great info, thanks.

i'm told the gold topped one is just another separator. it's larger than normal, which is good, but still not purification. you happen to know where to look to figure out how to change the internals of the separators, or if i even need to. i figured they get clogged up after years of service and probably need to be changed out. but i don't know where to start with regard to opening either up or where to buy the parts. and the purification system would just plumb in downstream of the separators anywhere? or would i take out one of the separators? not much room on my frame to mount another thing without bolting to the outside somewhere. which is fine if it doesn't matter, unit just sits in my garage and has plenty of room.

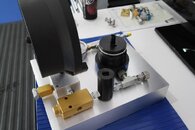

There isn't much to the separators. They are mostly empty chambers that store liquid water/oil. It's a good idea to open them though since it probably hasn't been done in ages. Your intermediate separator is similar to mine at least on the outside. The textured collar directly above the blue sticker should unscrew from the top part. Mine will unscrew by hand, but you might need a strap wrench or similar to get it loose the first time. I have no idea how to get into your final separator (gold top). Once inside, the separators you want to look for pittting or major courosion (like VIP on a tank). Hopefully there isn't any. Mine are just empty chambers and centrifugal force is used to separate liquid from gas so nothing to clean really. There might be a sintered bronze filter inside that may need some cleaning to get deposits off. I'm not sure what is good for cleaning sintered bronze filters, but you could try white vinegar. If you use anything to clean the inside of these machines make sure you wipe/wash away all the residue. Try to avoid "heavy duty" chemicals.

You can add the purification system anywhere after the compressor's final separator and before the fill whip(s). Mine is not mounted to the compressor/frame. The purification system should consist of the following...

Check valve - A one way valve that prevents the entire purification tower from de-pressurizing when the final separator's drain is opened. This is both for efficiency and because most purification towers are not designed for such rapid de-pressurization/pressurization cycles. Separator chambers are.

Pressure gauge - to monitor purification tower pressure and to assist with setting up the priority valve.

Bleed valve - to release air from the purification system when it's time to change the filter cartridge.

Filter tower/chamber - holds the filter cartridge. Larger is better for the most part.

Priority valve - AKA backpressure valve. This prevents air from going downstream (to the fill whip) until it has reached a minimum pressure. Usually set between 1800 and 3000 PSI. This is very important as the filtration will not work correctly without backpressure.

with regard to the oil, are you saying add oil until its in the site glass? cuz the site glass is pretty far up the block, that's a whole lot of oil. *edit* nm, while reading the manual it reminded me of the dipstick, which has a level. duh.

On my compressor (a Bauer Mariner II) the site glass has a min and max line. If yours has a dip stick then use that instead. They do take a lot of oil though. Mine has a 2.8L oil capacity.

Since you probably don't know what oil you have in the compressor you might want to read this thread...

http://www.scubaboard.com/forums/co...ding-systems/412702-bauer-compressor-oil.html

I had the same problem of an unknown oil. I decided to use Bauer SL800 synthetic oil. I did an oil change to the new oil, ran the compressor for 10 hours (not all at once though) to clean out the old oil junk and did not use the gas (just let it dump from the final separator), did another oil change, and then connected the purification system and started pumping my own tanks.

sucky thing is i filled up a couple tanks as it is when i was testing it out. can i just blow the air out or do i need to get em visually inspected again?

Opening the tanks would be the only way to know for sure. At the very least, I would drain them down to ~100 PSI in case there is moisture inside and get them refilled with dry air. No chemical filtration = wet (and oily) fills. Get them 02 cleaned again if they are ever going to be Nitrox filled using partial pressure blending.

with regard to you not recommending the triplex, i was told of another option. besides just swapping the final separator(gold one) out with a triples or super triplex, i can just add on a filter tower. now with those a final separator is required, but since i already have one i could do it. the filter tower cartridges are about half the price of the triplex cartridges, but may not last as long. which would be better, both performance wise and value wise? and if adding a cartridge and a p31 super triplex was the exact same price, which would you recommend?

I have a Triplex P0. The filter cartridge is tiny. It would work fine while it's within it's rated life (which in Florida temps is about half of the nominal CuFt rating). The Triplex P31 is an improvement, but it's an expensive unit and it's filter size isn't anything amazing. I bought a 33" filter tower as an add on and connected it downstream of the P0. The P0 is basically just a final separator for me now.

33" Filter Tower August Industries Inc.

I use these cartridges...

Filter Cartridge, MAKO PD-1803 August Industries Inc.

I can pump ~13,000 cuft of air (conservative) in Florida temps before the filter needs changing and get cleaner gas since the filter volume is much larger (the gas is in contact with the filter media longer). With the P0 it would be more like 1,300 cuft of air (might be pushing it). The bigger filters are a much better value and less maintenance.