bananafeller

Registered

Update for those interested

Here is a link to the Latest version of this handle: XTAR D26 Goodman Handle

@ChrisMBC and I have been using and testing them for over an year now

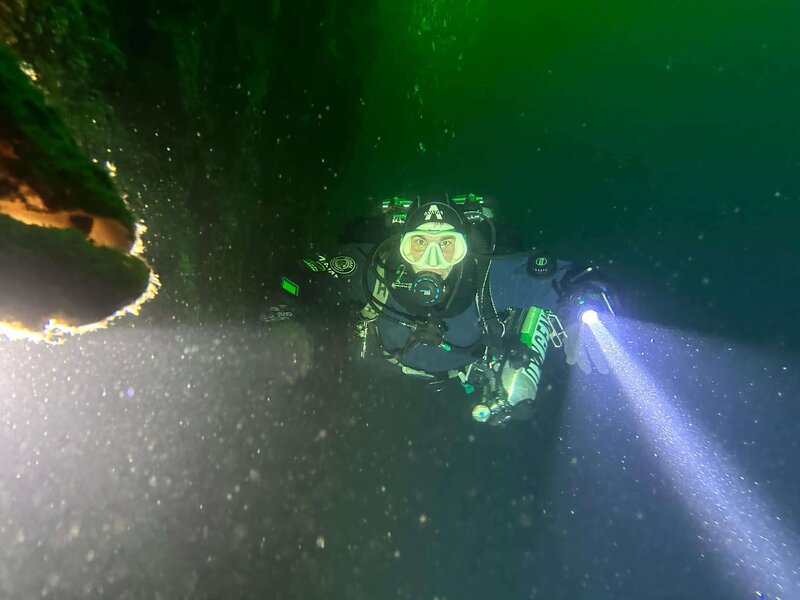

Some shots of the light and handle in use:

Here is a link to the Latest version of this handle: XTAR D26 Goodman Handle

@ChrisMBC and I have been using and testing them for over an year now

- The upper part is rock solid and works very well

- The lower "handle" portion has some weakness issues, that we overcame by making it out of aluminum (see attached photo).

- We are playing around with new stronger 3D printed designs but nothing is final yet

Some shots of the light and handle in use: