Any news?!I'm trying to get WOB and cracking specs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D420! How about that?

- Thread starter axxel57

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

- Messages

- 17,699

- Reaction score

- 9,970

- Location

- Somewhere between here and there

- # of dives

- 2500 - 4999

Any news?!

Was told manual supposed to be released January.

sbijou

Contributor

Part of the beauty of the D420 starting with its lineage in the Pilot, was it never needed a cracking effort adjustment. Once set by the technician to your preference, the breathing is quite different than a conventional second stage. It is more relaxed and effortless.

Plus based on the case geometry and vertical mechanism, how would a cracking effort knob be

placed? Perhaps someone with more technical knowledge assist?

Plus based on the case geometry and vertical mechanism, how would a cracking effort knob be

placed? Perhaps someone with more technical knowledge assist?

@sbijou is right. A cracking adjustment is one of those diver add-ons that is more bling than practical. Think about it...when would you ever want to increase your cracking effort? I mean, there are divers who do like their regs stiff, and there are those who (erroneously) believe it helps them use less gas, but for most of us, the beauty of the D400's design was the ability to tune below mfr spec and breathe at 0.6"!! It is glorious.

With the D 400, the lack of a diver-adjustable Venturi meant that it had to have a dive/pre-dive switch in order to minimize freeflow if it got banged around at the surface or on surf entry. That switch controlled a spring which basically held the lever forward until you exerted 2-3 inches of suck to trigger. It's an inelegant way of controlling freeflow.

Changing Venturi adjustment itself could only be done by reaching inside the mouthpiece with a tool, and clicking the collar gate a few clicks to one side or another to disrupt flow. Not possible during a dive, lol!

Much better is the new design: it allows cracking effort to stay as low as possible, while using disruption of Venturi flow to prevent the reg valve from staying open if it is triggered with a bang on the diaphragm.

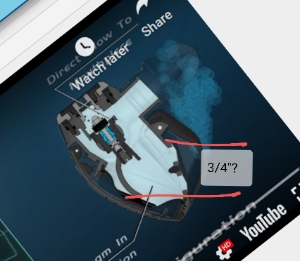

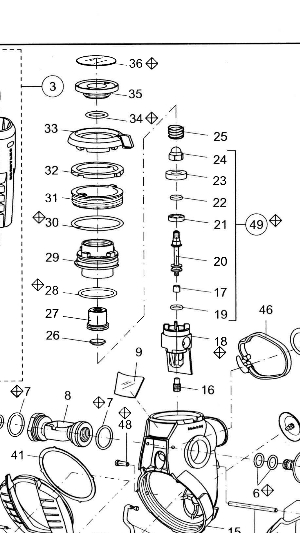

That ring on top is connected to part #29 (flow vane), which acts like the collar in the pic above.

At great depth, when increased air density significantly increases Venturi effects, any tendency for the reg to stay open on inhalation can be corrected by a slight turn of the Venturi knob on top, rather than increasing cracking effort. After all, for WOB concerns, with high gas density the last thing you want to do is increase the effort it takes to also trigger the valve.

As for cracking effort itself, I think the case geometry for this reg is not quite as good as the original D400 because with that design the diaphragm and exhaust valves were coaxial.

However the engineers have compensated for that flaw by putting the exhaust valve right behind the diaphragm and at the same level in normal diving position. This enabled them to put a larger exhalation valve in there, improving the work of breathing, while minimizing the impact on case geometry. I'm going to guess that we should be able to tune this as low as 0.75". We'll know more at the unboxing. In any case, with the exhalation valve above the center of the diaphragm in normal diving position, exhalation WOB is decreased, compared with the original design. That's the advantage of the S600 and classic G250 designs: when looking down slightly, the higher exhalation valve position assists exhalation, at the cost of increased cracking effort compared to the D400. Thus, the sum of both inhalation and exhalation WOB favored the S600 design. Now, with a large exhalation valve, decreasing exhalation effort coupled with a low cracking effort for a center-balanced poppet should favor the D420. We'll see.

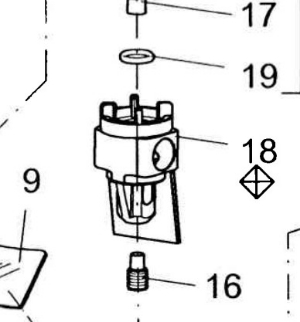

As for the last question, regarding where you would put a cracking adjustment if you wanted to? It would be on top, in the middle of that Venturi adjustment ring. If you look at the schematic attached,

the spring that controls pressure on the poppet is part # 25, and would increase cracking effort if you screwed in something connected to part #27, the adjustment screw tuned by the technician. The beauty of a center-balanced poppet is that it is so stable and lightweight that it stays in adjustment for a very long time. I have D-400s sitting on the bench that haven't been dived in two years and still crack at 0.8". Any diver adjustment that increased the pressure on spring #25 would have to be very subtle, however. The difference between 0.6" and 1.3" cracking effort is less than a half turn on a D-400.

