АлександрД

Contributor

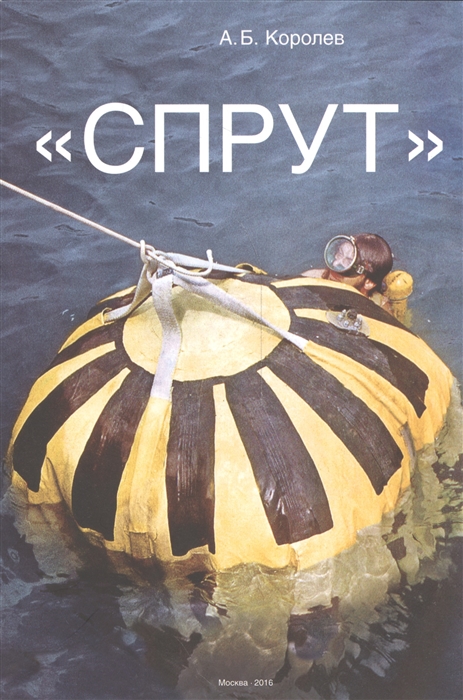

Let me introduce to you one intertesting underwater experiment - building and using underwater inflatable habitat "Спрут" [sprut] ("Kraken"). First underwater installation was made in Jun 14 1967 on the Black Sea.

Late I will publish here some texts (with links), tanslated by google, and some photos from another resources.

I know Alexander Korolev, one of the builders, divers, and sciensists, who work with Спрут.

Those times we discussed with him about first soviet rebreather Epron (first and than 2-5 editions).

You can find some photos on the his FB page here https://www.facebook.com/pg/OceanFrontier/photos/?tab=album&album_id=869367709812989

before his death in 2016, A.Korolev had published his book about this experiment - "Спрут" (Королев А.) - купить книгу с доставкой в интернет-магазине «Читай-город». ISBN: 9785990682078

HYDROSTAT "SPRUT" - UNDERWATER HOUSE PNEUMATIC CONSTRUCTION

This article about Спрут was issued in Спортсмен-подводник magazine #21 (1969).

In July 1967, three athletes, submariners, members of the Moscow city club DOSAAF “Dolphin” Alexander Korolev, Victor Shabalin and William Muravyev set up a Sprut hydrostat designed and manufactured by them in the area of Kara-Dag, where they lived and conducted oceanographic research according to the task All-Union Research Institute of Fisheries and Oceanology.

"Sprut" is the first in the Soviet Union underwater home pneumatic structure. Its shape and stabilization are carried out due to the difference in pressure from inside and outside.

It can be called an underwater aerostat. The basis of the design is a gas-tight sheath made of rubberized fabric. Shell consisting of three layers of tarpaulin and one layer of rubberized aluminized

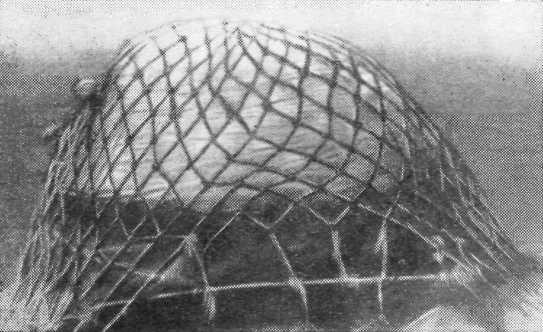

fabric, provides durability and heat insulation. When blowing the upper part of the house takes a spherical shape, the middle - a cylindrical, ending in a flat floor. The outer shell is somewhat smaller than the inner one, which makes it possible to load it as much as possible. Two portholes with a diameter of 300 mm are embedded in the shells. The hydrostat is enclosed in a reinforcing network of hemp rope with a diameter of 10—12 mm. The network cells are assembled below in descents, which then go into four cable slings, securing the hydrostat to the bottom

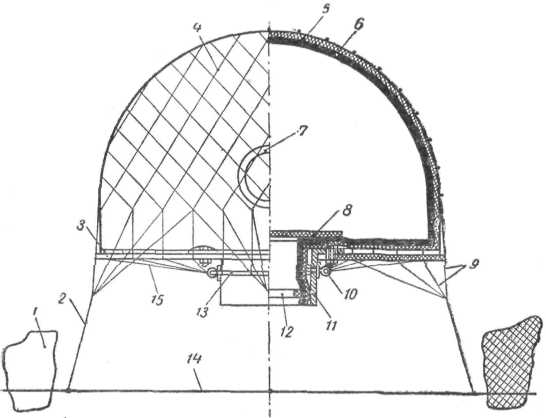

Scheme of the device underwater home:

