The boom factor should be your biggest concern.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Analyze nitrox after compressor

- Thread starter Björn Jakobsson

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

rolanddiver

Registered

I see the OP's point.I don't know about the DiveSoft Solo but my DiveSoft analyzer is actually capable of shutting down the compressor (or closing a solenoid valve in the O2 line, or do both) if the actual mix at the intake differs from the desired one.

VR

Roland

VR

Roland

rolanddiver

Registered

I would be scared sh.itless pumping nitrox by only monitoring the output of the compressor and hoping that my O2 regulator works as intended. By the time you see the deviation, it might be too late. it's kind of like Russian roulette. You only get lucky so many times.. Just my two cents.

Roland

Roland

I just use my decanting whip to bleed O2 into the inlet hose. Leave the high pressure fill bleeder open and test with my ATA analox when the mix is right ( within a minute) close the bleeder and open the tank valveHow long does it take to get the mix right initially? Do you find there's much of a delay? Why measure at the hp side? Convenience? It seems that an intake sensor would be easier and have less latency.

Björn Jakobsson

Registered

tmassey

Contributor

I just use my decanting whip to bleed O2 into the inlet hose. Leave the high pressure fill bleeder open and test with my ATA analox when the mix is right ( within a minute) close the bleeder and open the tank valve

@mac64 , your tolerance for risk is... noticeable — and not just in this thread. You do you, dive and let dive, etc. But I think there are few who would consider waiting until well *after* a potentially explosive mix of O2 has made its way through your compressor to be a best practice, and doubly so just to avoid adding at most less than $150 in parts... This is in no way an argument to get you or others to change; merely to opine for others where your choices might land on the risk/reward scale. To each their own.

I have a Vandragraph Tec-Ox analyzer as well. Would it be possible to insert the blue part somehow is the pipe, because that would put it in the middle of the flow to the compressor, or is that overkill/not sufficient?

In its current configuration it’s not ideal, but it includes all of the raw ingredients that you need to make exactly what you need. For example, the tiny opening that is designed to have gas directly forced into it won’t really work in your intake stick. But take that off, and it probably does. Of course, then the display is unreadable. But if you were to extend the leads between the sensor and the display, you’d be able to turn the display around.

Doing that, you would have the DIY version of exactly what I described: a mini ox 3000 with an external oxygen sensor!

If it were me, I would either steal the oxygen sensor out of what you have and add it to a mini ox, or I would sell the one you have as-is to someone who would want to use it as-is for its proper job of checking tanks, and use that money to cover the majority of the expense of buying exactly what would best fit my needs!

Having said that, in the past when money was very tight, I used to repurpose things all the time. It can be made to work. Sadly, most of the time, I ended up eventually spending almost as much money as the real tool, and got a lot less of the proper function and value of the real tool. When the real tool is all of $50 every day on eBay, there’s not a lot to save.

I would still recommend you have an analyzer at end of your nitrox stick just before your compressor intake to make sure you're not accidently pumping 40%+ into your compressor.

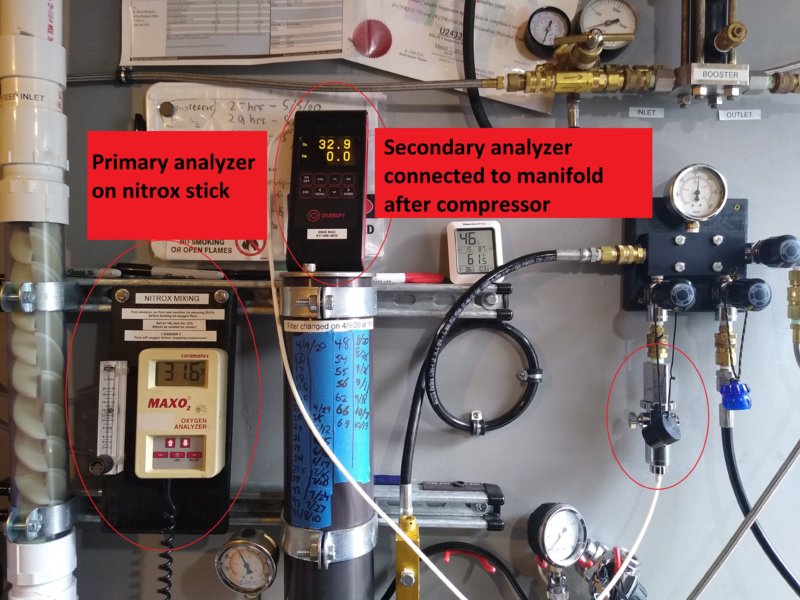

I do both. It's just another way for me to verify the accuracy of mix and make sure I'm seeing 32% on my manifold after the compressor. I typically leave 32% in my filter stack but there are times when I need to blend air or lesser mixers. It's not a huge delay but maybe ~3-5 minutes for me to start seeing 32% on my whips. When I first built my nitrox stick I had an O2 leak on my input side. Analyzing on output side was helpful for troubleshooting leaks.

I have my compressor going to a secondary filter stack with priority valve that goes out to a 5 port manifold. I use Parker quick disconnects (same that I use on my booster) connectors on my manifold to make everything interchangeable. I have a Parker QD to DIN fitting adapter. I then use a Divesoft DIN connector (flow restrictor) to sample gas on my Divesoft analyzer.