With the D 400, the lack of a diver-adjustable Venturi meant that it had to have a dive/pre-dive switch in order to minimize freeflow if it got banged around at the surface or on surf entry. That switch controlled a spring which basically held the lever forward until you exerted 2-3 inches of suck to trigger. It's an inelegant way of controlling freeflow.

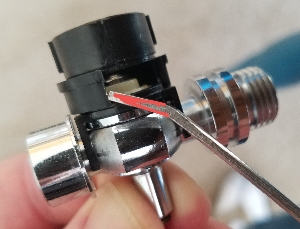

Changing Venturi adjustment itself could only be done by reaching inside the mouthpiece with a tool, and clicking the collar gate a few clicks to one side or another to disrupt flow. Not possible during a dive, lol!

Much better is the new design: it allows cracking effort to stay as low as possible, while using disruption of Venturi flow to prevent the reg valve from staying open if it is triggered with a bang on the diaphragm.

That ring on top is connected to part #29 (flow vane), which acts like the collar in the pic above.

At great depth, when increased air density significantly increases Venturi effects, any tendency for the reg to stay open on inhalation can be corrected by a slight turn of the Venturi knob on top, rather than increasing cracking effort. After all, for WOB concerns, with high gas density the last thing you want to do is increase the effort it takes to also trigger the valve.

As for cracking effort itself, I think the case geometry for this reg is not quite as good as the original D400 because with that design the diaphragm and exhaust valves were coaxial.

However the engineers have compensated for that flaw by putting the exhaust valve right behind the diaphragm and at the same level in normal diving position. This enabled them to put a larger exhalation valve in there, improving the work of breathing, while minimizing the impact on case geometry. I'm going to guess that we should be able to tune this as low as 0.75". We'll know more at the unboxing. In any case, with the exhalation valve above the center of the diaphragm in normal diving position, exhalation WOB is decreased, compared with the original design. That's the advantage of the S600 and classic G250 designs: when looking down slightly, the higher exhalation valve position assists exhalation, at the cost of increased cracking effort compared to the D400. Thus, the sum of both inhalation and exhalation WOB favored the S600 design. Now, with a large exhalation valve, decreasing exhalation effort coupled with a low cracking effort for a center-balanced poppet should favor the D420. We'll see.

As for the last question, regarding where you would put a cracking adjustment if you wanted to? It would be on top, in the middle of that Venturi adjustment ring. If you look at the schematic attached,

the spring that controls pressure on the poppet is part # 25, and would increase cracking effort if you screwed in something connected to part #27, the adjustment screw tuned by the technician. The beauty of a center-balanced poppet is that it is so stable and lightweight that it stays in adjustment for a very long time. I have D-400s sitting on the bench that haven't been dived in two years and still crack at 0.8". Any diver adjustment that increased the pressure on spring #25 would have to be very subtle, however. The difference between 0.6" and 1.3" cracking effort is less than a half turn on a D-400.

Attachments

Whoa!

Just noticed something else!

Scubapro's cure for ham-fisted technicians!

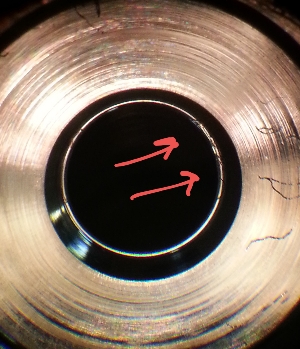

One of the delicate things about the old beautiful metal orifice was how little it took to ding the knife edge. Even putting the metal stem poppet back in roughly could scrape that sealing edge.

Well, as I was looking at the schematics for the fiftieth time (I got nothing else to do until Santa Claus comes), I noticed that the orifice had this odd little deflector hanging off the back.

And I thought to myself, they are probably making a plastic orifice after all! That's too odd a molding for a metal part.

And that's when I noticed the big thing:

The orifice is a biennial service replaceable part!!! (That's what the diamond means) A new knife edge will come in every kit!

So now I can't wait to see what it's made of. Looks too complicated to be Delrin. That's a good thing, because the replaceable Delrin orifice in the very last model D400 sucked, compared with the metal orifice. If it's hard black plastic like the cage in the pic above, we should be able to get a nice sharp edge. That seems to be what the video is showing:

The suspense is killing me!

Just noticed something else!

Scubapro's cure for ham-fisted technicians!

One of the delicate things about the old beautiful metal orifice was how little it took to ding the knife edge. Even putting the metal stem poppet back in roughly could scrape that sealing edge.

Well, as I was looking at the schematics for the fiftieth time (I got nothing else to do until Santa Claus comes), I noticed that the orifice had this odd little deflector hanging off the back.