1 — stone; 2 - lines; 3 - gender; 4 - network; 5 - heat insulating sheath; 6 - gas-tight shell; 7 - porthole; 8 - manhole cover; 9 - house descents; 10 - eye; 11 - hatch; 12 - spacer ring; 13 - floor cable suspension ring; 14 - cable; 15 - floor suspension descents

The reinforcement network reduces the stresses that occur in the shells and is the basis for the suspension of the floor. The floor is a collapsible plywood disk, in the center of which there is a hole with a diameter of 800 mm. A 700 mm high cylinder welded from a thin sheet of stainless steel, which is an access hatch, is fixed in the hole. The edges of the shells are lowered into the hatch and pressed against the outer walls of the spacer ring of rubber hose. Inside the hatch is closed with a plywood cover. The floor is suspended on 63 slopes running from the bottom row of the network cell. Through the hatch passes

air supply hose with a valve at the end, as well as a communication and lighting cable. A constant water level in the hatch is supported by a drain hose, one end of which with a ball valve is in the hatch, the other with a flap valve is brought to the top of the dome.

Valves eliminate the appearance of a water plug in the discharge hose.

In order to keep water in the middle of the hatch level, the house maintains air pressure equal to the pressure at the hatch level. It acts from the inside to all points of the dome. At the level of the top point of the dome, it exceeds the external pressure by the amount of a water column whose height is equal to the height

houses. This excess pressure tends to break the walls of the house. When calculating the pneumatic structures of the ball house, a momentless theory of shells was used, according to which only tangential forces arise in the walls of the house, due to their small thickness.

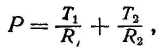

Efforts for shells having the form of bodies of revolution

can be determined from the equation:

where P is the excess pressure;

R 1 and R 2 are the main radii of curvature;

T 1 and T 2 are shear stresses.

For our case, the most suitable form of the dome is a hemisphere. Tangential forces for such a shape are the same at any point in all directions and are equal to T = (PR) / 2, where R is the radius of the sphere.

Modern rubberized nylon-based fabrics have a breaking strength of 3000–2400 kg / m, the worst grades are 300–600 kg / m.

The reinforcing network significantly reduces the forces in the shells, as they are drawn in the cells along radii much smaller than the radius of the dome. Approximately the radius can be taken equal to two diagonals of cells.

Then the breaking forces are T = (P × 2d) / 2 = Pd, where d is the diagonal of the mesh.

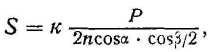

The “Sprut” shell with a hemisphere diameter of 2 m to a diagonal of a 180 mm mesh network experiences a breaking strength of 300 kg, and its breaking strength is 3000 kg / m, that is, it has a tenfold safety margin. The number of cells is calculated based on geometric formulas. The required strength of the network ropes is determined by the formula:

where k - margin of safety;

n is the number of cells in the row;

β is the angle between the sides of the cells;

α is the angle of inclination of the axes of the cells of a given row to the vertical;

Р - house displacement;

S - the force attributable to the rope.

The network with equilateral cells, starting from the bottom row, with the decrease of loops upward, is most simply knitted. For mating acceptable loin knot.

For resistance to tearing and rotting, nylon ropes are best, but they are strongly drawn out.

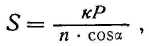

They can be used only after introducing into the network a few steel cable hoops covering the house. Of the other types of most suitable resinous hemp ropes. Descents are made of the same rope. Cable slings are calculated by the formula:

where K is the safety factor;

n - the number of sides of the lines, optimally n = 4;

α is the angle between the sling and the vertical.

When installing a house such as the Sprut, it is necessary to set α = 5 ° —10 ° so that the descents and slings do not squeeze the floor, trying to bend and break it. The maximum angle α in a storm of 6 points at a depth of 10 m did not exceed 30 ° for the Sprut. It is convenient to fasten cables using ordinary clips used in rigging.

Sheathing is done in the same way as a spheroid balloon. Each panel is divided into several trapezoids, which are then cut out according to a pattern and stitched. The seams of the gas-tight shell, in addition, are glued with rubber glue.

Trapezoidal cutting allows to reduce to a minimum fabric stroke.

If the shells are duplicated, it is necessary to center them very precisely before tightening them with windows, otherwise, if you press on, you will get an additional tension of the fabric in the portholes. From this point of view, it is preferable to abandon the second shell, using a more durable fabric or polymeric materials, reinforced with a metal grid.

