Michel Dumont

New

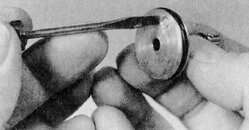

Hello there, I have a SRB3600 Sherwood reg and the positive pressure one way valve is not functioning on the first stage piston. Besides using an ultrasonic cleaner, what else can I do to allow air to flow through again? I have attached a picture taken from the service manual showing the positive air purge valve on the piston, although the manual says that absence of bubbles proves the system is not working, there is no suggestion on how to clean or repair. Is that piston fixable?

Many thanks

Many thanks