And I thought to myself, they are probably making a plastic orifice after all! That's too odd a molding for a metal part.

And that's when I noticed the big thing:

The orifice is a biennial service replaceable part!!! (That's what the diamond means) A new knife edge will come in every kit!

So now I can't wait to see what it's made of. Looks too complicated to be Delrin. That's a good thing, because the replaceable Delrin orifice in the very last model D400 sucked, compared with the metal orifice. If it's hard black plastic like the cage in the pic above, we should be able to get a nice sharp edge. That seems to be what the video is showing:

The suspense is killing me!

Whoa!

Just noticed something else!

Scubapro's cure for ham-fisted technicians!

One of the delicate things about the old beautiful metal orifice was how little it took to ding the knife edge. Even putting the metal stem poppet back in roughly could scrape that sealing edge.

View attachment 555514

Well, as I was looking at the schematics for the fiftieth time (I got nothing else to do until Santa Claus comes), I noticed that the orifice had this odd little deflector hanging off the back.

View attachment 555515

And I thought to myself, they are probably making a plastic orifice after all! That's too odd a molding for a metal part.

And that's when I noticed the big thing:

View attachment 555517

The orifice is a biennial service replaceable part!!! (That's what the diamond means) It'll come in every kit!

So now I can't wait to see what it's made of. Looks too complicated to be Delrin. That's a good thing, because the replaceable Delrin orifice in the very last model D400 sucked, compared with the metal orifice. If it's hard black plastic like the cage in the pic above, we should be able to get a nice sharp edge.

The suspense is killing me!

I am starting to get excited in an unnatural way myself too after reading your posts concerning the D420. I need very cold showers now.

I hope there aren't too many women lurking in this thread. Between you and @buddhasummer , there have been some very uncomfortable comments regarding your anticipation, bwaahaha!

I hope there aren't too many women lurking in this thread. Between you and @buddhasummer , there have been some very uncomfortable comments regarding your anticipation, bwaahaha!

I had to tone down my comment above.

I wish I shared the enthusiasm you guys have for the new "Scrotum." While I am a fan of the center balanced poppet design, I've never taken a shine to the AIR I or it's descendants. I'm not sure why; perhaps it's the aesthetics.

Another reason for curbed enthusiasm IMHO is the parts count. Never mind the total parts count, but just look at the items to be replaced during a service visit. It's somewhere between 15 and 25! And (if it's OK to begin a sentence with and) we're not just talking about common items like o-rings and seats; there are sleeves, friction caps, stems, and the housing assembly (I guess that houses the hard seat) and God forbid, a decal! You and I don't need no stinking decals, but if it's part of the service kit the poor customer has to fork up for it.

I'm hoping I'm wrong here and your new toy will be all you want it to be-but I'll remain skeptical until a few of you have dived this new model for a couple of years and then serviced it.

Couv

Another reason for curbed enthusiasm IMHO is the parts count. Never mind the total parts count, but just look at the items to be replaced during a service visit. It's somewhere between 15 and 25! And (if it's OK to begin a sentence with and) we're not just talking about common items like o-rings and seats; there are sleeves, friction caps, stems, and the housing assembly (I guess that houses the hard seat) and God forbid, a decal! You and I don't need no stinking decals, but if it's part of the service kit the poor customer has to fork up for it.

I'm hoping I'm wrong here and your new toy will be all you want it to be-but I'll remain skeptical until a few of you have dived this new model for a couple of years and then serviced it.

Couv

...just look at the items to be replaced during a service visit. It's somewhere between 15 and 25!

Ah, the Grinch has arrived!I'm hoping I'm wrong here and your new toy will be all you want it to be-but I'll remain skeptical until a few of you have dived this new model for a couple of years and then serviced it.

I was waiting for someone to say, "Scrotum," lol!

I was waiting for someone to say, "Scrotum," lol!

Well, if you accept that the poppet comes as a single pre-assembled unit, then it's only 9 o-rings and yes, a decal. And I'm not sure why six of them are even changed, since they're static. Maybe you're supposed to remove the housing carrier every time for cleaning. But I'll grant you, it's not an indestructible, shiny Balanced Adjustable. If the plastic holds up as well as my G250, I'll be happy. I'm not sure that purge flap (part #44) will hold up over time, though it looks to be metal-backed. I'll be back on Christmas, and we can look together...

Ah, @couv ! As my mother always said, "Smile and the world smiles with you. Cry and you cry alone..."

You don't like the aesthetics? Tell you what. I'll dive my 420 with no decal. Like a big carb intake sticking up through the hood of my 409.

No, make that my 420.

Similar threads

- Replies

- 6

- Views

- 1,346

- Replies

- 2

- Views

- 604

- Replies

- 5

- Views

- 386

- Replies

- 6

- Views

- 290