Let's remember that as humans, we all forget things, make simple mistakes and quite often our understanding changes with education and experience. How often do we catch a spelling or grammatical error in a published manual or book? By the Cyrillic in his name, it's obvious that English is a second language for the author you cited. It's not unusual for a non-native speaker to get a translation wrong. I am kind of amazed that there has been so much written on SB about this topic. Akimbo's piece is far better than mine and I'm sure Alexander's holds up to scrutiny as well.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

O-Rings 101, Understand the seal-eology

- Thread starter The Chairman

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

I've never seen UNF used in describing pipe threads. UNF is equivalent to NF and UNC is equivalent to NC.

Perhaps this?

UNC and UNF - Unified Inch Screw Threads

(screw/bolt)

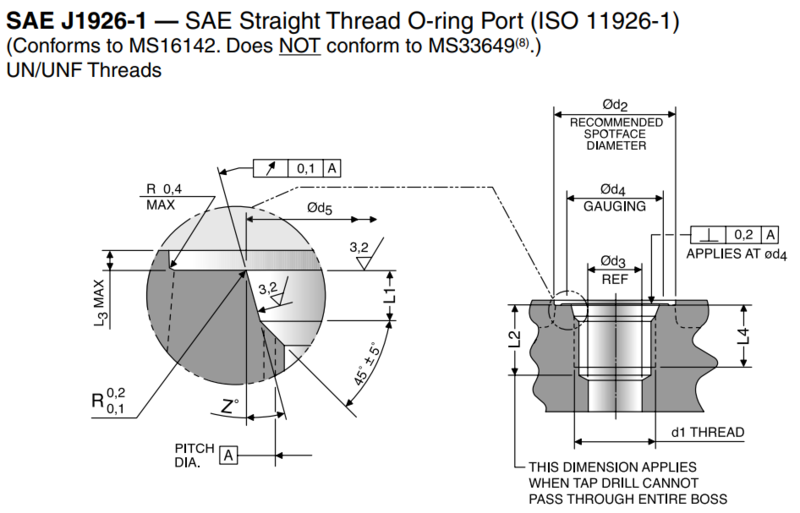

Technically, LP and HP ports on first stage Scuba regulators meet the SAE J1926 standard for straight thread O-ring sealed ports. As you can see from this link, SAE dash size 3 or 3/16" has a 3/8-24 UNF-2B thread and the -4 or 1/4" has a 7/16-20 UNF-2B thread. The -3 is used for the LP boss and the -4 is used for the HP.

Fittings compatible with these ports are more than just a straight thread with a hex of pan-head. The threads require a specific undercut at the top of the threads below the head to support the O-ring. Fortunately, manufacturers of tube fittings have a variety of adapters that also meet this standard -- which is handy for DIYers that want to adapt first stages for special purposes.

Cutting Tools for the complex surfaces that accepts the O-ring can be purchased from most machine shop suppliers. They are fairly expensive and require a very rigid machine tool to achieve the proper finishes. I tried it on Brass once using a good quality drill press and got way too much chatter. These cutters are intended for vertical mills or equal. Example: SAE J1926 Porting Tools, MSC Direct

You can improvise a first stage adapter that can be held by a shop vise using a long 3/8-24 UNF or 7/16-20 UNF bolt fitted with a small OD protective hard plastic washer and a lock nut. Commercially made units are better but this trick can work in a pinch.

Fittings compatible with these ports are more than just a straight thread with a hex of pan-head. The threads require a specific undercut at the top of the threads below the head to support the O-ring. Fortunately, manufacturers of tube fittings have a variety of adapters that also meet this standard -- which is handy for DIYers that want to adapt first stages for special purposes.

Cutting Tools for the complex surfaces that accepts the O-ring can be purchased from most machine shop suppliers. They are fairly expensive and require a very rigid machine tool to achieve the proper finishes. I tried it on Brass once using a good quality drill press and got way too much chatter. These cutters are intended for vertical mills or equal. Example: SAE J1926 Porting Tools, MSC Direct

You can improvise a first stage adapter that can be held by a shop vise using a long 3/8-24 UNF or 7/16-20 UNF bolt fitted with a small OD protective hard plastic washer and a lock nut. Commercially made units are better but this trick can work in a pinch.

Technically, LP and HP ports on first stage Scuba regulators meet the SAE J1926 standard for straight thread O-ring sealed ports. As you can see from this link, SAE dash size 3 or 3/16" has a 3/8-24 UNF-2B thread and the -4 or 1/4" has a 7/16-20 UNF-2B thread. The -3 is used for the LP boss and the -4 is used for the HP.

So, LP and HP ports are 3/8 and 7/16 UNF threads and not NPS.

So, LP and HP ports are 3/8 and 7/16 UNF threads and not NPS.

I have checked my old copy of the Machinery's Handbook and find several and confusing descriptions of NPS. It is possible that there are some specs for NPS that happen to have compatible threads to 3/8 and 7/16 UNF. In any case, it is unlikely that a relief under the head of plugs would exist since the standard pre-existed significant availability of O-rings.

It may be like DIN. You would think that it would be a metric thread instead of BSP. Standards tend to follow "common use" at the time they developed instead of starting with a clean slate and a round-table of engineers.

For most readers that have no idea what NPS is, it is part of the American National Standard Pipe Thread specifications. NPS stands for National Pipe Straight. For all practical purposes, it is rarely used for pressure piping, at least in the last 50+ years. NPT stands for National Pipe Taper and is in common use around the world.

O-ring Picks. These come in a variety of materials and shapes. Brass is soft and less likely to damage sealing surfaces. Stainless steel is my choice because I can get them very thin and sharp allowing me to slip it beneath an o-ring.

Being an ex U.S Navy submariner who subsequently worked for a Naval Shipyard for 20 years, I must say I died a little inside when I read this.

These are brass, super pointy and work extremely well. The kit even comes with a blunted one to help manipulate new o-rings into those tougher to get in to grooves without puncturing them. Takes away all the worries of steel picks!

Scuba Diving Dive Brass O-Ring Pick Set Tool - 3pcs

Last edited:

I may be wrong but I think that reg port plugs are not straight pipe thread.I believe the use of UNF to be in error there. If you read the Wiki page on NPT, you won't find a mention of UNC or UNF: National pipe thread - Wikipedia

Yes, you are wrong. Good catch.I may be wrong but I think that reg port plugs are not straight pipe thread.

Pete, I was trying to give you a graceful way out.Yes, you are wrong. Good catch.

Here is a chart of pipe thread sizes and thread pitches. Which ones match UNF 3/8-24 and 7/16-20?

https://static1.squarespace.com/sta...1500403835700/National+Pipe+Thread+Chart+.pdf

Fun fact: all Scuba regulators, even those from overseas, use National Pipe straight threads for the port plugs. Most the pipes in your house have the older tapered threads. How do you know? If it has an o-ring, it's a straight pipe thread. If it's being sealed with teflon tape or pipe dope, it's tapered and very rare nowadays in Scuba. The common sizes (as I remember them)

Some of the old, realy old, poseidon regulators use metric threads.

And i think today the most use.

7/16" for HP ports

3/8" for LP ports

But some have one 1/2" port for primary regulator.

Some older regulators have 3/8" for all ports.

Similar threads

- Replies

- 3

- Views

- 429