Established "Sprut" on the ground in the following order.

In the water, the floor was lowered with a reinforcing net, then the descents were attached to dead anchors with cables.

Through the entrance hatch of the sixth they introduced shells and filed them

hose air. At the house roll, the air supply was stopped and the length of the sling was adjusted, then the air supply continued until

full house filling.

For the sake of centering, the shells were tied in place with a string, which was cut during house blowing.

It took four hours to install the house this way.

During a storm when the waves hit, the lower part of our dome

the underwater house pulsed slightly, while the pressure inside the house changed. To regulate pressure, we kept the inlet water level as low as possible using the discharge hose.

"Sprut" withstood a six-point storm without any serious damage.

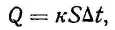

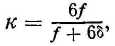

A few words about the life support of aquanauts. As is known, the main issues of human life support under water are heat exchange and air exchange. A person allocates about 100 kilocalories per hour. If the thickness of the walls of the underwater house, taking into account their thermal conductivity, is large enough, then you can not take special measures to heat the house. The thickness of the insulation can be calculated from the heat balance equation

Q + = Q -,

where Q + - heat inside the house;

Q - heat transfer to the environment.

It's obvious that

Q + = nq,

where n is the number of people;

q — heat dissipation of one person.

Q _ - is determined by the formula:

where

f is the thermal conductivity coefficient of the wall material;

δ — wall thickness;

Δ t is the temperature difference inside and outside the house;

S is the surface area of the house.

Late I will publish here some texts (with links), tanslated by google, and some photos from another resources.

I know Alexander Korolev, one of the builders, divers, and sciensists, who work with Спрут.

Those times we discussed with him about first soviet rebreather Epron (first and than 2-5 editions).

You can find some photos on the his FB page here https://www.facebook.com/pg/OceanFrontier/photos/?tab=album&album_id=869367709812989

before his death in 2016, A.Korolev had published his book about this experiment - "Спрут" (Королев А.) - купить книгу с доставкой в интернет-магазине «Читай-город». ISBN: 9785990682078

HYDROSTAT "SPRUT" - UNDERWATER HOUSE PNEUMATIC CONSTRUCTION

This article about Спрут was issued in Спортсмен-подводник magazine #21 (1969).

In July 1967, three athletes, submariners, members of the Moscow city club DOSAAF “Dolphin” Alexander Korolev, Victor Shabalin and William Muravyev set up a Sprut hydrostat designed and manufactured by them in the area of Kara-Dag, where they lived and conducted oceanographic research according to the task All-Union Research Institute of Fisheries and Oceanology.

"Sprut" is the first in the Soviet Union underwater home pneumatic structure. Its shape and stabilization are carried out due to the difference in pressure from inside and outside.

It can be called an underwater aerostat. The basis of the design is a gas-tight sheath made of rubberized fabric. Shell consisting of three layers of tarpaulin and one layer of rubberized aluminized

fabric, provides durability and heat insulation. When blowing the upper part of the house takes a spherical shape, the middle - a cylindrical, ending in a flat floor. The outer shell is somewhat smaller than the inner one, which makes it possible to load it as much as possible. Two portholes with a diameter of 300 mm are embedded in the shells. The hydrostat is enclosed in a reinforcing network of hemp rope with a diameter of 10—12 mm. The network cells are assembled below in descents, which then go into four cable slings, securing the hydrostat to the bottom

Scheme of the device underwater home:

1 — stone; 2 - lines; 3 - gender; 4 - network; 5 - heat insulating sheath; 6 - gas-tight shell; 7 - porthole; 8 - manhole cover; 9 - house descents; 10 - eye; 11 - hatch; 12 - spacer ring; 13 - floor cable suspension ring; 14 - cable; 15 - floor suspension descents

The reinforcement network reduces the stresses that occur in the shells and is the basis for the suspension of the floor. The floor is a collapsible plywood disk, in the center of which there is a hole with a diameter of 800 mm. A 700 mm high cylinder welded from a thin sheet of stainless steel, which is an access hatch, is fixed in the hole. The edges of the shells are lowered into the hatch and pressed against the outer walls of the spacer ring of rubber hose. Inside the hatch is closed with a plywood cover. The floor is suspended on 63 slopes running from the bottom row of the network cell. Through the hatch passes

air supply hose with a valve at the end, as well as a communication and lighting cable. A constant water level in the hatch is supported by a drain hose, one end of which with a ball valve is in the hatch, the other with a flap valve is brought to the top of the dome.

Valves eliminate the appearance of a water plug in the discharge hose.

