You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

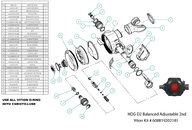

Hog 2nd oring question

- Thread starter Candiru

- Start date

Please register or login

Welcome to ScubaBoard, the world's largest scuba diving community. Registration is not required to read the forums, but we encourage you to join. Joining has its benefits and enables you to participate in the discussions.

Benefits of registering include

- Ability to post and comment on topics and discussions.

- A Free photo gallery to share your dive photos with the world.

- You can make this box go away

Yes or no. On the Classic, a 2.0 x 1.0 is specified on the schematic. That's odd, because on the D2 at least, it's an impossible to find 2.42 x 0.82 mm oring, and the poppets measure out the same to me. Not only that, the D1, Classic and D2 all have the same poppet and balance chamber part numbers.

I found a Precision Associates o-ring that has about the same performance characteristics as the 2.42 x 0.82, but the size escapes me. If you really want to try it, DM me and I'll search for the tests I made.

The size is critical to maintain both a seal and adequately low friction against the balance chamber. So unless they changed both the poppet and balance chamber specs between the Classic and the D2, the 2.42 x 0.82 is the o-ring, notwithstanding the schematic, because they all have the same poppet and balance chamber.

And the Signature that Chris designed for Deep6 has that same 2.42 x 0.82. I'll ask him next week at DEMA.

O-ring pics are from my D1 kit, despite the schematic showing 2 x 1 mm!!

Having seen the same issue with other overseas OEM's, my bet is that the o-ring was changed by the manufacturer after the schematics were released.

I found a Precision Associates o-ring that has about the same performance characteristics as the 2.42 x 0.82, but the size escapes me. If you really want to try it, DM me and I'll search for the tests I made.

The size is critical to maintain both a seal and adequately low friction against the balance chamber. So unless they changed both the poppet and balance chamber specs between the Classic and the D2, the 2.42 x 0.82 is the o-ring, notwithstanding the schematic, because they all have the same poppet and balance chamber.

And the Signature that Chris designed for Deep6 has that same 2.42 x 0.82. I'll ask him next week at DEMA.

O-ring pics are from my D1 kit, despite the schematic showing 2 x 1 mm!!

Having seen the same issue with other overseas OEM's, my bet is that the o-ring was changed by the manufacturer after the schematics were released.

Attachments

- Messages

- 8,627

- Reaction score

- 7,329

- # of dives

- 2500 - 4999

Does anyone have the figures for how many millions of breaths you can take on one set of those orings

Do they get some sort of a sheen or get a flat, on their outside surface, extreme diameter

Maybe China makes all that stuff they make because we throw out all that stuff we've got

Do they get some sort of a sheen or get a flat, on their outside surface, extreme diameter

Maybe China makes all that stuff they make because we throw out all that stuff we've got

Thanks in advance for checking with Chris. I’m in the process of setting up my reg sets for deco procedures in December.Yes or no. On the Classic, a 2.0 x 1.0 is specified on the schematic. That's odd, because on the D2 at least, it's an impossible to find 2.42 x 0.82 mm oring, and the poppets measure out the same to me. Not only that, the D1, Classic and D2 all have the same poppet and balance chamber part numbers.

I found a Precision Associates o-ring that has about the same performance characteristics as the 2.42 x 0.82, but the size escapes me. If you really want to try it, DM me and I'll search for the tests I made.

The size is critical to maintain both a seal and adequately low friction against the balance chamber. So unless they changed both the poppet and balance chamber specs between the Classic and the D2, the 2.42 x 0.82 is the o-ring, notwithstanding the schematic, because they all have the same poppet and balance chamber.

And the Signature that Chris designed for Deep6 has that same 2.42 x 0.82. I'll ask him next week at DEMA.

O-ring pics are from my D1 kit, despite the schematic showing 2 x 1 mm!!

