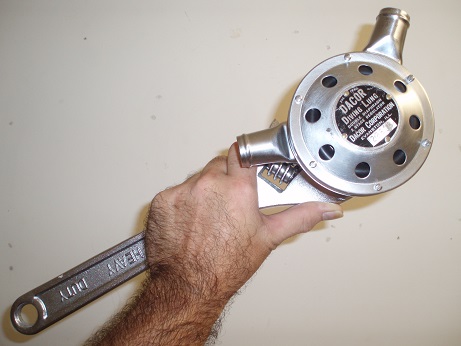

If it has not been modified, I would date it at approximately 1978. The 1975 model was my first reg, still in use, and it has just 2 LP ports. It appears unmodified in the 1977 catalogue:

http://www.angelofarina.it/Public/Scubapro/Scubapro-Catalogue-1977.pdf

The 1980 model has smaller holes in flooded chamber, and 5 LP ports, as there is a top one for maximum flow. So your should be a 1978 version, with large holes and no high flow LP port, and a joke not rated for 3000 PSI.

I have four MK5 first stages dating back to 1975-1980 (2 are mines, 2 of my wife), and all are working great. All parts are yet easily available, and Vintage Double Hose can provide ready-to-go service kits.

Only part difficult to find is the 3000 PSI joke (or the DIN conversion kit, which would be even better). On my 1975 model I installed the joke of a Cressi, which is almost identical to Scubapro 3000 PSI, but is rated at 250 bars.

I warmly suggest that you use the MK5 for your 109 2nd stage, and that you upgrade the 109 to a 156 (fully balanced, easier to tune and maintaining the tune for years). Again, Bryan at VDH has the conversion kit. And then downgrade your MK2 as the the first stage of your secondary (being historically correct, that should have been matched with a 108).

Well, of course I prefer to have two MK5 and two 109/156, in practice in our setup there is no clear difference between primary and secondary....