Gents,

I never worry about water-in-oil in engines, because the oil temperature is high enough to evaporate any water from condensation.

What I worry is Bauer's overly optimistic reccomendation of 2,000 hours / 2 years using its top of the line N28355 synthetic oil for air. I am refering to Bauer Germany version of the User Manual. In the USA it is probably different manual...maybe.

Since compressor does not get its oil contaminated by fuel's combustion by-product like in an engine, it should stays pretty clean. Temperature wise I can say 50-60C is the hottest temperature at the oil filter output ( for my Bauer ), perhaps some hot spot at the cylinders where compression takes place but I guarantee the oil is much cooler than in an engine. Wear and tear contamination will be metal parts, since Bauer Mariner is air cooled, there is no possibility of engine coolant contaminating the oil from worn out gaskets or whatever. This leave us with water in oil introduced by ambient air and whatever water vapor piston blow-by will throw at the oil.

Nightime and daytime water condensation in oil crankcase part of the block is one thing, but what worry me a lot is the 5% piston blow by of the current Mariner block, its a 200 liter/minute or 7CFM.

5% will represent blow-by from possibly combination of 3 stages, the wettest will be the 1st stage because there is no water separator there. 2nd & 3rd stage piston blow-by will probably be 98.xx % drier because of the water separator function.

5% of 200 liter/minute is 10 liters and 1/3 of that is wet air from only cylinder 1 , that is 3.33 liters of air x 60 minutes run = 199.8 liters, let's make it 200 liters.

Bauer Mariner sucks air out of the crankcase to feed oil mist into cylinder 1. Whatever moist blow-by air probably get sucked too due to suction of cylinder 1 piston........but how much actually got sucked ? The oil filler neck has o-ring, so its quite a restriction to suck all air produced by piston blow by, the air coming thru the snorkle will be an easier path for the piston to suck. Dang...... suck here suck there....sounds like a porn flick

Assuming 90% of that 200 liters per hour of moist blow-by air will be removed by cylinder #1 suction. I still will get 10% of 200 liters = 20 liters per hour of moist air per 1 hour compressor run.

Now, I do not know how much positive pressure the compressor block will get during a compressor run. I am just trying to calculate the potential volume of water vapor introduced to the oil from piston blow-by, per hour. If the block stay at 1 ATM all the time, in theory there won't be extra air added, just air exchange. Bauer/compressor experts in this forum, please help me out in this.

If 20 liter worth of moist air is being squeezed of its moisture in the compressor crankcase per hour, there will be a lot of water in 200 hours of compressor operation, assuming 80% humidity. 20 liter x 200 hours is 4,000 liters or near two tanks full of 80CF.

Again assuming I screwed up the calculation and only 10% of 4,000 liters of air is what can contribute to water vapor conteminating the oil, I still have 400 liters of air worth of moisture to worry. 400 liters of wet 80% humidity air can juice out easy 3cc of water.

The Mariner block oil capacity is 2,800cc. That 3cc or milli liter is 1071 PPM of water in a 2,800cc of oil.

Oil engineer will find 1,000 PPM of water in oil scarry and bearing life will be reduced a great deal.

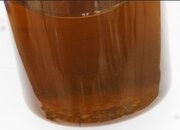

I am not very sure how to interpret the darker color of a used compressor oil , compared to light yellow color it is when brand new. How dirty is dirty ?

Oil do oxidize during use, or when exposed to metals and so on but what kind of color darkening resulted from that, if the water contemination equation is removed ?

Milky oil is sure sign of too much water, that I know. I have flooded ( and stalled ) my car engine twice in my lifetime. Its 4 feet of water for a small sedan, driving it thru a major flood... and feet of water in a Suzuki Vitara without a snorkle..

and feet of water in a Suzuki Vitara without a snorkle..

Combustion by-product in say a diesel engine or gasoline engine oil will make the oil look "dirty" and "black" oil is what diesel engine will produce in just 20 hours of engine run.

Using Chemlube 800 oil data sheet with its claimed excellent demulsibility, it is said that the oil is engineered to keep water in suspension as free water and not emulsified bla bla bla. If Bauer N28355 synthetic is as good as Chemlube 800 or equivalent, I may say that it seems 200 hours is the best I will get for my compressor working conditions/profile and at up to 33C ambient temperature.

This is a drain test I did on a 200 hours oil life :

- Compressor rested for 12 hours.

- Drain 500cc of the oil from the drain pipe, dang I should have drained all

- See water droplets in oil.....yep quite a few.

- Test water droplets using crackle/cooking test.....yep it blew like fire crackers

Findings :

I think the specific gravity of the Bauer oil is quite high. It takes approx 15 minutes for water droplets to drop to the bottom of the pyrex cup. I usually look for water in diesel fuel but never in oil like this and water in a 0.85 SG diesel fuel will hit the bottom of the container pretty fast.

Water saturation in this 200 hours old oil has surely hit the roof. Otherwise it will be dissolved in the oil and at 30C oil temperature, it is said it can dissolved up to 250 ppm or so and increasing with temperature and up to a certain limit.

Detecting and Controlling Water in Oil

How Water Causes Bearing Failure

Any oil or compressor expert opinions to add to this post , will be most appreciated.

Attached :

-Brand new oil from Bauer factory after 100 hours only. Bloody dirty !!