Having seen the same issue with other overseas OEM's, my bet is that the o-ring was changed by the manufacturer after the schematics were released.

O-ring substitution is a huge discussion issue for DIY guys (especially if you can't find an obscure size like 2.42 x 0.82).

To reprise a 20‐minute seminar discussion in a couple of paragraphs...

If it's a static o-ring and it seals, use whatever size you like. Choose your material based on your mission requirements (silicone, Nitrile, EPDM, FKM/Viton, polyurethane).

Example? The US machining standard for LP ports mandates a 3-903. Some mfrs use them, but most don't. Instead, it's a 2-010 or 2-011. Rarely, a 2-010 won't seal, because the port o-ring sealing surfaces are the top side and the OD, and a 2-010 grabs the plug too tightly. But... whatever.

And for HP applications, a high duro may be key, if the machining is sloppy, to reduce extrusion. Then again, Aqualung uses Sh80 instead of 90 because their machining is tight enough, and some mfrs even use Sh70 in certain HP locations.

For a "semi-dynamic" o-ring (think turret seal to the cap, or second stage to the LP hose), the above applies, with added considerations for abrasion resistance and suppleness.

Example: the imported "Viton" hose o-ring that simply fractures at the second stage or the angled adapter because there's too much carbon black in the compound (because it's cheaper to manufacture that way).

For a truly dynamic o-ring like the poppet shaft o-rings for the flyweight components being discussed here, the new added consideration is friction.

For the best seal between a crudely molded plastic poppet and balance chamber, you might want to decrease durometer to 50 from 70. But then, "grabbyness" of the o-ring increases, and while the seal may work with a wider variety of sizes, friction between components increases.

To "make things work" when you can't find a size smaller than 1mm, it's tempting to stretch the oring over the groove of the poppet shaft, using stretch to decrease the effective cross section. But now, either the o-ring may not seal because it's pulled away from the ID of the balance chamber, or if it seals, the stretched oring has less "give", and friction may be too high between the parts.

If you're experimenting with an available size for a poppet, here's a crude pair of tricks that will keep your toy working, and probably maintain performance within safe limits.

1) Do a "bounce test". Assemble your seat, poppet and balance chamber WITHOUT the spring. Firmly press the poppet and seat against a polished surface like glass or the glossy side of the lid of a yogurt container. With the hole in the LP seat now occluded, and the balance chamber just engaged on the end of the shaft, "bounce" the balance chamber on the shaft with your finger.

a) if the balance chamber collapses, you may not have a seal between shaft OD and balance chamber ID;

b) if the balance chamber drops on the shaft, but has a little compressive resistance before it hits bottom, you've got a seal. But the friction between the components prevents the very lightweight balance chamber from being popped back up on the shaft by the air compressed inside. Too much friction. Lube the components and try again. If it still won't bounce back, your reg might work, but at some point may freeflow a little if the poppet assembly gets stuck in the collapsed position. The reason is that when the poppet assembly is short and collapsed, the lightweight mechanical spring is inadequate to hold back IP without the assistance of the pneumatic spring. Then again, if the balance chamber pressure is maintained, the reg may seal, but valve action will be less crisp.

c) if the balance chamber pops back up, that's a good sign that both seal and friction are appropriate.

2) The second of the two tests is to measure static friction. Place the poppet assembly (again, WITHOUT the spring) on a digital kitchen/postal scale with the units on "grams". Carefully push on a balance chamber that is mounted partway on the shaft. Try to determine the grams of pressure when the complex finally gives way and the balance chamber moves. You'll have to repeat this several times to get an "average" value. Typically, if a poppet assembly without spring overcomes static friction at around 25-30g, you've got a good working seal. If it's much higher than that, I'd be surprised that you got a bounce at all. If it's lower than 15g, your dynamic seal may occasionally leak, and you need a larger o-ring.

Keep in mind that poppet o-rings seal like a port plug: against the ID of the balance chamber on their outer perimeter, and against the top side of the groove in the poppet shaft when driven up by IP inside the balance chamber.

