Hi all. Came across this post online and thought I'd jump in. These spear guns are great. I've found they generally need some going over before going back into use, mainly setting the breach clearance.

I had some metal cartridges re made, and did a number of revisions, basically removing the disposable washer that usually sits between the charge and cartridge. I found them unsuccessful, as the explosion leaks back towards the breach, unlike the plastic sleeve which basically expands and seals, allowing the full charge to push the spear. Different ways of sealing the end I found effected things, ie too tough of a seal, expanded the sleeve.

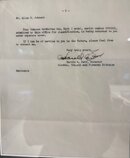

The charge too, needed to be the paper wadded ones, the ones available here with the crimped aren't suitable. We don't have access to the wadded charges here but I did get some from the US. I have some notes as I worked things out like the charges and so on. Two years back I sent Mark @ Tapmatic an email about them, he didn't have any more info for me for whatever I was asking; I shared a photo of one of mine in use to show his father Allan who designed them. He said Allan was very proud of the SMG spear gun and would be pleased to see one still in use. I'll try upload some images