We have no idea how long your filters are lasting, how many fills you are getting, how much filtration you have.

Possibly you have no no problems at all.

When we have photos and more info, we can help.

Providing your separators and P.M.V. are working properly... (without having these two things sorted out you will never, ever dry your air!)

Graeme mentioned what I have done to increase filter life and it is detailed below.

I am in the tropics, limited availability of everything, including filtration material at a pretty hefty premium. I have made a science of exactly this issue, going so far as to bake all of the moisture out of my M.S. weigh it with a scale accurate to .01 gram calculate its dry and saturated density, by allowing it to sit out in the open for 24 hours and checking how much weight is has gained...(always between 22.23 and 22.72 %)....

By the way, this stuff when baked down to close to 0% moisture content gets HOT just sitting in ambient air.

I have gotten more then triple the life out of my m.s. by running the h.p. air through a 15 meter long coil of 1/4" tubing in an ice water bath, prior to my final separator.

Same effect as the chiller, but I cannot count on electricity, but I can always find ice.

Ice does not break, and electricity to run a chiller would be as expensive here as the ice.

Island engineering !

Current separator inlet temperate in 18* c, down from around 44* c... (Ambient is 32*c)

knocking 26*c off the inlet temperature reduces the dew point, and dramatically increases the the amount of water that falls out in the separator.

I went from changing the filters every 13 hours to doing it every 50 when I change the compressor oil. Still at less then 20% R.H.

I am also running an mch-16 open frame...this whole fix cost less then $200 and a few hours and a used short tower that cost $200 and a small moisture separator that cost about $200, you can but similar separators in ebay. Used filter towers are hard to come by and you should know something about them before buying used.

Changing the filters when I change the oil works perfectly for me,(50 hours) though there are ways to improve, I have taken this compressor as far as I want to and will be concentrating on the k-14 that I am putting on my dive boat, taking all the lessons learned and really drying the air on the next one.

There are ways to improve on it, Tobin made a beautiful radiator, with multiple tubes in parallel, but I do not have his welding skill. I think this would help as it would slow he gas a lot,,I figured one time that the gas was spending about 1/2 of a second or less in that 15 meters of tube, hard to get it to give up all of its heat that fast.

You better be good with a tig welder if you are gonna go that route !

I am going to do this for my boat, but use JIC/flare fittings and manifold blocks five 1/4 inch tubes in parallel in ice water....

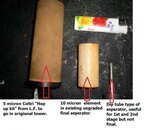

For the coltri, if you are running the cheesy small filter tower that comes with the integrated final separator..

This set up is an abomination from inception. Before I learned something about this subject, there was liquid water POOLED under the M.S. in the tower...Now when I vent the tower after the new added separator, no water.

There is a few drops of condensed oil on the stainless filter element, and a few on the bottom of the tower after 50 running hours. Standing water in the same chamber as the M.S. is simply unbelievable if you have played with the stuff you know it really wants to grab any water it can.

Ring up Mike at Lawrence Factor and get his "Coltri Hop Up Kit" this is a very fine, very large sintered bronze filter element that is installed in place of the cartridge in the filter tower, turning it into a huge super high efficient separator/ coalescer.(Pictures of sintered elements in the next post) I have one, but have yet to install it. Then add another tower or two...One 33" should get you 300-400 fills at around 32*C ambient. Still well within grade E.

My current system...output from compressor> 15 meters s.s. in ice water bath> a small separator with a 10 micron sintered element in it> check valve>coltri tower full of 300g of M.S. to an 18" tower with 200g of m.s. 60 g of A.C. and 50 G of hopcalite> 2 micron particle filter>10,20,30% moisture eye>P.M.V. at 150 Bar> 4 whip manifold.

I get over 400 fills on 500 g of m.s.... that means less .3 g of water and other stuff is getting by the coalescer per 1800 liter tank fill, I believe with some tweaking I could double this, but then I will be tempted to double the oil change interval..

This works !

Costs, peanuts....

Adding photos on the next post.

Thanks to swampdiver, ted green, tobin, craig a clark, iain middlebrooke, Mike Casey at Lawrence Factor, graeme

and a host of other who have patiently taught me enough that I have something useful to give back.

A picture speaks a thousand words and until you know it, the lingo, it takes thousands of words.

I have tried to post photos, but cannot right now.

Mine is an open frame mch-16 with the pitiful final separator/filter and all upgrades as discussed in my previous post. It is a 1995 model, same basic block.

Your enclosed one, if you are lucky will have an upgraded filter system with another separator and a dedicated filter tower....if so you in in really good shape.

I get the feeling you are a lot like me when I got started with this. In a remote place with a lot to learn and no one to teach you.

Nobody to service your compressor.

Don`t worry, its easy, and there is a lot of great help here.

I will try again later to out up my photos, but in the mean time can you post me one of your compressor block so I can see what you have for separators and filtration ?

P.M. sent with the link to Ted Greens article 'understanding compressors"

Oh somebody mentioned increasing the tube diameters..I did some back of the envelope calculations, and it works out that the speed reduction of the gas will not over come the reduced contact of the hot gas with the cooled walls.

To a point smaller is better, with the most heat lost in the first few meters, Tobin came up with a perfect analogy, a car radiator.

I can feel that the tube has cooled the gas the most in the first few meters, after that the tube stays uniformly cold.

The dwell time is important, but getting the hot molecules close to the cool walls is equally or more important.

This is actually some pretty advanced thermodynamics for people like me who know nothing about it, my next one will be a series of parallel tubes.