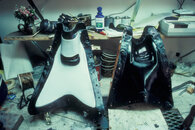

In 1982, We had not really worked out a good heel strap design since it was not needed. The Force Fin forces its self onto you foot. I will try to bring up this point because it is kind of important..think about it. Do a simple test for your fins..remove the heel srap in a pool test. Our first fun Photo shoot was Cayman Islands. Here you can see us all diving " STRAP FREE" . Was a simple way, slip on and just kick. Force Fin never came off.....#FORCEFINNERSUNITE

I've read that on your website and it's something I've not tried yet. I wonder if it would be same while frog kicking for example. One more thing to do on my post Covid bucket list.