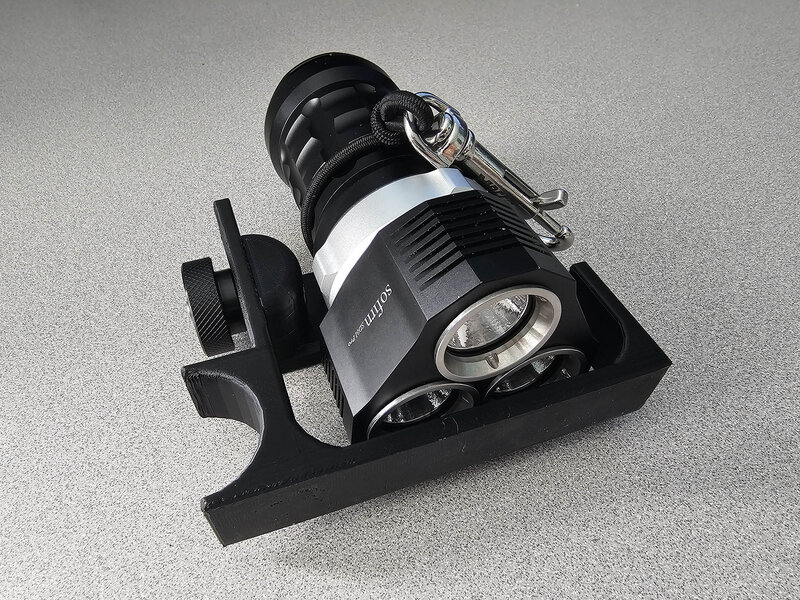

Lots of great ideas on this board guys! Here's my small contribution. A Sofirn SD01 torch is a pretty good buy for $85, with excellent brightness and a really long run time. Its also fairly heavy for a handheld and its balance is a little awkward. Mounting it to an off-the-shelf goodman makes it quite backheavy and too close to the wrist. I wanted to see if I could gin up a goodman that located center mass right over the handle, making this light a little more wieldy with plenty of room to rotate the magnetic switch. Here's some pics, and down below I'll share some details as well as links drawing and files in case you want to print one or remix it for your own taste. This is 3d printed out of ABS with 100% infill and uses standard 5/16-18 hardware:

TinkerCAD Drawing Link

Thingiverse .STL files

Other than the two 3D prints, this uses:

5/16-18 x 1.5" stainless flat head cap screw

5/16-18 stainless nylon locknut

5/16-18 delrin speed nut

some 4mm bungie and a bolt snap

Thoughts? Suggestions for improvement?

TinkerCAD Drawing Link

Thingiverse .STL files

Other than the two 3D prints, this uses:

5/16-18 x 1.5" stainless flat head cap screw

5/16-18 stainless nylon locknut

5/16-18 delrin speed nut

some 4mm bungie and a bolt snap

Thoughts? Suggestions for improvement?