Mr Carcharodon

Contributor

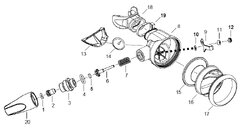

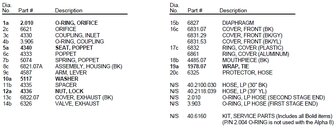

Am I correct in understanding that this inline tool is used to adjust the position of an orifice, moving in or out, so as to control the 2nd stage from free flowing? I read another way is to use a flat head screwdriver that would fit the slot in the orifice and manually adjust it in small increment, reconnect hose, test it, and adjust again until free flow stops. Is this what the sink test is about. If it's, what is the proper way to do a sink test?

The first part is right. The inline tool allows the adjustment to be made without having to remove and replace the low pressure hose, which speeds up the the process.

I think what you mean by the "sink test" is a check of the cracking pressure. The cracking pressure is the pressure needed to start the flow of gas from the second stage and drives the work of breathing. That is done by immersing the second stage in water diaphragm down until gas flows. Measuring how deep the diaphragm is is the value you are after. Typical values are several inches of water. It is a way to quantify the performance of the regulator. But again it is a "nice to have" in the end. The real test is that you should not have to inhale deeply to start the flow of gas.