You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Force Fin Designs

- Thread starter Bob Evans

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Bob Evans

Contributor

When I look out that window, I think how close it all was.....https://forcefin.com/engineers/

Bob Evans

Contributor

Wow, we just got another price increase on our brass bushings. $ 5.00 per part. $ 20.00 now and another price increase from our Force Fin Plant. It looks like we are going to be priced out of the market. Our website is also been attacked by hackers in Russia, China, and India. I had to remove the Waving American flag due to AI pegging us a MEGA—crazy times with a significant drop in sales. But don't worry, we have backup inventory and will weather up coming costs.

Bob Evans

Contributor

Bob Evans

Contributor

I looked back at over 25 years of making all the Force Fin tooling. Amazing

Bob Evans

Contributor

Creativity drives a desire to see things better. A sense of caring for all. Divine destiny to save human race from its own destructive actions. I've memories of a large arena, with thousands around tasked with balancing life here on this planet. We were weighing very heavy on the side of dump this round on Earth. Hope is gone. I step up and say, I will go back to turn the tide with others who have a dream of heaven on earth. I heard a "Good luck" and the debate continued as I left. An interesting interview with Polly Frost. It gives you an inside view of why Force Fins. Polly Frost - Blog - INTERVIEW WITH BOB EVANS

Bob Evans

Contributor

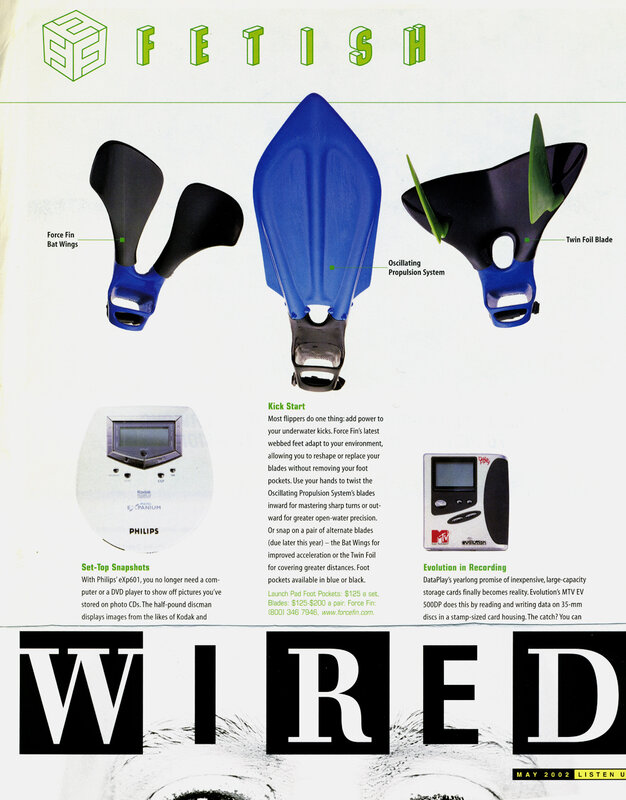

I found this image of the future of Split Fins. I used the SD-1 adjustable foot pocket and noticed

how wide I had to make the split area in order to move the water flow between the foiled blades. Force Fin These models were made over 15 years ago and will be selling off extra pairs at a high price since we do not plan to produce in the near future.

how wide I had to make the split area in order to move the water flow between the foiled blades. Force Fin These models were made over 15 years ago and will be selling off extra pairs at a high price since we do not plan to produce in the near future.

Bob Evans

Contributor

They seem to be super expensive. But the OPS kit is one of a kind. We pay a fortune for underwater camera systems. My camera system, way back in the early 80s, cost around five grand. Most fins manufactured today cost less than $20.00 to make. Our manufacturing cost for Force Fins is now at around $ 140.00 per pair. Our super High-Performance poly urethane sets the highest standards in the dive industry. This pair of OPS cost was somewhere around $40,000. So, here you go if you want something super rare and will never hit the market. Force Fin OPS | eBay

Bob Evans

Contributor

I had been getting into shapes and took a minute to think back when I realized my Jet Fins made no sense regarding water flow. I purchased a pair (1966) at Dive N Surf in Redondo Beach. The Meistrell Brothers Bob and Bill have given me a job filling scuba tanks. Their Beach shop was one of the first to offer diving equipment and repair. Diving Jet Fins for many thousands of dives I had the experience to understand how they work, nothing like a Jet. Force Fins were developed with internal ribbing. The clean edges allowed water to flow easily, with Eddie sheading. A small shape with, a V to directs the water flow to the tips. The Jet Fin is so perfect for Frog Kicking since it kind of locks you into the kick, whereas the Force Fin cuts quickly and you need to learn how to control this action. Big Thick Ribs came out of manufacturing rubber at the time. I had a chance to view ScubaPro's rubber plant in Mexico. Making Jet's fins was not an easy job, like what I saw Mares doing in Italy. Plastic fins are made in two minutes and dropped into a box for $16.00 per pair. Too much hand labor with Rubber and the same for us. Force Fin heat treating takes 16 hours at 250 degrees and trimming and straps. Polyurethane allowed me to change Fins Designs like no other fins as of today. Have a Great Fourth of July> Remember our great American heroes. God Bless America.

Bob Evans

Contributor

I found this image today that shows how I used internal ribbing within two sheets of Stevens Urethane film. Susanne was able to sew a ribbing form and then we pumped into this space Polyurethane to cast solid. I was able to create different fin layouts within a week. This was back in 2000. This pair of my Split Fin designs had this ribbing to control the split opening rate while kicking. Adjustable foot pocket that allowed the fins to float. On your foot, they held neutral. The first " Split Fin"

Foil Force used a curved shape to direct water flow. Foil Force Fin - Force Fins | Worlds Finest Fins for Swimming, Diving, Bellyboating

Foil Force used a curved shape to direct water flow. Foil Force Fin - Force Fins | Worlds Finest Fins for Swimming, Diving, Bellyboating

Similar threads

- Replies

- 24

- Views

- 2,077

- Replies

- 3

- Views

- 555