The double hook pick is one of the most useful, and yet most dangerous picks in your scuba repair inventory. It has the unique ability to reach and retrieve o-rings that lie deep in an internal groove of a regulator or hose end. This post will discuss the way to use a double hook pick without irretrievably damaging your gear.

The reason the double hook pick exists is to reach inside a regulator or hose end to snag an o-ring that a straight or curved pick simply won’t lift. Those who try to use a pick other than a double hook inevitably do one or both of the following: spear the o-ring, damaging it irretrievably, and/or scratch the groove of the equipment with the point. That’s the reason that plastic and brass picks are so popular. They are softer than the chrome plating of your equipment, and are less likely to scratch it as a result. Indeed, spearing and sacrificing an oring with a curved pick is a standard technique for many technicians. Yet it still doesn’t take much to scratch the soft brass of a regulator body with any metal pick.

Here, a ham-fisted technician chose to use a hard tool to pry out an old diaphragm, scratching the surface not once, but three times as he removed the stiff rubber part during service.

You need the right tool for the job!

An o-ring sits in a “gland” in whatever piece of equipment in which it is used. A gland is merely a groove with a smooth surface, against which the o-ring seals. It needs to be relatively smooth, so that whatever gas pressure is being sealed does not leak through the microscopic crevices created by a rough or scratched surface. At low pressures with soft o-rings (i.e., LP hoses with duro 70 o-rings), there is a lot of tolerance for abuse and corrosion, because the o-ring is often static, or not subject to much movement, in the part that gets abused.

Take a LP hose end, for example. The o-ring that seals the second stage to the hose sits in a groove (gland) in the tube beneath the sealing nut. Digging this out with a curved steel pick may deeply scar the gland, but the o-ring sits there generally unmoving, molding itself to the scarred land. The outer side of the o-ring is what seals against the regulator connection, and as long as the inside of the reg barrel isn’t scratched, your second stage may seal just fine.

But at high pressures, it’s a different matter. Scratching a similarly shaped groove inside an old Mk5 that you are trying to service will mean 3000 psi gas inevitably leaking into the ambient pressure chamber, giving you a bubbling first stage or worse. The o-ring has a harder duro (to handle the higher tank pressure) and is less able to mold itself to the scratched gland. Getting this o-ring out for replacement requires a double hook pick, and deft technique.

But a double hook pick made out of plastic or brass simply doesn’t have enough strength to last long without losing its shape and becoming useless. A steel pick will do the job, but since it is stronger than brass it will mar a brass reg. In fact, a steel pick will even scratch titanium! Using a straight or curved steel pick is a recipe for disaster, especially when a brass pick will do just as well. But when you need a double hook to reach inside a recess, the only suitable double hook pick is steel.

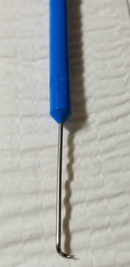

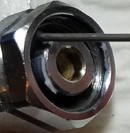

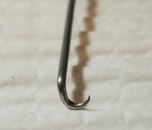

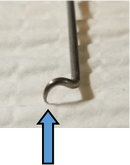

A double hook pick has a safe side:

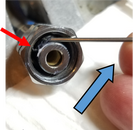

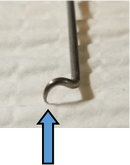

...and a dangerous side (point):

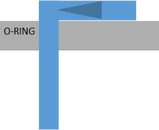

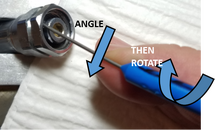

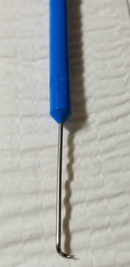

So when I buy a new double hook pick, the first thing I do is mark the handle so that I know what side is resting on the o-ring land inside my equipment. I draw a line down the handle exactly opposite the point of the hook, and hatch “the dangerous side” with a marking pen. Whenever I can see hatching, I know I mustn’t put any pressure on the groove.

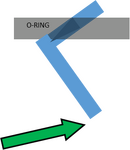

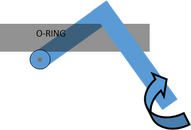

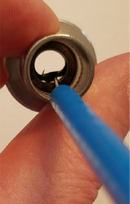

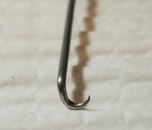

Conversely, when I roll my pick handle so the hatching is underneath, I know the smooth curved side of the hook is lowermost inside the groove.

The reason the double hook pick exists is to reach inside a regulator or hose end to snag an o-ring that a straight or curved pick simply won’t lift. Those who try to use a pick other than a double hook inevitably do one or both of the following: spear the o-ring, damaging it irretrievably, and/or scratch the groove of the equipment with the point. That’s the reason that plastic and brass picks are so popular. They are softer than the chrome plating of your equipment, and are less likely to scratch it as a result. Indeed, spearing and sacrificing an oring with a curved pick is a standard technique for many technicians. Yet it still doesn’t take much to scratch the soft brass of a regulator body with any metal pick.

Here, a ham-fisted technician chose to use a hard tool to pry out an old diaphragm, scratching the surface not once, but three times as he removed the stiff rubber part during service.

You need the right tool for the job!

An o-ring sits in a “gland” in whatever piece of equipment in which it is used. A gland is merely a groove with a smooth surface, against which the o-ring seals. It needs to be relatively smooth, so that whatever gas pressure is being sealed does not leak through the microscopic crevices created by a rough or scratched surface. At low pressures with soft o-rings (i.e., LP hoses with duro 70 o-rings), there is a lot of tolerance for abuse and corrosion, because the o-ring is often static, or not subject to much movement, in the part that gets abused.

Take a LP hose end, for example. The o-ring that seals the second stage to the hose sits in a groove (gland) in the tube beneath the sealing nut. Digging this out with a curved steel pick may deeply scar the gland, but the o-ring sits there generally unmoving, molding itself to the scarred land. The outer side of the o-ring is what seals against the regulator connection, and as long as the inside of the reg barrel isn’t scratched, your second stage may seal just fine.

But at high pressures, it’s a different matter. Scratching a similarly shaped groove inside an old Mk5 that you are trying to service will mean 3000 psi gas inevitably leaking into the ambient pressure chamber, giving you a bubbling first stage or worse. The o-ring has a harder duro (to handle the higher tank pressure) and is less able to mold itself to the scratched gland. Getting this o-ring out for replacement requires a double hook pick, and deft technique.

But a double hook pick made out of plastic or brass simply doesn’t have enough strength to last long without losing its shape and becoming useless. A steel pick will do the job, but since it is stronger than brass it will mar a brass reg. In fact, a steel pick will even scratch titanium! Using a straight or curved steel pick is a recipe for disaster, especially when a brass pick will do just as well. But when you need a double hook to reach inside a recess, the only suitable double hook pick is steel.

A double hook pick has a safe side:

...and a dangerous side (point):

So when I buy a new double hook pick, the first thing I do is mark the handle so that I know what side is resting on the o-ring land inside my equipment. I draw a line down the handle exactly opposite the point of the hook, and hatch “the dangerous side” with a marking pen. Whenever I can see hatching, I know I mustn’t put any pressure on the groove.

Conversely, when I roll my pick handle so the hatching is underneath, I know the smooth curved side of the hook is lowermost inside the groove.