OK, I think it’s time to do a little review of how the 109/Balanced Adjustable/and G2xx series second stages differ from other demand valve regulators. The first clue is that they all have Single Adjustment Valves. The Diver Inhalation Adjustment Knob notwithstanding, outside of replacing the spring the only means of adjusting the cracking effort is with the adjustable orifice. Our favorite second stage(s) also has a NON ADJUSTABLE LEVER. Unlike dual-adjustment demand valves, where the lever slack can be taken up and the height adjusted, the lever height in these barrel poppet designs cannot be adjusted. “Huh? But I read….I saw…I heard…” No, that’s just a slight inaccuracy in terminology. Yes, lever height is affected when the orifice is mated up with the poppet seat-but that is not the function of the orifice. In a perfect world the hard seat on the orifice and the soft seat on the poppet would kiss and shut off the IP downstream force without dropping the lever. But we know that’s not the case. Before going any further, let’s have a look at a barrel poppet design cutaway.

Here we see the poppet assembly installed and the orifice backed away. Notice how the angle of the lever tabs sets the lever height? The spring pushes the poppet feet against the lever tabs. The lever tabs are also aligned with the vertical sides of the square broach in the air barrel. This is where we want to do our first lever height check-before adjusting the cracking pressure. If the lever is too low, it will affect demand effort and the shorter stroke will limit the opening between the poppet and the orifice thereby reducing gas flow. If the lever is too high, then the diaphragm cover will exert pressure on the lever causing freeflow. When this happens, some technicians “fix” the issue by adjusting the orifice in to stop the flow. Too much pressure from the orifice on the seat reduces performance by raising the cracking effort. Now we can see why near perfect lever height is critical from the start. So how do we know if the lever height is correct? Very simple-measure it. Remember, we want our first check to be before the orifice engages the seat. So, measure with all the components in place except the orifice. Have a look at the air barrel. Notice the flat area just under the lever? Measure from the flat spot on the barrel to the top of the lever arms. That dimension should be 0.7 inches (give or take a little.)

Here we see the poppet assembly installed and the orifice backed away. Notice how the angle of the lever tabs sets the lever height? The spring pushes the poppet feet against the lever tabs. The lever tabs are also aligned with the vertical sides of the square broach in the air barrel. This is where we want to do our first lever height check-before adjusting the cracking pressure. If the lever is too low, it will affect demand effort and the shorter stroke will limit the opening between the poppet and the orifice thereby reducing gas flow. If the lever is too high, then the diaphragm cover will exert pressure on the lever causing freeflow. When this happens, some technicians “fix” the issue by adjusting the orifice in to stop the flow. Too much pressure from the orifice on the seat reduces performance by raising the cracking effort. Now we can see why near perfect lever height is critical from the start. So how do we know if the lever height is correct? Very simple-measure it. Remember, we want our first check to be before the orifice engages the seat. So, measure with all the components in place except the orifice. Have a look at the air barrel. Notice the flat area just under the lever? Measure from the flat spot on the barrel to the top of the lever arms. That dimension should be 0.7 inches (give or take a little.)

Why do I suggest measuring from the air barrel to the top of the lever rather than using some distance over the top of the case? Well, with the exception of the 109 and Balanced Adjustable, most of the assembling and tuning is done with the air barrel out of the case. Having said that, the dimension can also be checked easily with the air barrel installed in the case.

What if the lever height is not correct? It’s time to disassemble the valve assembly, remove the lever and replace it with one that is known to be good. Sorry, more or less spring pressure will not help. And as we’ve seen, adjusting the lever height with the orifice will lead to poor performance. On top of that, we haven’t even started to adjust the cracking pressure….until now.

What if the lever height is not correct? It’s time to disassemble the valve assembly, remove the lever and replace it with one that is known to be good. Sorry, more or less spring pressure will not help. And as we’ve seen, adjusting the lever height with the orifice will lead to poor performance. On top of that, we haven’t even started to adjust the cracking pressure….until now.

OK, adjusting the cracking effort is pretty straight forward and is a subject for another thread. This one is getting too long anyway.

This one is getting too long anyway.

