SeaRat,

Can you comment on the safety of using PTFE based greases in regulators?

I have heard some concerns about these compounds being used in non-stick cookware and other products. It seems there is a very high probability that whatever lubricant is used in a first stage will have particulates become entrained in the high velocity air stream and therefore be ingested by the diver.

Six2Life,

I just sent his e-mail to the manufacturer:

"

Can you please send me the MSDS for Super-Lube? We have a diver who is about to use this on his regulator as an anti-freeze agent. So it would be helpful to know if there is any potential toxic effect.

"John

"John C. Ratliff, CSP, CIH, MSPH"

I'll have more info after I receive the MSDS.

SeaRat

---------- Post Merged at 07:20 PM ---------- Previous Post was at 12:41 PM ----------

Here are a couple of MSDSs to look at. I'll comment later (I did not receive these from the manufacturer, but from an on-line search).

http://www.skcinc.com/instructions/1792.pdf

http://buysuperlube.com/msds/MSDS_SL_PTFE_Oil.pdf

More after supper.

John

---------- Post Merged at 08:44 PM ---------- Previous Post was at 12:41 PM ----------

Six4Life,

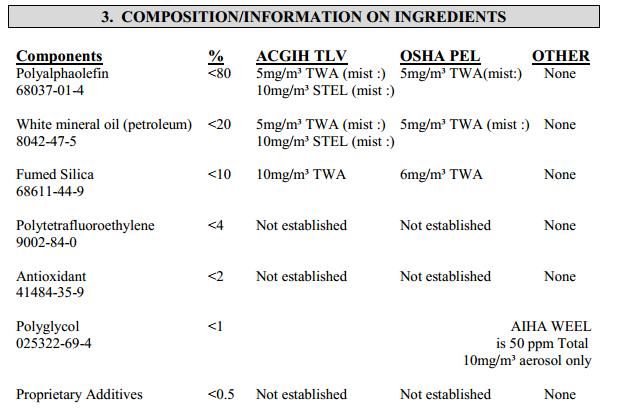

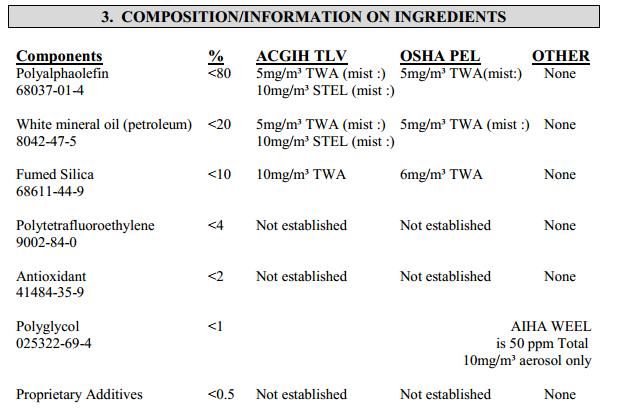

Looking at a product is a rather complex affair. Usually, I won't comment on a product until I have seen the MSDS, and even then only after I know the ingredients (sometimes they are proprietary, and that makes it difficult). In this case, the "Super Lube Oil w/PFTA" MSDS has the information I need to make some decisions. These are difficult to interpert unless a person has a background in industrial hygiene, as there are concepts which are not well understood outside the safety and industrial hygiene professions. Here is the ingredient information from this MSDS:

You will note immediately that there are six ingredients to be concerned about for human exposure. Of these, there are three which have ACGIH TLVs. The American Conference of Governmental Industrial Hygienists (ACGIH) updates their Threshold Limit Values (TLVs) every year according to the information that has been developed through toxicology studies. The TLV is the level of a chemical that the majority of people can be exposed to 8 hours a day, five days a week for a working lifetime without undue effect (the actual definition takes over a page, so this is the shortened version).

So there are three chemicals here which have a TLV,and these are actually for:

"Mineral oil, excluding metal workng fluids (2009)

Pure, highly and severely refined 5 mg/m3

Poorly and mildly refined ---(L)

"(L) Exposures by all routes should be carefully controlled to levels as low as possible."

The term, mg/m3 is the amount, in milligrams that are in a cubic meter of air that is breathed. The term TWA means "Time-Weighted Average" and refers to the amount sampled/unit time as if it were an 8-hour time-weighted average.

Note that PTFE has a "non-established" note. There are many chemicals which have no TLVs, and that does not mean that they present no hazard; just that the toxicology and the need for a TLV has not been established. Also, OSHA PELs (Permissible Exposure Limits) are built on the same definition, but have not been updated since the 1980s due to court action. So we look to other sources. Believe it or not, Wikipedia is one source (but not a primary source) for this information:

http://en.wikipedia.org/wiki/Polytetrafluoroethylene

Basically, from what I can tell the problems with PTFE are only when it is heated and breaks down, and then the off-gasping byproducts can cause flu-like symptoms. I have an acquaintance who was a cook, and he stated that any cookware he had that had PTFEs as a coating would be tossed as soon as the coating was compromised (cut or nicked) because of this effect. However, my wife has had this on her wok, and we have worn it completely off without effects on our health to my knowledge. So this aspect of the Super Lube is not a concern, from my perspective.

The one component I have a concern with is the "fumed silica". Silica is pretty nasty stuff, but apparently this is not the crystalline silica with a very low TLV (0.025 mg/m3). Amorphous silica (which is what apparently "fumed silica" starts as is not as highly toxic as the crystalline silica. That 10% of this mixture is fumed silica is a concern for me if they are in a life-support system such as a demand regulator.

Now, let's talk about the regulator. This is a Conshelf, which is a balanced diaphragm regulator. The diaphragm means that the exterior (water) contact is totally isolated from the interior air flow. If this regulator is equipped with an environmental unit, the material used in the environmental unit (for the first stage) is isolated from the air, and not much of a concern during use. But if this regulator was instead a flow-through piston-style regulator, where the environmental agent (silicone grease, or something experimental) was used, it is possible for the lubricant to get into the air as lubricant can bypass the O-rings and get into the interior air. This would be a problem for this Super Lube w/PTFE.

The TLVs cannot be directly used to discuss hazards in diving, as the amount in the air cannot be sampled or calculated, and all this in dependent on STP (standard temperature and pressure). At incleased pressure, you cannot the TLVs do not hold.

This is not a recommended use of this lubricant:

Potential Health Effects

Inhalation: Not expected to cause respiratory tract irritation during

normal conditions of use.

Skin contact: Repeated or prolonged contact may be irritating to skin.

Eye contact: Contact with eyes may cause irritation.

Ingestion: Not expected under normal conditions of use.

This is why I am very particular about the type of materials I put on my regulator.

John (SeaRat)

John C. Ratliff, CSP, CIH, MSPH