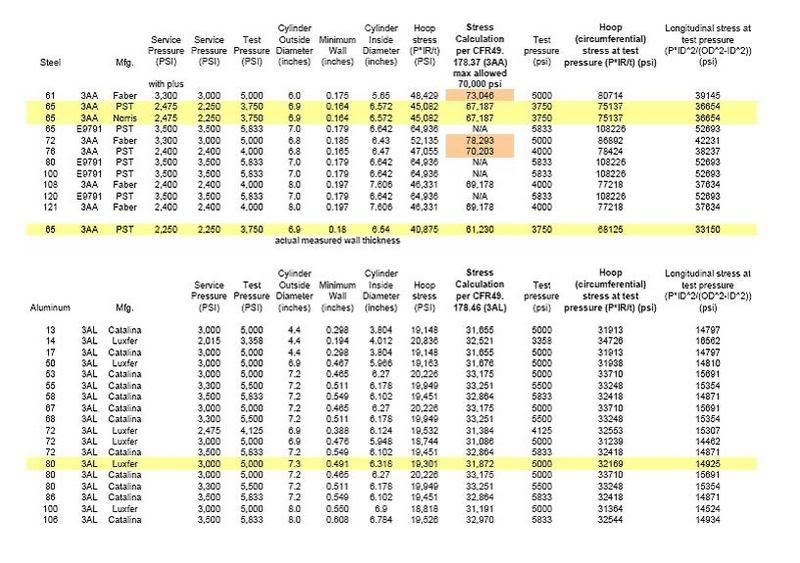

I had a steel 72 filled last night and when I got it home I found that the operator had filled it to nearly 3000 psi. That's the normal pressure for an AL80 isn't it?

Anyway, the tank was hydro'd a month ago and originally certified for 2260 I believe. When I got it back from the the LDS that performed the hydro they had filled it to 2600 psi.

Is overfilling a pretty common practice? How much danger am I with this 3,000 psi tank in my garage? I'm sure these tanks are engineered with a large safety margin...

How far have you pushed the envelope on this?

Anyway, the tank was hydro'd a month ago and originally certified for 2260 I believe. When I got it back from the the LDS that performed the hydro they had filled it to 2600 psi.

Is overfilling a pretty common practice? How much danger am I with this 3,000 psi tank in my garage? I'm sure these tanks are engineered with a large safety margin...

How far have you pushed the envelope on this?