Making DIY substitutions to lightweight dynamic components is fraught with risk, notwithstanding the frustration of paying $19-35 for a service kit that's nothing but a $4 top hat seat and a few o-rings. Then again, if you go to the work of special ordering a rare tiny o-ring of the correct size so you don't have to buy a kit, you'll run up against setup charges and minimum order quantities, and end up paying $2 each just for Nitrile, like I did at PAI. Marcorubber and Ace were even worse! You can't win. It just has to be a labor of love.

To reprise a 20‐minute seminar discussion in a couple of paragraphs...

If it's a static o-ring and it seals, use whatever size you like. Choose your material based on your mission requirements (silicone, Nitrile, EPDM, FKM/Viton, polyurethane).

Example? The US machining standard for LP ports mandates a 3-903. Some mfrs use them, but most don't. Instead, it's a 2-010 or 2-011. Rarely, a 2-010 won't seal, because the port o-ring sealing surfaces are the top side and the OD, and a 2-010 grabs the plug too tightly. But... whatever.

And for HP applications, a high duro may be key, if the machining is sloppy, to reduce extrusion. Then again, Aqualung uses Sh80 instead of 90 because their machining is tight enough, and some mfrs even use Sh70 in certain HP locations.

For a "semi-dynamic" o-ring (think turret seal to the cap, or second stage to the LP hose), the above applies, with added considerations for abrasion resistance and suppleness.

Example: the imported "Viton" hose o-ring that simply fractures at the second stage or the angled adapter because there's too much carbon black in the compound (because it's cheaper to manufacture that way).

For a truly dynamic o-ring like the poppet shaft o-rings for the flyweight components being discussed here, the new added consideration is friction.

For the best seal between a crudely molded plastic poppet and balance chamber, you might want to decrease durometer to 50 from 70. But then, "grabbyness" of the o-ring increases, and while the seal may work with a wider variety of sizes, friction between components increases.

To "make things work" when you can't find a size smaller than 1mm, it's tempting to stretch the oring over the groove of the poppet shaft, using stretch to decrease the effective cross section. But now, either the o-ring may not seal because it's pulled away from the ID of the balance chamber, or if it seals, the stretched oring has less "give", and friction may be too high between the parts.

If you're experimenting with an available size for a poppet, here's a crude pair of tricks that will keep your toy working, and probably maintain performance within safe limits.

1) Do a "bounce test". Assemble your seat, poppet and balance chamber WITHOUT the spring. Firmly press the poppet and seat against a polished surface like glass or the glossy side of the lid of a yogurt container. With the hole in the LP seat now occluded, and the balance chamber just engaged on the end of the shaft, "bounce" the balance chamber on the shaft with your finger.

a) if the balance chamber collapses, you may not have a seal between shaft OD and balance chamber ID;

b) if the balance chamber drops on the shaft, but has a little compressive resistance before it hits bottom, you've got a seal. But the friction between the components prevents the very lightweight balance chamber from being popped back up on the shaft by the air compressed inside. Too much friction. Lube the components and try again. If it still won't bounce back, your reg might work, but at some point may freeflow a little if the poppet assembly gets stuck in the collapsed position. The reason is that when the poppet assembly is short and collapsed, the lightweight mechanical spring is inadequate to hold back IP without the assistance of the pneumatic spring. Then again, if the balance chamber pressure is maintained, the reg may seal, but valve action will be less crisp.

c) if the balance chamber pops back up, that's a good sign that both seal and friction are appropriate.

2) The second of the two tests is to measure static friction. Place the poppet assembly (again, WITHOUT the spring) on a digital kitchen/postal scale with the units on "grams". Carefully push on a balance chamber that is mounted partway on the shaft. Try to determine the grams of pressure when the complex finally gives way and the balance chamber moves. You'll have to repeat this several times to get an "average" value. Typically, if a poppet assembly without spring overcomes static friction at around 25-30g, you've got a good working seal. If it's much higher than that, I'd be surprised that you got a bounce at all. If it's lower than 15g, your dynamic seal may occasionally leak, and you need a larger o-ring.

