You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do regulators fail?

- Thread starter Cthippo

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Cthippo

Contributor

Ok, I will keep using my Palantics and look for an IP gauge. I might even have one. I know I have a magnetic, but I think it is for the wrong range.

I would like to learn to service my regs, but knowing myself and how I learn I would prefer to do it in person. I guess when the current one starts to go I buy a new set for $160 and experiment on rebuilding the current ones.

Thanks for the wisdom, all...

I would like to learn to service my regs, but knowing myself and how I learn I would prefer to do it in person. I guess when the current one starts to go I buy a new set for $160 and experiment on rebuilding the current ones.

Thanks for the wisdom, all...

iointerrupt

Contributor

On regs without the collar seal why not use a paraffin or other agent to fill the threads since the anti-sieze would be outside the gas path?

Tribolube. Since I already got it out to grease the o-rings, I tend to put a small amount on any threads I run into.

Probably not recommended because all torque specifications are "dry", and now the threads are lubricated they'll torque differently. A tradeoff I'm willing to take for myself though.

Tribolube washes out in my experience and is not really a very good anti-sieze. But better than nothing. Salt water follows the threads in and does not come out even with a soaking. I want something for this purpose that does not wash out and does not allow water entry. I have used a thick silicone grease but even it allows some saltwater in over time.Tribolube. Since I already got it out to grease the o-rings, I tend to put a small amount on any threads I run into.

Probably not recommended because all torque specifications are "dry", and now the threads are lubricated they'll torque differently. A tradeoff I'm willing to take for myself though.

This is more dangerous to your gear than many appreciate. Generous thread lube can more than double the axial load on your threads, and does the opposite of what you expect.now the threads are lubricated they'll torque differently.

As the threads sit under load for a 2-year service interval, the lube is squeezed into the valleys between the threads, but the axial load remains.

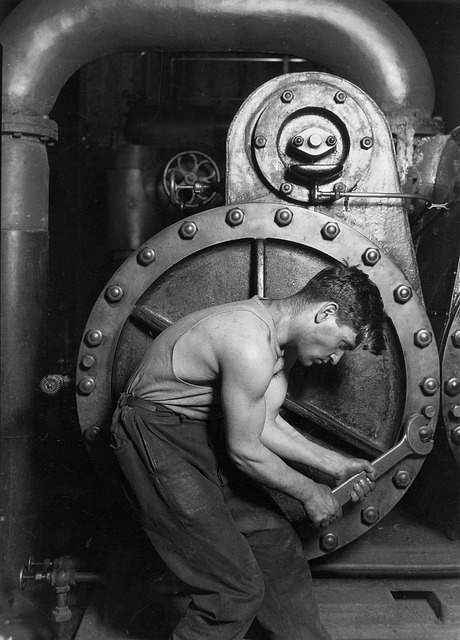

This can be the result of then trying to disassemble the bolt two years later:

You expected the lube to make it easier.

The lube disappeared from between the threads and the axial load was so great you chipped a hex point of the brass trying to loosen the bolt.

I cannot tell you the number of techs that make this logical assumption, that lube "helps". But threads that are engineered for a given axial load with dry threads should not be lubricated.

There are only a couple of manufacturers who engineer hi-torque connections like DIN bolts with lube specified. If the manual doesn't indicate lube, resist the temptation!

- Messages

- 8,602

- Reaction score

- 7,310

- # of dives

- 2500 - 4999

And this is why all my torque wrenches have only three settings and no gauge

depending on whether you hold those at the end the middle or the other end

depending on whether you hold those at the end the middle or the other end

Gone for diving

Contributor

I am sure its very controversial,

But I use a bit of fluid film on assemble, for most threads, scuba regulators and off road equipment.

Its food grade and tends to work well,

Yes poor engineering is a huge problem, the threads of hydraulic ram end caps are often exposed,

with the oring close to the oil, big mistake,

The oring needs to be at the top, so the oil is in the threads,

some use orings on both sides of the threads, personally not a fan that, but does seem to work.

But I use a bit of fluid film on assemble, for most threads, scuba regulators and off road equipment.

Its food grade and tends to work well,

Yes poor engineering is a huge problem, the threads of hydraulic ram end caps are often exposed,

with the oring close to the oil, big mistake,

The oring needs to be at the top, so the oil is in the threads,

some use orings on both sides of the threads, personally not a fan that, but does seem to work.

The engineering gets complicated. You lose a thread at the bottom when your create an oring boss there. You lose two threads at the top of most regulators because their body is curved at the bolt attachment point. With o-rings at both ends, there's suddenly not enough threads to grasp the soft brass...I wish they would do both o-rings. That would solve both problems. and cost less than $0.25 more.

L13

Contributor

You add extra brass to the body, that is where 80% of the extra cost goes (in bulk and extra o-ring is much less than $0.25).The engineering gets complicated. You lose a thread at the bottom when your create an oring boss there. You lose two threads at the top of most regulators because their body is curved at the bolt attachment point. With o-rings at both ends, there's suddenly not enough threads to grasp the soft brass...

L13

Contributor

Was the failure mode of the old design a catastrophic failure? It seems to me that it would be detected as a relatively benign failure usually at initial pressurization, and would still be the better choice overall (at least for me).But they had a higher incidence of extrusion, so most mfrs have gone to end o-rings at the bottom of the DIN or Yoke bolt.

Similar threads

- Replies

- 21

- Views

- 2,688

- Replies

- 1

- Views

- 304