The very last model of the D400 included big changes, discussed in Service Bulletin #268 (attached below). The "improvements" included a redesign of the housing, eliminating the fragile metal knife edge in favor of a new housing with a replaceable "techno- polymer" orifice.

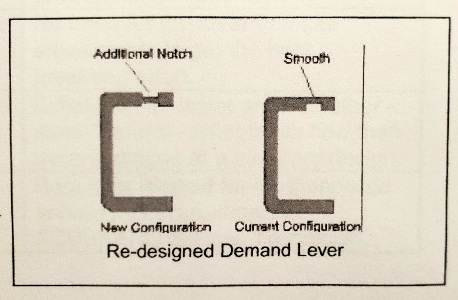

The lever was also changed to increase poppet opening and air flow by effectively doubling the mechanical advantage of the short arm of the lever.

Most significant was the change in knife edge. The "techno-polymer" edge was durable, no doubt about it. Only the new D420 plastic knife edge seems to be better. But its contour was decidedly rounded, and it was rare to be able to seal at less than 0.8"WC. The seat material in later poppets seems to have become harder, IMO. With a smooth but dull plastic orifice, that made for a better mating at lower cracking effort. The earlier, softer seats would better tolerate a nicked metal knife edge, but those same poppets would require too much spring tension to seal against a duller edge (with its larger total surface area). It became a Catch-22 to experiment with multiple seats to get best performance. As noted above, using @Kupu 's technique with the proper Duro 2-104 o-ring may be the solution to all this:

solution for D-series poppet seat DIY?

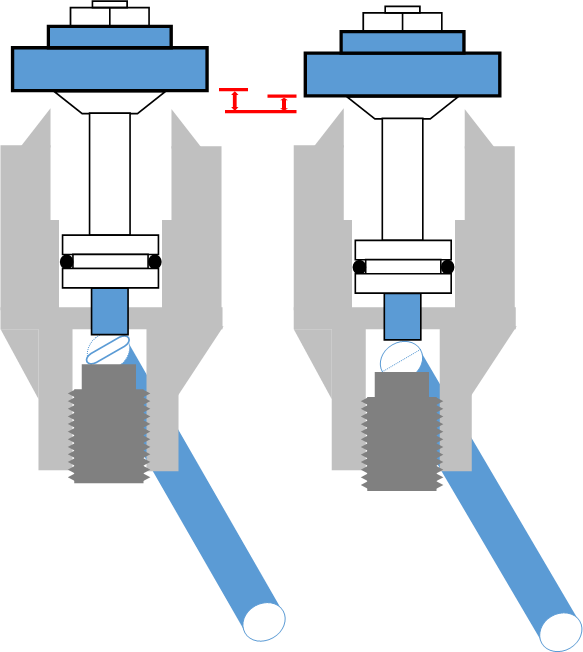

With regard to the lever, the sharper contact point where the new style lever contacted the nib at the bottom of the poppet made for slightly increased friction, although total valve opening was improved. The mechanics are suggested by the diagram below:

In any case, it is occasionally possible to "downgrade" to an older metal orifice, and lots of smooth D400 levers are around. It's worth experimenting to see if you can identify a difference in performance.

From a service standpoint with the very last D400 model, the only new challenge is getting the orifice out of the housing without damaging it, for there are no more available techno-polymer orifices on the market that I have seen.

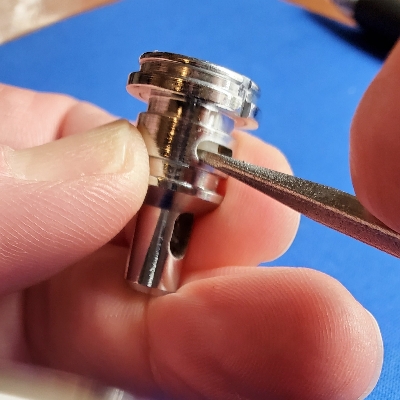

To remove the orifice, use a small flat blade screwdriver to lever up on the two tabs in the oval holes in the side of the housing.