Keep in mind that poppet o-rings seal like a port plug: against the ID of the balance chamber on their outer perimeter, and against the top side of the groove in the poppet shaft when driven up by IP inside the balance chamber.

Making DIY substitutions to lightweight dynamic components is fraught with risk, notwithstanding the frustration of paying $19-35 for a service kit that's nothing but a $4 top hat seat and a few o-rings. Then again, if you go to the work of special ordering a rare tiny o-ring of the correct size so you don't have to buy a kit, you'll run up against setup charges and minimum order quantities, and end up paying $2 each just for Nitrile, like I did at PAI. Marcorubber and Ace were even worse! You can't win. It just has to be a labor of love.

Tanks A Lot

Contributor

These custom sizes is something I truly dislike. I'm glad that Scubapro got over their nonsense with the Parker O-rings a long time ago.

While I understand from an engineering point of view that it's easier to design the part and then match an O-ring to, I believe taking a standard O-ring and designing the part around it is the more elegant choice in the long run. But I guess sometimes certain things are hard to avoid and supplier capabilities play a major role.

For what it's worth, if you buy a couple of thousand O-rings from a supplier, you can get custom made whatever you want. If they even have the molds setup for something very close to what you want, it's surprisingly cheap. A bag with 1000 O-rings or so will probably cost you 20€.

Arcus has a batch of O-rings arguably so close to what you are looking for at 2.37 x 0.8 that you will not notice a difference.

While this batch is made from NBR, you can get whatever material you want, although prices will be considerably higher.

While I understand from an engineering point of view that it's easier to design the part and then match an O-ring to, I believe taking a standard O-ring and designing the part around it is the more elegant choice in the long run. But I guess sometimes certain things are hard to avoid and supplier capabilities play a major role.

For what it's worth, if you buy a couple of thousand O-rings from a supplier, you can get custom made whatever you want. If they even have the molds setup for something very close to what you want, it's surprisingly cheap. A bag with 1000 O-rings or so will probably cost you 20€.

Arcus has a batch of O-rings arguably so close to what you are looking for at 2.37 x 0.8 that you will not notice a difference.

While this batch is made from NBR, you can get whatever material you want, although prices will be considerably higher.

And Europe once again gets something that the Ameriki can't have. Good on you guys!Arcus has a batch of O-rings arguably so close to what you are looking for at 2.37 x 0.8 that you will not notice a difference.

(Now if only you had a comprehensive scuba tool distributor)

^--- This!!I believe taking a standard O-ring and designing the part around it is the more elegant choice in the long run.

O-ring substitution is a huge discussion issue for DIY guys (especially if you can't find an obscure size like 2.42 x 0.82).

To reprise a 20‐minute seminar discussion in a couple of paragraphs...

If it's a static o-ring and it seals, use whatever size you like. Choose your material based on your mission requirements (silicone, Nitrile, EPDM, FKM/Viton, polyurethane).

Example? The US machining standard for LP ports mandates a 3-903. Some mfrs use them, but most don't. Instead, it's a 2-010 or 2-011. Rarely, a 2-010 won't seal, because the port o-ring sealing surfaces are the top side and the OD, and a 2-010 grabs the plug too tightly. But... whatever.

And for HP applications, a high duro may be key, if the machining is sloppy, to reduce extrusion. Then again, Aqualung uses Sh80 instead of 90 because their machining is tight enough, and some mfrs even use Sh70 in certain HP locations.

For a "semi-dynamic" o-ring (think turret seal to the cap, or second stage to the LP hose), the above applies, with added considerations for abrasion resistance and suppleness.

