Just out of curiousity, how big is this nose cone?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Delrin hairline crack repair?

- Thread starter northernone

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Just out of curiousity, how big is this nose cone?

Bit bigger than an al80.

I’m no expert in plastics but the way they repair a tire is to open the hole up enough to get a plug into then reinforce with a patch on the inside. In this instance the pressure is on the outside so I’m thinking that if you take a small grinder to the crack just to open it up enough to pack epoxy in and then reinforce the outside with a large patch it should have the effect of not only fixing the crack but reinforcing the area as well.

lucca brassi

Contributor

Given the failure I think I would consider turning a replacement out of Aluminum instead. Both materials machine pretty easily.

density delrin vs aluminium is 1410 kg/m3 vs 2796 kg/m3 ( balance in water ? )

Important is also to get glue most even through crack without air bubles important is also just right viscosity and I think you need some help with vacuum on one side if gravity don't work enough.

PS: POM or Teflon similar materials is NOT as a TIRE ! .

.

Magic word is low surface energy glue

density delrin vs aluminium is 1410 kg/m3 vs 2796 kg/m3 ( balance in water ? )

Important is also to get glue most even through crack without air bubles important is also just right viscosity and I think you need some help with vacuum on one side if gravity don't work enough.

PS: POM or Teflon similar materials is NOT as a TIRE !

.

.Magic word is low surface energy glue

Last edited:

density delrin vs aluminium is 1410 kg/m3 vs 2796 kg/m3 ( balance in water ? )

Good point. Aluminum has a much higher yield but you would have to make a solids model on a CAD/CAM system and perform FEA (Finite Element Analysis) to determine how much wall thickness could be reduced to get the same submerged weight without compromising the depth rating.

You don't need a computer to calculate how much heavier an Aluminum version would be in water so that might be a good first step. Depending on the wetted volume of the part, the difference might be small enough to be OK.

Rred

Contributor

Custom turning an aluminum billet (of the proper alloy to play nice in seawater!) will probably cost more than buying a new nosecone, or a dead scooter to scavenge one from.

"Delrin" tends to be a misused term, there are a number of similar materials and the adhesives for pretty much all the engineering plastics are very picky about what they stick to. I'd want to make Real Damned Sure that part really is Delrin. Not ABS, Not Cycolac, not anything else.

FWIW.

"Delrin" tends to be a misused term, there are a number of similar materials and the adhesives for pretty much all the engineering plastics are very picky about what they stick to. I'd want to make Real Damned Sure that part really is Delrin. Not ABS, Not Cycolac, not anything else.

FWIW.

lucca brassi

Contributor

I also hard believe that you would crack nose cone made from delrin because material is very tough.

Scooter parts - Nose cone for Gavin scooter - ScubaSupport.nl

i think material is original HDPE

Scooter parts - Nose cone for Gavin scooter - ScubaSupport.nl

i think material is original HDPE

"Delrin" tends to be a misused term,...

For sure, any dull black and opaque plastic tends to be called Delrin, which is DuPont's tradename for Polyoxymethylene or POM. It isn't as nice to machine as brass, but a solid second.

Scooter parts - Nose cone for Gavin scooter - ScubaSupport.nl

Wow, good find. Well done sir.

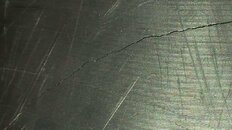

Following up here. I've been enjoying the research and appreciate the education on plastics and bonding agents.

Due to currently being in Mexico turns out my adhesive options are very limited. Nothing remotely appropriate to be had, going with suspecting the material is Derlin as I came across an old advertisement for the scooter (Salvo MOJO) where one of the guys mentioned it (unsure if it's technically accurate, carves nicely, smooth and takes heat well...) Slippery new material I need to learn more about. Googling the terms in this thread and digesting the links.

This leads me to looking at the problem again. Hairline crack was external... I assumed it simply continued inside... Turns out it is leaking up the thread of a pair of bolts holding on a trim weight. I should have looked closer.

This morning I've carved a groove into the interior surface, encapsulating an oring. Slightly over tightening it appears and extruding due to the wrong size of head... Still suspect it will hold pressure.

Testing it this afternoon.

I can't see where the end of the crack leads internally so unfortunately I haven't drill stopped it. Hoping it doesn't continue and lead to an actual breach.

Looking around for a machinist up to the task who won't charge a fortune.... Times like this I miss my lathe (3 moves ago I dismantled my rough shop and now have very limited tools) getting salt water friendly aluminum might be ok here, plenty of marine supply and a few fabrication shops.

Attached are a few photos to make sense of my ramblings.

Thank you all again,

Cameron

Due to currently being in Mexico turns out my adhesive options are very limited. Nothing remotely appropriate to be had, going with suspecting the material is Derlin as I came across an old advertisement for the scooter (Salvo MOJO) where one of the guys mentioned it (unsure if it's technically accurate, carves nicely, smooth and takes heat well...) Slippery new material I need to learn more about. Googling the terms in this thread and digesting the links.

This leads me to looking at the problem again. Hairline crack was external... I assumed it simply continued inside... Turns out it is leaking up the thread of a pair of bolts holding on a trim weight. I should have looked closer.

This morning I've carved a groove into the interior surface, encapsulating an oring. Slightly over tightening it appears and extruding due to the wrong size of head... Still suspect it will hold pressure.

Testing it this afternoon.

I can't see where the end of the crack leads internally so unfortunately I haven't drill stopped it. Hoping it doesn't continue and lead to an actual breach.

Looking around for a machinist up to the task who won't charge a fortune.... Times like this I miss my lathe (3 moves ago I dismantled my rough shop and now have very limited tools) getting salt water friendly aluminum might be ok here, plenty of marine supply and a few fabrication shops.

Attached are a few photos to make sense of my ramblings.

Thank you all again,

Cameron

Attachments

Last edited:

Similar threads

Trip Report

September Bonaire Trip - Captain Don's Habitat

- Replies

- 10

- Views

- 983

- Replies

- 12

- Views

- 3,063

- Replies

- 17

- Views

- 5,111

- Replies

- 14

- Views

- 4,756

- Replies

- 96

- Views

- 14,195