I sent one of my tanks for an annual VIP to my LDS and as they were inspecting it, they found a tiny hold on the thread and said that they could not fill the tank with air. I also have a spare K valve (BlueSteel) and it too has a tiny hole. So, are these valves shot? And do I need a valve then? Thanks.

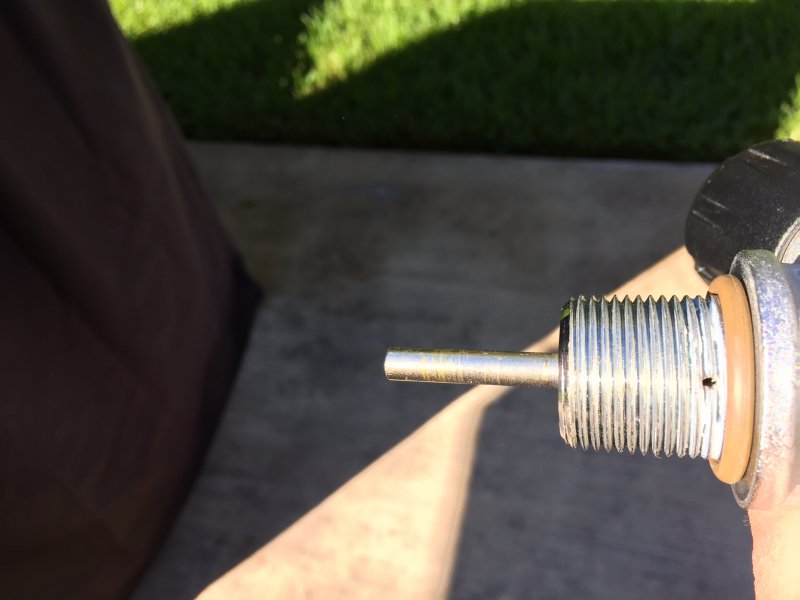

Photo from Beuchat Y-Valve with the tiny hole:

Photo from Beuchat Y-Valve with the tiny hole: