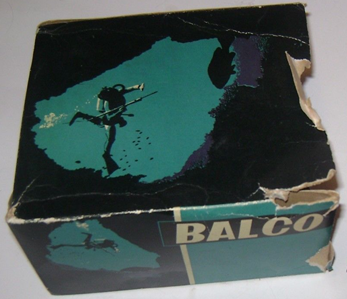

Let us start with the Greek diving equipment manufacturer Balco sub:

According to Facebook’s Balco Sub site, the manufacturing business also known as Eurobal Diving Company was established in 1954 by two partners, surnamed Ballas (Μπάλλας) and Colaros (Κολαρος), hence the company name Balco (BAL+CO).

At

Balco: Οι Ελληνικές μάσκες, βατραχοπέδιλα και ψαροντούφεκα., a Retromaniax forum member posted a 2013 thread entitled “Balco: Οι Ελληνικές μάσκες, βατραχοπέδιλα και ψαροντούφεκα” (Balco: Greek masks, fins and spearguns). According to the thread initiator, Balco Sub was first based in Kifissia, now one of the most expensive northern suburbs of Greece’s capital city Athens and traditionally home to rich Greek families and major Greek politicians.

The original poster continues, and I translate, “(Ballas and Colaros) processed rubber and made masks and fins as well as spearguns; (…) they actually exported to other countries, e.g. Australia, Germany and Lebanon.

One of them lived with his father and his wife (the father in a separate house) on the same property and we knew them well; both father and son happened to die of cancer, relatively soon one after the other. (…) I must tell you that when the father and the son died, the property was completely abandoned with hundreds of masks, spearguns and fins stored there in a total muddle. There were also raw materials from the factory, e.g. rubber in small balls and sulphur with a sweet-smelling chemical additive and magnesium salt too, all of these in some paper barrels. There was also a huge pile of paperwork from the company’s offices. (…) the property was not far from us, almost everything there was demolished in 2007 after it was bought by someone else, and nothing remains of these things I am telling you about (they were in storage and in fact in good condition until the end)”.

In 2019, “Balco team” updated this thread with the following information (my translation): “The Company is now called Balco sub. The headquarters is located on the industrial side of Menidi, manufacturing its products with the exact same know-how and quality since the 1970s. There are selected shops and diving centres all over Greece where you can find the products and soon the company’s new website at

www.balcosub.gr will be up and running”. Menidi was a northwestern suburb of Athens, Attica, Greece, and renamed Acharnes in 1915. The firm’s present address is EUROBAL DIVING CO. Georgia Frydas. 10 Themistokleous, 13671 Acharnes, ATTICA, GREECE.

More information about Balco sub and its underwater products midweek.