Example: the imported "Viton" hose o-ring that simply fractures at the second stage or the angled adapter because there's too much carbon black in the compound (because it's cheaper to manufacture that way).

For a truly dynamic o-ring like the poppet shaft o-rings for the flyweight components being discussed here, the new added consideration is friction.

For the best seal between a crudely molded plastic poppet and balance chamber, you might want to decrease durometer to 50 from 70. But then, "grabbyness" of the o-ring increases, and while the seal may work with a wider variety of sizes, friction between components increases.

To "make things work" when you can't find a size smaller than 1mm, it's tempting to stretch the oring over the groove of the poppet shaft, using stretch to decrease the effective cross section. But now, either the o-ring may not seal because it's pulled away from the ID of the balance chamber, or if it seals, the stretched oring has less "give", and friction may be too high between the parts.

If you're experimenting with an available size for a poppet, here's a crude pair of tricks that will keep your toy working, and probably maintain performance within safe limits.

1) Do a "bounce test". Assemble your seat, poppet and balance chamber WITHOUT the spring. Firmly press the poppet and seat against a polished surface like glass or the glossy side of the lid of a yogurt container. With the hole in the LP seat now occluded, and the balance chamber just engaged on the end of the shaft, "bounce" the balance chamber on the shaft with your finger.

a) if the balance chamber collapses, you may not have a seal between shaft OD and balance chamber ID;

b) if the balance chamber drops on the shaft, but has a little compressive resistance before it hits bottom, you've got a seal. But the friction between the components prevents the very lightweight balance chamber from being popped back up on the shaft by the air compressed inside. Too much friction. Lube the components and try again. If it still won't bounce back, your reg might work, but at some point may freeflow a little if the poppet assembly gets stuck in the collapsed position. The reason is that when the poppet assembly is short and collapsed, the lightweight mechanical spring is inadequate to hold back IP without the assistance of the pneumatic spring. Then again, if the balance chamber pressure is maintained, the reg may seal, but valve action will be less crisp.

c) if the balance chamber pops back up, that's a good sign that both seal and friction are appropriate.

2) The second of the two tests is to measure static friction. Place the poppet assembly (again, WITHOUT the spring) on a digital kitchen/postal scale with the units on "grams". Carefully push on a balance chamber that is mounted partway on the shaft. Try to determine the grams of pressure when the complex finally gives way and the balance chamber moves. You'll have to repeat this several times to get an "average" value. Typically, if a poppet assembly without spring overcomes static friction at around 25-30g, you've got a good working seal. If it's much higher than that, I'd be surprised that you got a bounce at all. If it's lower than 15g, your dynamic seal may occasionally leak, and you need a larger o-ring.

Keep in mind that poppet o-rings seal like a port plug: against the ID of the balance chamber on their outer perimeter, and against the top side of the groove in the poppet shaft when driven up by IP inside the balance chamber.

Making DIY substitutions to lightweight dynamic components is fraught with risk, notwithstanding the frustration of paying $19-35 for a service kit that's nothing but a $4 top hat seat and a few o-rings. Then again, if you go to the work of special ordering a rare tiny o-ring of the correct size so you don't have to buy a kit, you'll run up against setup charges and minimum order quantities, and end up paying $2 each just for Nitrile, like I did at PAI. Marcorubber and Ace were even worse! You can't win. It just has to be a labor of love.

I am not sure if its lost in the sauce and perhaps I missed it, but I am still stumped trying to understand why some of the HOG 2nd stages spec the 2x1mm o-rings given the identical part numbers for the poppet pistons and balance chambers where the HOG Classic 2nd stage specs the 2.42x0.82mm.

The substition, as you noted, makes sense from the DIY perspective, but why is the OEM doing this/why do they specify 2 different o-rings for the same sets of internal parts?

-Z

Similar threads

- Replies

- 12

- Views

- 672

- Replies

- 14

- Views

- 1,555

- Replies

- 0

- Views

- 233