Jimmer

Contributor

Normally the auto stop switch which installed on the shop compressors have combined with a unload valve, when the tank pressure reached to the set pressure the auto stop switch will trigger and cut off the power for the drive motor until the tank pressure dropped to a certain level the switch will reset and turn on the motor again, when the switch getting to rurn off it when the pressure reached to the set point, at the same time the working arm of the switch will also press the unload valve to release the pressure which remain in the section between the compressor discharge port to the check valve of the tank to help the compressor can be get a easy start up.

We are not call it as auto drain valve but just unload valve.

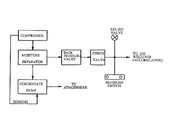

I understand how all that works, as I've built a couple of 60 and 26 gallon shop compressors for myself and friends. I'm interested in how these applications of pressure switches and unload valves specifically apply to high pressure scuba compressors.