William Farrell

Registered

Long ago I was at a Northern CA scuba shop looking at Tekna regulators. I asked the sales guy if I could service it myself. "No way," he said, "it's extremely complicated and you'd probably mis-adjust it and die."

Well, some years later I decided to find out. I've been buying used Teknas on eBay for the past several months and restoring them---when possible. The design is quite unique.

The valve bodies came in brass and plastic. People tend to look down on the plastic ones and I don't know why---they're lighter, will never corrode, and have exactly the same insides. Here's one of each:

Let's take the brass one apart:

And take off the circlip:

Remove the rubber spacer:

Two holes on the top and a bolt on the bottom:

With a socket on the bolt and needlenose pliers in the holes, we can take it apart:

And here's the innards:

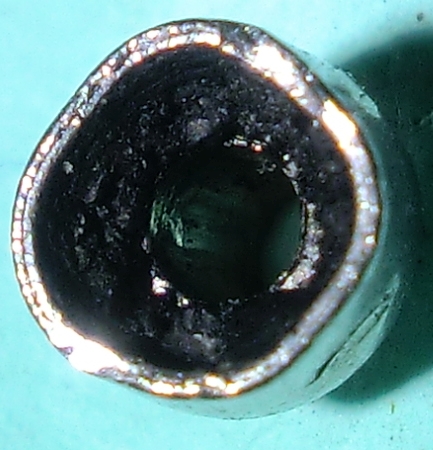

Bolt on the left, strong spring to keep things together, tiny spring to keep the needle poppet square on its seat. Looking inside the housing we can see the seat:

And finally the poppet. I don't know what else to call it. It's a miniscule rubber donut on the needle that doesn't lift straight off the seat but rather tilts off when you create a vacuum by inhaling:

This one is in good shape, as were about 50% of the dozen or so I worked on. Here's one that's not so good (I pulled this one off the needle):

An interesting system---very little that can go wrong, and zero possibility of adjustment. It either works or it doesn't. I've tried replacing the degraded rubber donuts with all sorts of stuff---o rings, teflon, gaskets, etc.---but I haven't found the magic material yet. Some are too hard: the poppet won't seal on the seat and the regulator free flows. Some are too soft: the regulator holds pressure, but it takes too much effort to tilt the poppet off the soft seat to start airflow. I'll find it eventually.

So there you have it, the inside story on a long-forgotten technical marvel. Hope you enjoyed it.

Well, some years later I decided to find out. I've been buying used Teknas on eBay for the past several months and restoring them---when possible. The design is quite unique.

The valve bodies came in brass and plastic. People tend to look down on the plastic ones and I don't know why---they're lighter, will never corrode, and have exactly the same insides. Here's one of each:

Let's take the brass one apart:

And take off the circlip:

Remove the rubber spacer:

Two holes on the top and a bolt on the bottom:

With a socket on the bolt and needlenose pliers in the holes, we can take it apart:

And here's the innards:

Bolt on the left, strong spring to keep things together, tiny spring to keep the needle poppet square on its seat. Looking inside the housing we can see the seat:

And finally the poppet. I don't know what else to call it. It's a miniscule rubber donut on the needle that doesn't lift straight off the seat but rather tilts off when you create a vacuum by inhaling:

This one is in good shape, as were about 50% of the dozen or so I worked on. Here's one that's not so good (I pulled this one off the needle):

An interesting system---very little that can go wrong, and zero possibility of adjustment. It either works or it doesn't. I've tried replacing the degraded rubber donuts with all sorts of stuff---o rings, teflon, gaskets, etc.---but I haven't found the magic material yet. Some are too hard: the poppet won't seal on the seat and the regulator free flows. Some are too soft: the regulator holds pressure, but it takes too much effort to tilt the poppet off the soft seat to start airflow. I'll find it eventually.

So there you have it, the inside story on a long-forgotten technical marvel. Hope you enjoyed it.