Here's what you do. You need some tools and maybe a clamp, so if you don't have that, it won't help you. But it might help others and IMO it's better than a vise for holding 1st stages.

Basically what you are going to make is a long skinny box (cage, really) out of 1X3 lumber. The interior chamber of this box needs to snugly fit the body of your MK20/25 (whichever it is, so roughly 4" long by 1.25"--take your own measurements!). Then you slip the body of the reg in this box, with the DIN fitting sticking out. Then clamp the box to a workbench, and you will be able to apply enough torque to the fitting with a 6mm allen key socket and a decent size socket wrench, without marring up the regulator as can happen in a vise. SP DIN fittings are supposed to be torqued to around 20-22 ftlbs, which is pretty tight but not like lug nuts.

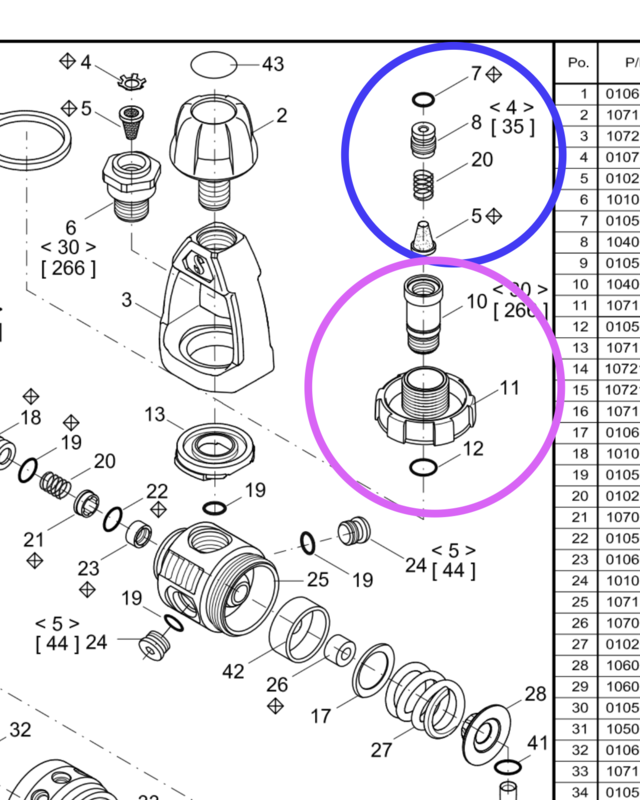

If that doesn't work, then you take every port plug out, the HP seat carrier out, and the turret off, and remove all the parts and o-rings you can, basically leaving the DIN fitting on the body. Then you put that in the freezer for several hours, then in simmering water for an hour or so, back in the freezer, back in the boiling hot water, and eventually you will be able to get that DIN retainer loose.

What sometimes happens is the threads on the DIN retainer get some salt water in them, the owner does not soak the reg well in fresh water after diving, the salt dries in the threads, and whammo it's stuck. This is where the freezing (which shrinks everything) and boiling water (which penetrates the threads) can help.