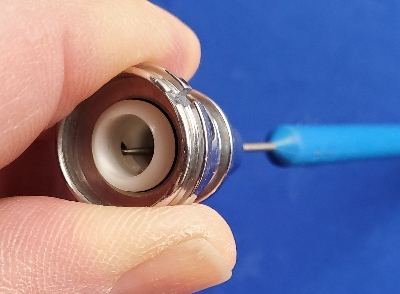

Then, using a straight blunt pick, carefully engage the side of the orifice from below through the stem of the housing, and carefully push up.

If the pick is engaged, the orifice will slide out. If not, it will slip and likely scratch your knife edge.

The static o-rings that seal the orifice to the housing are spec'ed by Scubapro as AS568 5-179 duro 70. However, this is roughly a 1x6mm oring, and the lands in the techno-polymer orifice measure 8.37mm diameter. A 1x6mm therefore requires significant stretch, and I am surprised at the specification. A 1mm x 7mm duro 70 fits quite well and is my choice, but as a static oring it probably makes little difference either way, as long as you can insert the orifice and it seals in the housing.

Replacing the orifice requires careful, symmetric downward pressure on the knife edge with nothing harder than your thumb. Resurfacing this knife edge will be discussed in an upcoming D-series restoration thread.

Well, that's about all I have to offer on this reg. I hope the tips above have been helpful. As always, this is just one guy's opinion, and with @Kupu 's poppet invention as an example, new ideas are always appearing for keeping this old beauty in service. I welcome any new ideas or differing opinions regarding service or performance of this regulator.

The lever was also changed to increase poppet opening and air flow by effectively doubling the mechanical advantage of the short arm of the lever.

Most significant was the change in knife edge. The "techno-polymer" edge was durable, no doubt about it. Only the new D420 plastic knife edge seems to be better. But its contour was decidedly rounded, and it was rare to be able to seal at less than 0.8"WC. The seat material in later poppets seems to have become harder, IMO. With a smooth but dull plastic orifice, that made for a better mating at lower cracking effort. The earlier, softer seats would better tolerate a nicked metal knife edge, but those same poppets would require too much spring tension to seal against a duller edge (with its larger total surface area). It became a Catch-22 to experiment with multiple seats to get best performance. As noted above, using @Kupu 's technique with the proper Duro 2-104 o-ring may be the solution to all this:

solution for D-series poppet seat DIY?

With regard to the lever, the sharper contact point where the new style lever contacted the nib at the bottom of the poppet made for slightly increased friction, although total valve opening was improved. The mechanics are suggested by the diagram below:

In any case, it is occasionally possible to "downgrade" to an older metal orifice, and lots of smooth D400 levers are around. It's worth experimenting to see if you can identify a difference in performance.

From a service standpoint with the very last D400 model, the only new challenge is getting the orifice out of the housing without damaging it, for there are no more available techno-polymer orifices on the market that I have seen.

To remove the orifice, use a small flat blade screwdriver to lever up on the two tabs in the oval holes in the side of the housing.

Then, using a straight blunt pick, carefully engage the side of the orifice from below through the stem of the housing, and carefully push up.

If the pick is engaged, the orifice will slide out. If not, it will slip and likely scratch your knife edge.

The static o-rings that seal the orifice to the housing are spec'ed by Scubapro as AS568 5-179 duro 70. However, this is roughly a 1x6mm oring, and the lands in the techno-polymer orifice measure 8.37mm diameter. A 1x6mm therefore requires significant stretch, and I am surprised at the specification. A 1mm x 7mm duro 70 fits quite well and is my choice, but as a static oring it probably makes little difference either way, as long as you can insert the orifice and it seals in the housing.

Replacing the orifice requires careful, symmetric downward pressure on the knife edge with nothing harder than your thumb. Resurfacing this knife edge will be discussed in an upcoming D-series restoration thread.

Well, that's about all I have to offer on this reg. I hope the tips above have been helpful. As always, this is just one guy's opinion, and with @Kupu 's poppet invention as an example, new ideas are always appearing for keeping this old beauty in service. I welcome any new ideas or differing opinions regarding service or performance of this regulator.