Scubadoo72

Contributor

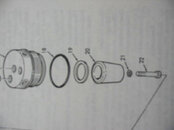

Well...you have successfully lost me..lol. I will snap a pic of my filter system and one of the cartridge. Something that I would plumb inline to replace the existing would be great, but I really don't want to spend more than the compressor is worth either...I can slow fill and change filters more often if necessary...I know the fellow I got it from used it for years just the way it is.

edit..I should add, that yes, my filter does drop in pressure when I release the water separator..but I also try to clear the line with freshly pumped air before connecting to my tank again..if that makes any difference..

edit..I should add, that yes, my filter does drop in pressure when I release the water separator..but I also try to clear the line with freshly pumped air before connecting to my tank again..if that makes any difference..