......It looks like I'm going to be taking an AIR 2 apart in the near future.

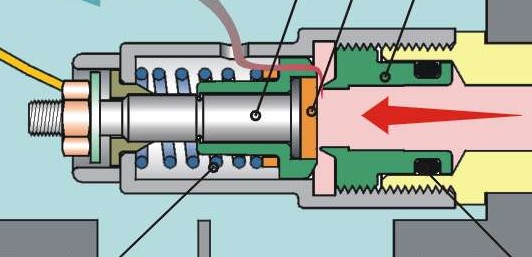

OK, my memory was playing tricks on me, but now that I've had a chance to do a bit of hands on work, I have a better understanding of PC's problem and why it led to a damaged poppet.

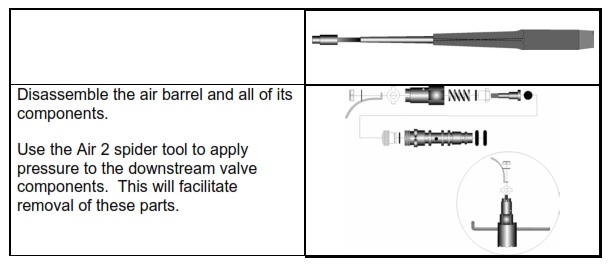

Usually, when you disassemble the two parts of the air barrel, the orifice comes out:

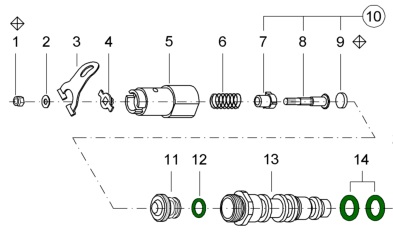

If the orifice is stuck in the air barrel, from now on I'll remember to first torque down the nut (item 1) to give the parts more clearance, then use the largest Easy Out possible to extract the persistent orifice. Going back in, lube all the threads to make life easier next time.

While getting a handle on this issue, I had a problem getting consistent cracking pressure. After flipping, then changing the seat, I took everything apart again and had a close look at some of the other parts in the linkage. The washer (item 2) was deformed, and I also replaced the insert (item 4) as it had a bit of a groove in the area that the lever acts on.

Neither of these parts are included in the service kits, and not called for as annual replacements.

......more lessons learned.

BTW, thanks for the fine diagrams PC, please let us know how your project is going.

Couv