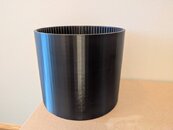

I'm not a fan of the commercially available rubber cylinder/tank boots for Steel LP85s, so I created a boot I could 3d print with ASA.

Specifically I'm using the boot with Faber LP85s, both painted and galvanized fit.

makerworld.com

makerworld.com

Specifically I'm using the boot with Faber LP85s, both painted and galvanized fit.

Scuba Cylinder Boot (Low Pressure Steel 85) by mehfridge MakerWorld: Download Free 3D Models

This is a tank/cylinder boot for low pressure steel 85cf cylinders. Specifically my cylinders I modeled this for are produced by Faber, but it may fit other low pressure 85 cf cylinders. I designed this model because the only commercially available tank boots for LP85 cylinders is a rubber...