-New Oil

-200 hours old oil ( second oil change )

Thanks

IYA

I never worry about water-in-oil in engines, because the oil temperature is high enough to evaporate any water from condensation.

What I worry is Bauer's overly optimistic reccomendation of 2,000 hours / 2 years using its top of the line N28355 synthetic oil for air. I am refering to Bauer Germany version of the User Manual. In the USA it is probably different manual...maybe.

Since compressor does not get its oil contaminated by fuel's combustion by-product like in an engine, it should stays pretty clean. Temperature wise I can say 50-60C is the hottest temperature at the oil filter output ( for my Bauer ), perhaps some hot spot at the cylinders where compression takes place but I guarantee the oil is much cooler than in an engine. Wear and tear contamination will be metal parts, since Bauer Mariner is air cooled, there is no possibility of engine coolant contaminating the oil from worn out gaskets or whatever. This leave us with water in oil introduced by ambient air and whatever water vapor piston blow-by will throw at the oil.

Nightime and daytime water condensation in oil crankcase part of the block is one thing, but what worry me a lot is the 5% piston blow by of the current Mariner block, its a 200 liter/minute or 7CFM.

5% will represent blow-by from possibly combination of 3 stages, the wettest will be the 1st stage because there is no water separator there. 2nd & 3rd stage piston blow-by will probably be 98.xx % drier because of the water separator function.

5% of 200 liter/minute is 10 liters and 1/3 of that is wet air from only cylinder 1 , that is 3.33 liters of air x 60 minutes run = 199.8 liters, let's make it 200 liters.

Bauer Mariner sucks air out of the crankcase to feed oil mist into cylinder 1. Whatever moist blow-by air probably get sucked too due to suction of cylinder 1 piston........but how much actually got sucked ? The oil filler neck has o-ring, so its quite a restriction to suck all air produced by piston blow by, the air coming thru the snorkle will be an easier path for the piston to suck. Dang...... suck here suck there....sounds like a porn flick

Assuming 90% of that 200 liters per hour of moist blow-by air will be removed by cylinder #1 suction. I still will get 10% of 200 liters = 20 liters per hour of moist air per 1 hour compressor run.

Now, I do not know how much positive pressure the compressor block will get during a compressor run. I am just trying to calculate the potential volume of water vapor introduced to the oil from piston blow-by, per hour. If the block stay at 1 ATM all the time, in theory there won't be extra air added, just air exchange. Bauer/compressor experts in this forum, please help me out in this.

If 20 liter worth of moist air is being squeezed of its moisture in the compressor crankcase per hour, there will be a lot of water in 200 hours of compressor operation, assuming 80% humidity. 20 liter x 200 hours is 4,000 liters or near two tanks full of 80CF.

Again assuming I screwed up the calculation and only 10% of 4,000 liters of air is what can contribute to water vapor conteminating the oil, I still have 400 liters of air worth of moisture to worry. 400 liters of wet 80% humidity air can juice out easy 3cc of water.

The Mariner block oil capacity is 2,800cc. That 3cc or milli liter is 1071 PPM of water in a 2,800cc of oil.

Oil engineer will find 1,000 PPM of water in oil scarry and bearing life will be reduced a great deal.

I am not very sure how to interpret the darker color of a used compressor oil , compared to light yellow color it is when brand new. How dirty is dirty ?

Oil do oxidize during use, or when exposed to metals and so on but what kind of color darkening resulted from that, if the water contemination equation is removed ?

Milky oil is sure sign of too much water, that I know. I have flooded ( and stalled ) my car engine twice in my lifetime. Its 4 feet of water for a small sedan, driving it thru a major flood...

Combustion by-product in say a diesel engine or gasoline engine oil will make the oil look "dirty" and "black" oil is what diesel engine will produce in just 20 hours of engine run.

Using Chemlube 800 oil data sheet with its claimed excellent demulsibility, it is said that the oil is engineered to keep water in suspension as free water and not emulsified bla bla bla. If Bauer N28355 synthetic is as good as Chemlube 800 or equivalent, I may say that it seems 200 hours is the best I will get for my compressor working conditions/profile and at up to 33C ambient temperature.

This is a drain test I did on a 200 hours oil life :

- Compressor rested for 12 hours.

- Drain 500cc of the oil from the drain pipe, dang I should have drained all

- See water droplets in oil.....yep quite a few.

- Test water droplets using crackle/cooking test.....yep it blew like fire crackers

Findings :

I think the specific gravity of the Bauer oil is quite high. It takes approx 15 minutes for water droplets to drop to the bottom of the pyrex cup. I usually look for water in diesel fuel but never in oil like this and water in a 0.85 SG diesel fuel will hit the bottom of the container pretty fast.

Water saturation in this 200 hours old oil has surely hit the roof. Otherwise it will be dissolved in the oil and at 30C oil temperature, it is said it can dissolved up to 250 ppm or so and increasing with temperature and up to a certain limit.

Detecting and Controlling Water in Oil

How Water Causes Bearing Failure

Any oil or compressor expert opinions to add to this post , will be most appreciated.

Attached :

-Brand new oil from Bauer factory after 100 hours only. Bloody dirty !!

-New Oil

-200 hours old oil ( second oil change )

Thanks

IYA