- Messages

- 8,632

- Reaction score

- 7,343

- # of dives

- 2500 - 4999

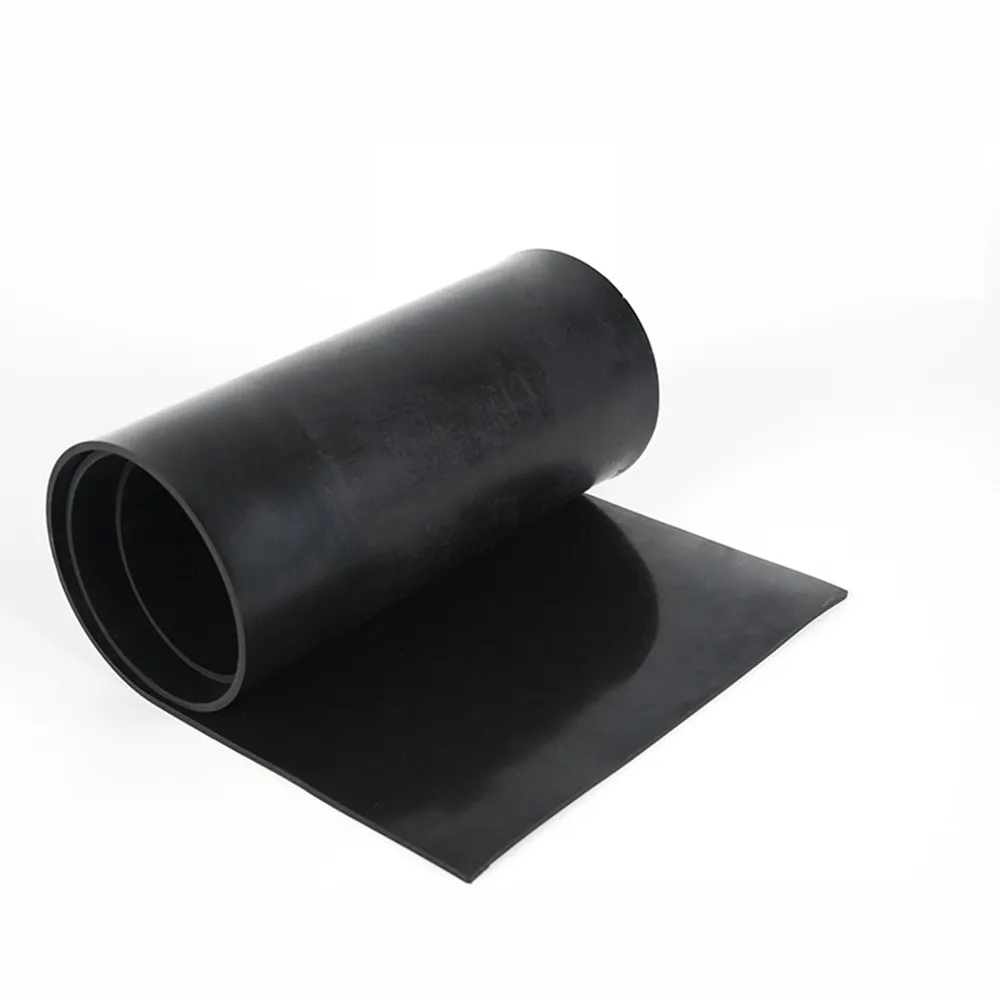

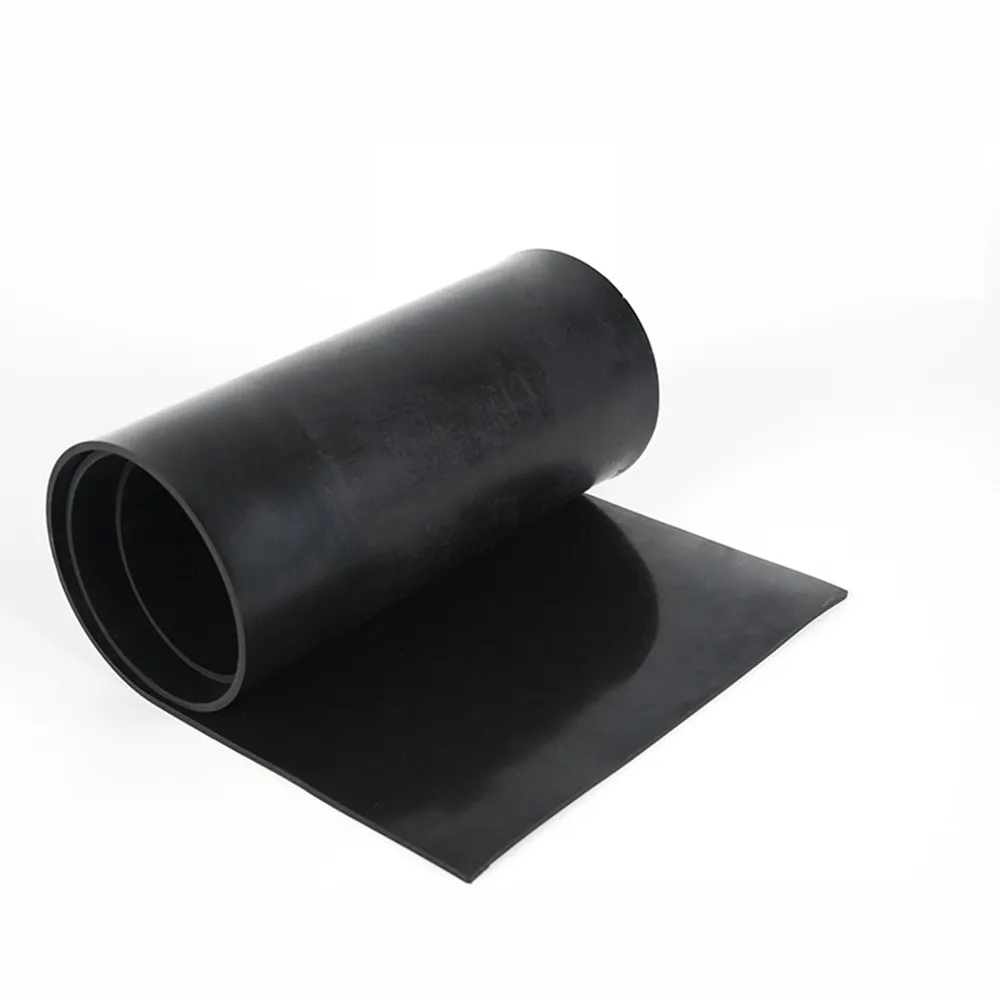

Mate go buy a punch and some rubber or just aliexpress or **** it

www.aliexpress.com

www.aliexpress.com

and get punching

production technique

Fluor folie Aflas Gummi platte fpm Viton folie Fluor kautschuk öl Hitze Korrosion Säure-Base-Beständigkeit fkm Gummi platte - AliExpress 13

Smarter Shopping, Better Living! Aliexpress.com

https://www.****.com/ul/kuiper/un9....Gvt6vD4AX28L84myFBwOUmWTVvX-_RNAaAuxNEALw_wcB

and get punching