In order to keep water in the middle of the hatch level, the house maintains air pressure equal to the pressure at the hatch level. It acts from the inside to all points of the dome. At the level of the top point of the dome, it exceeds the external pressure by the amount of a water column whose height is equal to the height

houses. This excess pressure tends to break the walls of the house. When calculating the pneumatic structures of the ball house, a momentless theory of shells was used, according to which only tangential forces arise in the walls of the house, due to their small thickness.

Efforts for shells having the form of bodies of revolution

can be determined from the equation:

where P is the excess pressure;

R 1 and R 2 are the main radii of curvature;

T 1 and T 2 are shear stresses.

For our case, the most suitable form of the dome is a hemisphere. Tangential forces for such a shape are the same at any point in all directions and are equal to T = (PR) / 2, where R is the radius of the sphere.

Modern rubberized nylon-based fabrics have a breaking strength of 3000–2400 kg / m, the worst grades are 300–600 kg / m.

The reinforcing network significantly reduces the forces in the shells, as they are drawn in the cells along radii much smaller than the radius of the dome. Approximately the radius can be taken equal to two diagonals of cells.

Then the breaking forces are T = (P × 2d) / 2 = Pd, where d is the diagonal of the mesh.

The “Sprut” shell with a hemisphere diameter of 2 m to a diagonal of a 180 mm mesh network experiences a breaking strength of 300 kg, and its breaking strength is 3000 kg / m, that is, it has a tenfold safety margin. The number of cells is calculated based on geometric formulas. The required strength of the network ropes is determined by the formula:

where k - margin of safety;

n is the number of cells in the row;

β is the angle between the sides of the cells;

α is the angle of inclination of the axes of the cells of a given row to the vertical;

Р - house displacement;

S - the force attributable to the rope.

The network with equilateral cells, starting from the bottom row, with the decrease of loops upward, is most simply knitted. For mating acceptable loin knot.

For resistance to tearing and rotting, nylon ropes are best, but they are strongly drawn out.

They can be used only after introducing into the network a few steel cable hoops covering the house. Of the other types of most suitable resinous hemp ropes. Descents are made of the same rope. Cable slings are calculated by the formula:

where K is the safety factor;

n - the number of sides of the lines, optimally n = 4;

α is the angle between the sling and the vertical.

When installing a house such as the Sprut, it is necessary to set α = 5 ° —10 ° so that the descents and slings do not squeeze the floor, trying to bend and break it. The maximum angle α in a storm of 6 points at a depth of 10 m did not exceed 30 ° for the Sprut. It is convenient to fasten cables using ordinary clips used in rigging.

Sheathing is done in the same way as a spheroid balloon. Each panel is divided into several trapezoids, which are then cut out according to a pattern and stitched. The seams of the gas-tight shell, in addition, are glued with rubber glue.

Trapezoidal cutting allows to reduce to a minimum fabric stroke.

If the shells are duplicated, it is necessary to center them very precisely before tightening them with windows, otherwise, if you press on, you will get an additional tension of the fabric in the portholes. From this point of view, it is preferable to abandon the second shell, using a more durable fabric or polymeric materials, reinforced with a metal grid.

Established "Sprut" on the ground in the following order.

In the water, the floor was lowered with a reinforcing net, then the descents were attached to dead anchors with cables.

Through the entrance hatch of the sixth they introduced shells and filed them

hose air. At the house roll, the air supply was stopped and the length of the sling was adjusted, then the air supply continued until

full house filling.

For the sake of centering, the shells were tied in place with a string, which was cut during house blowing.

It took four hours to install the house this way.

During a storm when the waves hit, the lower part of our dome

the underwater house pulsed slightly, while the pressure inside the house changed. To regulate pressure, we kept the inlet water level as low as possible using the discharge hose.

"Sprut" withstood a six-point storm without any serious damage.

A few words about the life support of aquanauts. As is known, the main issues of human life support under water are heat exchange and air exchange. A person allocates about 100 kilocalories per hour. If the thickness of the walls of the underwater house, taking into account their thermal conductivity, is large enough, then you can not take special measures to heat the house. The thickness of the insulation can be calculated from the heat balance equation

Q + = Q -,

where Q + - heat inside the house;

Q - heat transfer to the environment.

It's obvious that

Q + = nq,

where n is the number of people;

q — heat dissipation of one person.

Q _ - is determined by the formula:

where

f is the thermal conductivity coefficient of the wall material;

δ — wall thickness;

Δ t is the temperature difference inside and outside the house;

S is the surface area of the house.