I liked his idea but I was thinking that it wouldn't be easy to keep water out of the engine.

For the exhaust he could attach something akin to a 2nd stage as well. I think his initial design was too complicated and it won't work. A regulator type exhaust chamber would keep it water free enough, and whatever water does get in would probably turn to steam from the heat.... and he could also vent it straight into the water provided the exhaust valve was mounted deeper than the exhaust outlet from the engine. The problem then becomes thinking in 3 dimensions..... what happens if you go upside down with it?

I don't know how much air it would use but his idea of using a regulator to deliver air on demand certainly wasn't bad and I think it's worth doing some calculations to see if it's feasible.

The big question becomes this: how water tight can the inlet connection be? Because even a small amount of water in the engine will turn it off. This will need to be very robust and I'm not at all convinced that it would work without a lot of modifications. Also lawn mower engines have moving parts that will be in direct contact with the water, which isn't going to make it work better....

What might work better is to make a dry chamber out of a water tight box. The box would house the entire engine so even the moving parts don't contact the water. The box could be kept at ambient pressure with a scuba regulator, which would avoid all of the problems with heat melting the plastic bits and the engine could be supplied with any air it needed by the regulator. Exhaust would still have to go via an intermediate chamber into the water. We once helped a guy design a dry box for a hobby submarine what worked exactly like this, although his sub used an electric motor.

R..

Your last paragraph is exactly what I meant by a "sealed chamber for the engine". I think using a reg for air input is a really good idea, I just think he's going to find he needs a lot more airflow than he expects. Combustion actually takes quite a lot of air. Yes, it can be done, (we've had diesel submarines for what--70 years and steam subs before that) but I don't think you'd get any real gains in efficiency or ease of use/design.

Hence my statement that the NRE (non-recurring engineering for non-engineer types) involved would probably put the effort far too expensive compared to using existing electric motors. It works really good for large scale submersibles, but for small "recreational" single person vehicles, I don't think it would be cost effective.

It would be a very interesting problem, though, and certainly fun to design/build, if that's the impetus for this project.

---------- Post Merged at 03:28 PM ---------- Previous Post was at 03:15 PM ----------

Ok so i found some great 55lbs trolling motors for about $370.

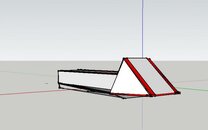

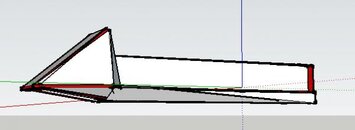

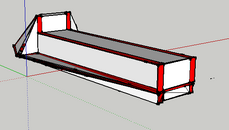

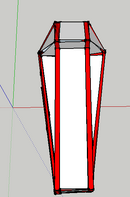

For the hull: Could i build a frame our of wood (maybe with some metal reinforcements) and then just fiberglass over the inside and out. Leaving the wood completely sealed? Could i even use polyurethane foam in some places (curvy bits because its exceptionally sand-able)? Would water have any chance of getting in if i really covered everything? I was thinking that maybe a flooded hull with sealed off electronics might be beneficial. I know it would add alot of mass, but I wouldn't need counterweights, so it wouldn't weigh a ton out of water.

I will see if i can scan some drawings in soon to see what you guys think.

Stitch and glue kayaks are basically a sandwich of 3-6mm plywood between layers of fiberglass (sometimes only the outside is glassed) that are literally "sewn" together at the edges of the wood and then "glued" to fill in the seams. They are very good at keeping water in or out if the builder is good at wetting out the glass and filling the weave properly. You could feasibly build a hull with just this type of build and not need a "frame" per se.

Foam could work for some parts but joining the foam with any non-foam pieces can be a bit of a pain. There are glues that will definitely work, but I wouldn't trust the foam as a structural component. Maybe a nose-cone or use it as bulkheads between chambers but nothing truly structural. It does sand well, though, and would reduce overall weight.

Potting the electronics would definitely be beneficial but makes it impossible to repair anything in the future. I'd make sure you test everything very well before doing that or just forgo it and consider "coating" individual components without potting everything.

As for your trolling motors, while weight may not be an issue in the water, requiring a crane to get the thing from boat to water might be a little too much to ask for in non-scientific environments. There are quite a few motors out there designed as "axle motors" for bike and electric motorcycle wheels that should be significantly lighter that would work well for pushing a screw. I suspect you could get quite a bit of torque from them and get a good in-water speed, with some careful selection of components.