Obviously you can build another flow restrictor or use a different one but this works for me.

EDIT: it wasn't exactly expensive. I bought a cheapo Max O2 analyzer on eBay for $25USD and soldered in the headphone jack for O2 cell.

I do both. It's just another way for me to verify the accuracy of mix and make sure I'm seeing 32% on my manifold after the compressor. I typically leave 32% in my filter stack but there are times when I need to blend air or lesser mixers. It's not a huge delay but maybe ~3-5 minutes for me to start seeing 32% on my whips. When I first built my nitrox stick I had an O2 leak on my input side. Analyzing on output side was helpful for troubleshooting leaks.

I have my compressor going to a secondary filter stack with priority valve that goes out to a 5 port manifold. I use Parker quick disconnects (same that I use on my booster) connectors on my manifold to make everything interchangeable. I have a Parker QD to DIN fitting adapter. I then use a Divesoft DIN connector (flow restrictor) to sample gas on my Divesoft analyzer.

Obviously you can build another flow restrictor or use a different one but this works for me.

EDIT: it wasn't exactly expensive. I bought a cheapo Max O2 analyzer on eBay for $25USD and soldered in the headphone jack for O2 cell.

Attachments

@mac64 , your tolerance for risk is... noticeable — and not just in this thread. You do you, dive and let dive, etc. But I think there are few who would consider waiting until well *after* a potentially explosive mix of O2 has made its way through your compressor to be a best practice, and doubly so just to avoid adding at most less than $150 in parts... This is in no way an argument to get you or others to change; merely to opine for others where your choices might land on the risk/reward scale. To each their own.

In its current configuration it’s not ideal, but it includes all of the raw ingredients that you need to make exactly what you need. For example, the tiny opening that is designed to have gas directly forced into it won’t really work in your intake stick. But take that off, and it probably does. Of course, then the display is unreadable. But if you were to extend the leads between the sensor and the display, you’d be able to turn the display around.

Doing that, you would have the DIY version of exactly what I described: a mini ox 3000 with an external oxygen sensor!The thing I appreciate about the mini ox is that it has a larger display, and also a high limit alert with blinking lights and loud beeps. I wouldn’t pay much for that feature, but if it came along for the ride, it’s nice to have.

If it were me, I would either steal the oxygen sensor out of what you have and add it to a mini ox, or I would sell the one you have as-is to someone who would want to use it as-is for its proper job of checking tanks, and use that money to cover the majority of the expense of buying exactly what would best fit my needs!

Having said that, in the past when money was very tight, I used to repurpose things all the time. It can be made to work. Sadly, most of the time, I ended up eventually spending almost as much money as the real tool, and got a lot less of the proper function and value of the real tool. When the real tool is all of $50 every day on eBay, there’s not a lot to save.

I picked up a used miniox 3000 and a new sensor, I think $140 total? Maybe $150...haven't had a chance to build a stick yet, but I'm glad to see a few people using them.

I would still recommend you have an analyzer at end of your nitrox stick just before your compressor intake to make sure you're not accidently pumping 40%+ into your compressor.

I do both. It's just another way for me to verify the accuracy of mix and make sure I'm seeing 32% on my manifold after the compressor. I typically leave 32% in my filter stack but there are times when I need to blend air or lesser mixers. It's not a huge delay but maybe ~3-5 minutes for me to start seeing 32% on my whips. When I first built my nitrox stick I had an O2 leak on my input side. Analyzing on output side was helpful for troubleshooting leaks.

I have my compressor going to a secondary filter stack with priority valve that goes out to a 5 port manifold. I use Parker quick disconnects (same that I use on my booster) connectors on my manifold to make everything interchangeable. I have a Parker QD to DIN fitting adapter. I then use a Divesoft DIN connector (flow restrictor) to sample gas on my Divesoft analyzer.

Obviously you can build another flow restrictor or use a different one but this works for me.

EDIT: it wasn't exactly expensive. I bought a cheapo Max O2 analyzer on eBay for $25USD and soldered in the headphone jack for O2 cell.

View attachment 652977

Where did you buy or how did you build the mixer in the housing...looks like a nice setup.

Where did you buy or how did you build the mixer in the housing...looks like a nice setup.

It's a clear static mixing tube from TAH Bell Static Mixers - StatiFlow Clear Mixers You can buy static mixers in various places but some get pretty expensive. I admit It's total overkill for this application but it looks "cool."

it's about $80 plus shipping

Static Mixer 2" ID "clear static mixer" PVC process mixer biodiesel | eBay

CLR-200-2ST-MM40 2" clear; Schedule 40 2 Stage 9-60 GPM Max PSI 140

20" long with 2" diameter with NPT ends.

By the time my O2 indicator at the compressor inlet told me my mixture was too high the mixture would already be in the compressor. My flowmeter is the initial indicator that tells me the mixture is safe t feed to the compressor.I would be scared sh.itless pumping nitrox by only monitoring the output of the compressor and hoping that my O2 regulator works as intended. By the time you see the deviation, it might be too late. it's kind of like Russian roulette. You only get lucky so many times.. Just my two cents.

Roland

Similar threads

- Replies

- 0

- Views

- 141

- Replies

- 7

- Views

- 1,087

- Replies

- 2

- Views

- 530

- Replies

- 9

- Views

- 742

- Replies

- 11

- Views

- 1,034