Let me preface this with I know little to nothing about compressors let alone this Rix.

That out of the way, I’m a machinist and I’m trying to help fix the 3rd stage head on a Rix 3K3B-44. I’ll do my best to describe the problem but if I say something non-sensical my apologies in advance.

The intake valve seat keeps failing and as I understand it, too high of a pressure is going back to 2nd stage components.

We have 3 heads here, the oldest of which appears to be a metal seat, the 2 “newer” heads have a plastic valve seat. According to Rix, the valve seat is made from Meldin 7021. Assembly drawings we have don’t show a valve seat but Rix was able to give us a drawing that matched the damaged valve seat I was able to extract.

The problem I’m having is getting the valve seat I’ve machined to screw in. My parts are dead nuts, but the female threads in the head have horrible build up. Cleaning up the threads is problematic because they go to a sharp corner and there is only 3 threads anyways (part is .12” pitch is ~.041”). It appears as though the head originally had the threads cut and then a round pressed in to create a hard corner / flat bottom that was then finished machined after the press.

First question, does anyone know if there was a design change , I.e., did the original part use a metal on metal valve seat that was then changed later to a plastic seat?

Has anyone ever repaired one of these and do you have any advice?

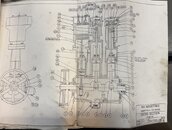

Pics of the assembly from top down :

That out of the way, I’m a machinist and I’m trying to help fix the 3rd stage head on a Rix 3K3B-44. I’ll do my best to describe the problem but if I say something non-sensical my apologies in advance.

The intake valve seat keeps failing and as I understand it, too high of a pressure is going back to 2nd stage components.

We have 3 heads here, the oldest of which appears to be a metal seat, the 2 “newer” heads have a plastic valve seat. According to Rix, the valve seat is made from Meldin 7021. Assembly drawings we have don’t show a valve seat but Rix was able to give us a drawing that matched the damaged valve seat I was able to extract.

The problem I’m having is getting the valve seat I’ve machined to screw in. My parts are dead nuts, but the female threads in the head have horrible build up. Cleaning up the threads is problematic because they go to a sharp corner and there is only 3 threads anyways (part is .12” pitch is ~.041”). It appears as though the head originally had the threads cut and then a round pressed in to create a hard corner / flat bottom that was then finished machined after the press.

First question, does anyone know if there was a design change , I.e., did the original part use a metal on metal valve seat that was then changed later to a plastic seat?

Has anyone ever repaired one of these and do you have any advice?

Pics of the assembly from top down :