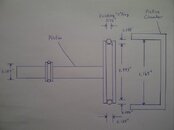

I bought this first stage a while back to use in my shop because it was cheap and had a DIN connector which were my only requirements. It was dirty and corroded looking when I got it but it cleaned up really nice. I decided to go ahead a disassemble it to see what was inside and it looks good inside also. The piston "O" ring appears to be a -120 and the stem a -007. It has four 3/8" LP ports and one 7/16" HP port. At first I didn't even care what I had, but after I cleaned it up so nice I got curious. My guess is that it is a Aqualung of some type, but would like to know for sure. I would appreciate it if some one could identify this regulator for me and confirm it has the correct "O" rings inside.

Notsure

Notsure

Last edited: