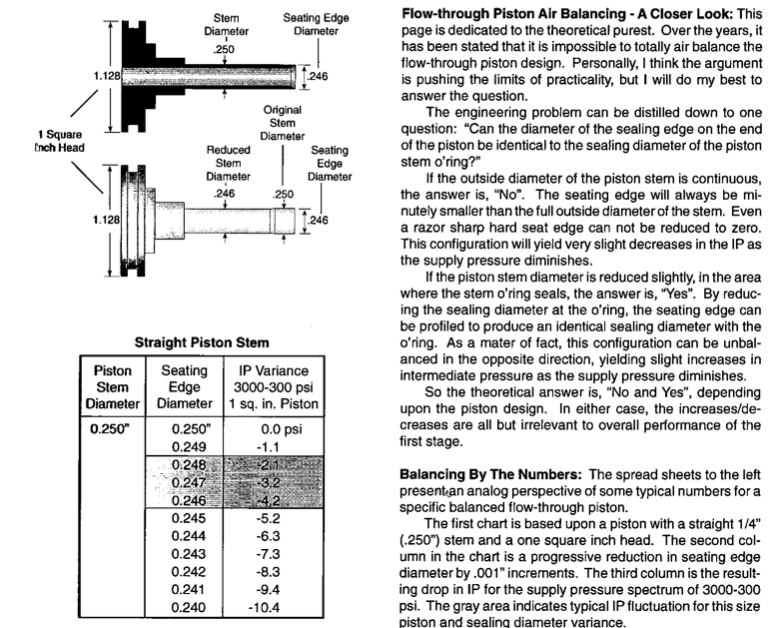

On "Regulator savvy book" section one page 31, the author described that a straight piston stem won't be actual air balanced because there exists annular area on the knife edge of a piston.

But that really confused me, I assume that when a piston first stage is in close position, there is no HP air between the piston knife edge and the HP seat. Hence, HP air should only exert vertical force on the piston outer diameter. I can't see any horizontal force by HP air that would make it unbalanced.

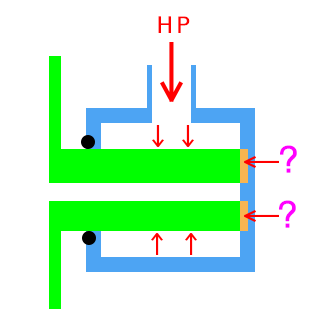

I drew an exaggerated figure to illustrate my question. Unless there is HP air at the orange area, there should be no horizontal force by HP air. How could the author comparing the diameter of the sealing edge on the end of the piston and the sealing diameter of the piston stem o'ring and then calculating annular area by them? Instead, I think he should only consider the outer diameter on each side. As long as the piston stem is straight, it should be air balanced. Isn't that right?

To sum up my question, does the author assume there is HP air in the orange area (HP seat) or did I miss anything? How is a straight piston not air balanced? Why does the inner annular area on the piston edge matter?

But that really confused me, I assume that when a piston first stage is in close position, there is no HP air between the piston knife edge and the HP seat. Hence, HP air should only exert vertical force on the piston outer diameter. I can't see any horizontal force by HP air that would make it unbalanced.

I drew an exaggerated figure to illustrate my question. Unless there is HP air at the orange area, there should be no horizontal force by HP air. How could the author comparing the diameter of the sealing edge on the end of the piston and the sealing diameter of the piston stem o'ring and then calculating annular area by them? Instead, I think he should only consider the outer diameter on each side. As long as the piston stem is straight, it should be air balanced. Isn't that right?

To sum up my question, does the author assume there is HP air in the orange area (HP seat) or did I miss anything? How is a straight piston not air balanced? Why does the inner annular area on the piston edge matter?