Now that we have a known good lever installed, the cracking effort is where we want it, and the air barrel assembly is installed, guess what? It’s time to do another lever height check. Again?! Yes, but this time it’s even easier. Simply place the diaphragm over the lever and inspect it for fit. The outside edge of the diaphragm should sit in the case with no gaps around the periphery and no wrinkles in the skirt.

Comme ca.

We’re almost done. Put all the friction rings, diaphragm covers, purge buttons, etc back in place and do a breathing resistance, freeflow, vacuum, and bubble check. All good? I thought so!

We’re almost done. Put all the friction rings, diaphragm covers, purge buttons, etc back in place and do a breathing resistance, freeflow, vacuum, and bubble check. All good? I thought so!

Now, about that nonadjustable lever. Well, some will say I lied. Scubapro maintains the lever is not to be bent, spindled, or mutilated. However, for the daring, there is a tool out there made specifically to check and adjust some of the levers.....not the new curly feet ones, but I've never had an issue with the new ones.

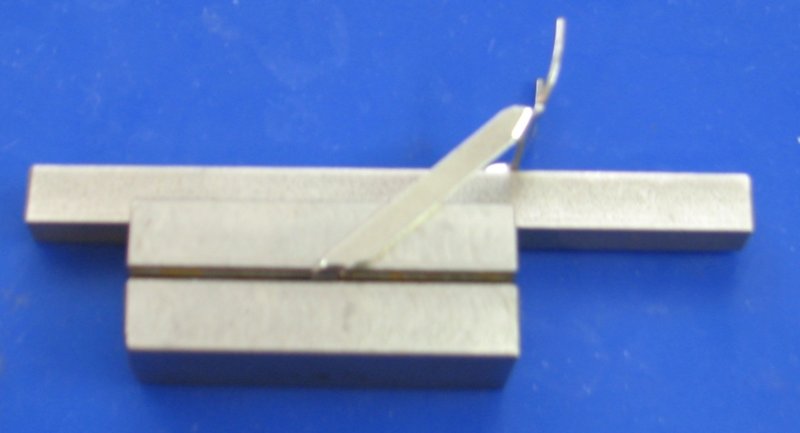

What if you’re not rich like me and cannot source one? Only a fool with a death wish would try this, but for your entertainment here is a picture of another method of adjusting the lever tabs.

What if you’re not rich like me and cannot source one? Only a fool with a death wish would try this, but for your entertainment here is a picture of another method of adjusting the lever tabs.

Regardless of how foolish one is, I suppose ensuring both lever tabs are exactly even would be prudent.

Couv

Thanks to Pete Wolfinger, author of SP Technical Service Manual –First edition 10/01/1994 Who I stole most of the legitimate information above from. Also to Herman Mowery, owner, manager and janitor of Custom Scuba Tools.

Why do I suggest measuring from the air barrel to the top of the lever rather than using some distance over the top of the case? Well, with the exception of the 109 and Balanced Adjustable, most of the assembling and tuning is done with the air barrel out of the case. Having said that, the dimension can also be checked easily with the air barrel installed in the case.

OK, adjusting the cracking effort is pretty straight forward and is a subject for another thread.

Now that we have a known good lever installed, the cracking effort is where we want it, and the air barrel assembly is installed, guess what? It’s time to do another lever height check. Again?! Yes, but this time it’s even easier. Simply place the diaphragm over the lever and inspect it for fit. The outside edge of the diaphragm should sit in the case with no gaps around the periphery and no wrinkles in the skirt.

Comme ca.

Now, about that nonadjustable lever. Well, some will say I lied. Scubapro maintains the lever is not to be bent, spindled, or mutilated. However, for the daring, there is a tool out there made specifically to check and adjust some of the levers.....not the new curly feet ones, but I've never had an issue with the new ones.

Regardless of how foolish one is, I suppose ensuring both lever tabs are exactly even would be prudent.

Couv

Thanks to Pete Wolfinger, author of SP Technical Service Manual –First edition 10/01/1994 Who I stole most of the legitimate information above from. Also to Herman Mowery, owner, manager and janitor of Custom Scuba Tools.