So let's parse this out a bit for those reading along...

So Poseidon regs flood like Atomic when depressurized?

The Jetstream and Xstream being upstream require intermediate pressure to seal. If the valve is off then they can flood but they flood back from the second stage which is different than atomic.

If, properly oxygen cleaned (despite not being oxygen certified), we have a regulator with a risk/reward equation that many have chosen to use for technical diving. They have judged that they are not likely to have an ignition fire since, 1) it did not ignite on initial pressurization and more importantly, 2) their technique convinces them that they are not going to introduce hydrocarbons into the gas flow pathway over the repeated tank refills and disconnections/reconnections over the service interval.

The next question is one that

@Tracy and

@tbone1004 have focused on - the risk of depressurization and first stage flooding. For an open ocean technical diver like me, being able to see my deco gas bottle (and any bubbles coming from it) makes leaving the valve pressurized less of a risk. That the old style Jetstream OPV in the hose connection to the second stage is more susceptible to leaking when bumped is also true, as pointed out by

@Tracy . Some of my hoses will vent with a little as 0.5mm pull when pressurized. For me, that's not a deal breaker with a sidemounted bottle under my arm. But like

@tbone1004 , I won't leave a "charged but off" bottle in a wreck corridor for later retrieval if it has a Jetstream on it. Nor will I leave an Atomic in the same situation.

The Jetstream, as is continuously pointed out, is sort of an upstream valve. Actually, only the servo is upstream, while the bell-shaped main valve is a bit of a hybrid. The point is, when pressurized, any valve will remain closed.

If a "charged but off" downstream valve like an R295 or C350 or Cyklon is bumped, the valve seat still wants to stay stuck to the orifice knife edge, because like a toilet bowl flapper valve, it is now pushed closed by the fact that ambient seawater pressure may be greater than the pressure inside the LP hose. Plus, there's that heavy spring keeping the valve seat flat against the orifice.

If a standard barrel style balanced second like a G250 or Apeks TX50 depressurizes, the same thing happens. The valve wants to stay closed because slightly higher seawater pressure is pushing the valve closed. Now however, the spring assisting the closure is much lighter, marginally increasing the risk that sea water can seep up the hose and reach the first stage. Actually this whole thing is probably not true unless you carry the unpressurized rig deeper in the water column. At the depth it was depressurized, hose pressure will be at ambient, with no net gradient toward the first stage unless the second is higher.

With an Atomic however, there is a small wave spring behind the orifice, which is free-floating. Under pressure, the IP pushes the larger diameter of the orifice against the seat, sealing the valve.

When depressurized, the wave spring lifts the orifice from the seat, preventing indentation while in storage. However, this opens the valve, allowing the ambient sea water access to the hose.

There's still an increasing pressure gradient as seawater rises in the hose, because the tank connection should create a cap acting as a dam against rising sea water, unless the second stage is above the first, in which case water just runs downhill.

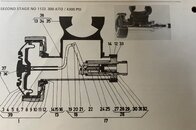

For the Jetstream, the anatomy is a little different. There is a bell-shaped seat which is pressed against the valve outflow holes by the pressure inside the servo mechanism. But if bumped, depressurization allows the bell to collapse, allowing seawater into the hose.

(Fantastic drawing courtesy of

@Fibonacci)

Again, flooding won't occur unless the second is higher than the first, or the tank connection loosens when depressurized.

In summary, I think the choice revolves more around second stage than first, if you accept that divers have been successfully oxygen cleaning and diving "uncertified" regs for a long, long time.

My 2 cents. Like Tom said,

Leave the valve open the entire time, or use a different [second stage] regulator.