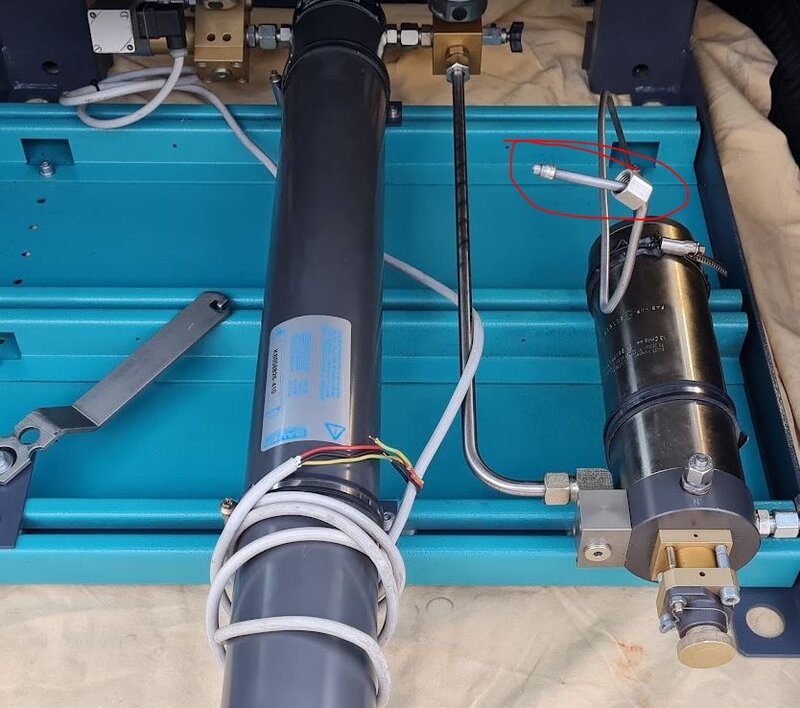

I have bought a Bauer K14 compressor. The unit was disassembled earlier and now I need an advice how to connect the ADV.

It has the old four knob ADV and I suppose that the drain port of the water/oil separator goes to the top of the ADV. But want to be sure, somebody might has the same setup.

The shape and the length of the steel tubes are a bit weird and do not know how the filter system was positioned next to the compressor unit....

It has the old four knob ADV and I suppose that the drain port of the water/oil separator goes to the top of the ADV. But want to be sure, somebody might has the same setup.

The shape and the length of the steel tubes are a bit weird and do not know how the filter system was positioned next to the compressor unit....