Okay... to continue... The conclusion to this argument is that the Alkin removes MORE moisture and oil vapor before it gets to the filter media. And this makes the filter media last longer. Which also would explain why the Bauer humidity/temperature tables probably don't apply to the Alkin.

Proving it - I tried the viewport system that has a window and a disk inside that changes color with moisture... Like the strips, it's supposed to change from blue to pink when your moisture content is too high. This I found absolutely useless. If I started with it pink and put a brand new filter cartridge on, it would stay pink. If I started with it blue and put a used filter cartridge on, it would stay blue.

Home Made Moisture Checker - A friend on another forum came up with this. The blue dot strips are cheap. The container was made from a household water filter and runs

UN-pressurized. Anyway, I put the dot strip in it with all of the dots showing pink from being out in the summer humidity. I hooked up the fill whip and ran the compressor and within ONE MINUTE it turned all six dots blue... Which means the Alkin W31 was pumping NICE DRY AIR and the filter media is still good. I tried it again with a used Lawrence Factor clear plastic filter and got the same result. And again with a used Lawrence Factor cartridge that's made for the Bauer... Same result. After each test, I unhooked and let the humid air back into the container and all of the dots turned pink again. I have to conclude that the Alkin is pumping nice dry air and all three of those cartridges have plenty of life left in them.

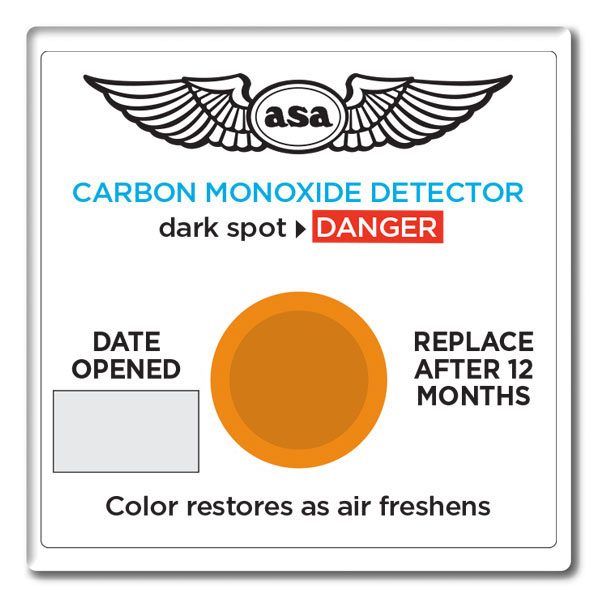

What about Carbon Monoxide? Well, since the viewport-with-disk system didn't work, I don't trust it to work with a Carbon Monoxide disk. BUT, I found the same CO detecting disk for use in private airplanes. I'm going to mount this in the same homemade container to check for CO.

Procedure for Use - Remember this is NOT PRESSURIZED. So you can't use it while filling a tank. I use it before I start filling a tank... To check and assure that the filter media is still good. Once I've done that, I disconnect the fill whip from the checker and hook up directly up to the tanks I'm filling. It's no problem to periodically re-check the air during fill sessions. Just swap the fill whip to the checker.

A Better Way - A couple of the others on that forum (who are much smarter than me) came up with ways to run a similar moisture checking system while filling a tank. But I'm happy keeping it simple.