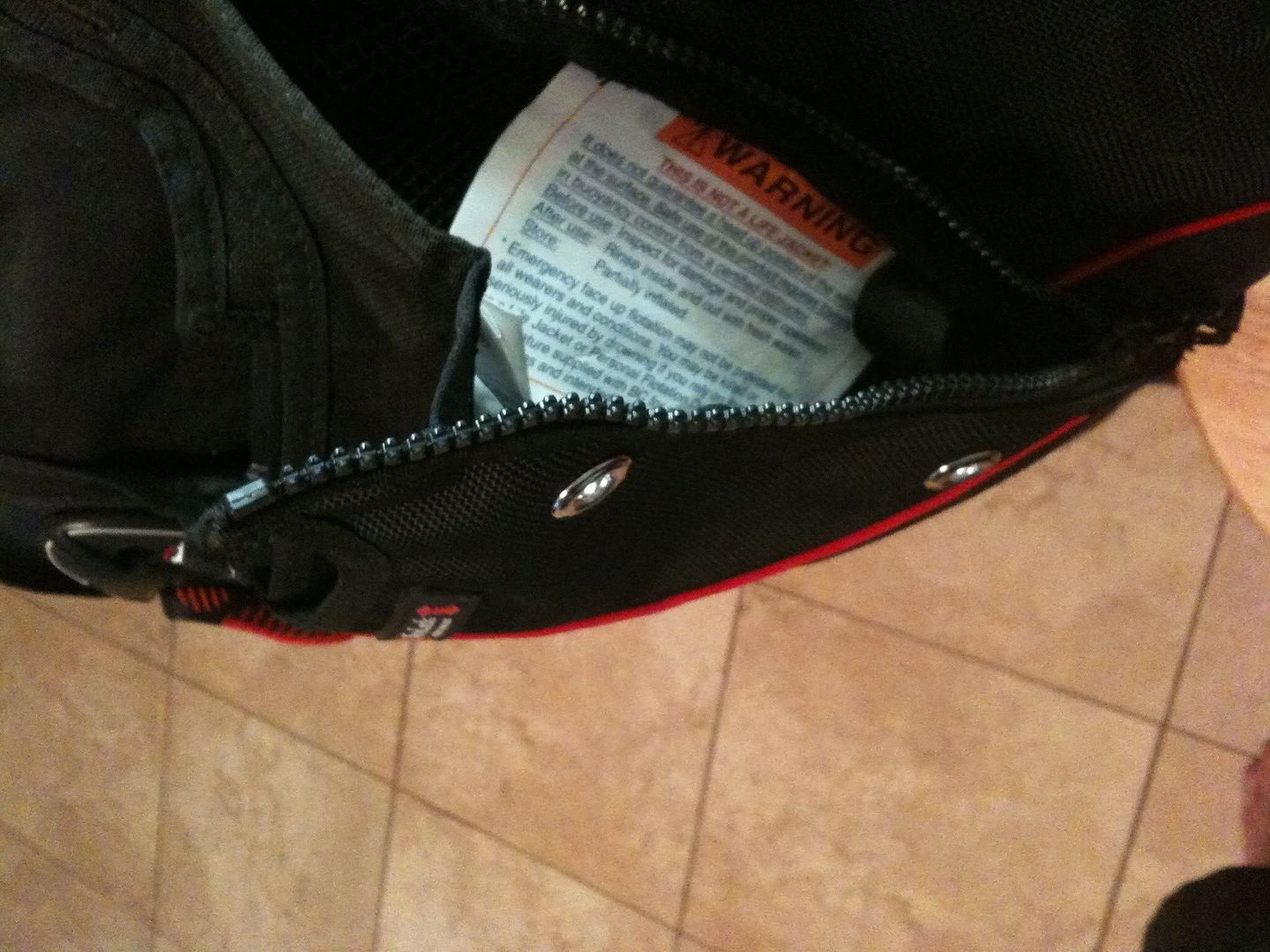

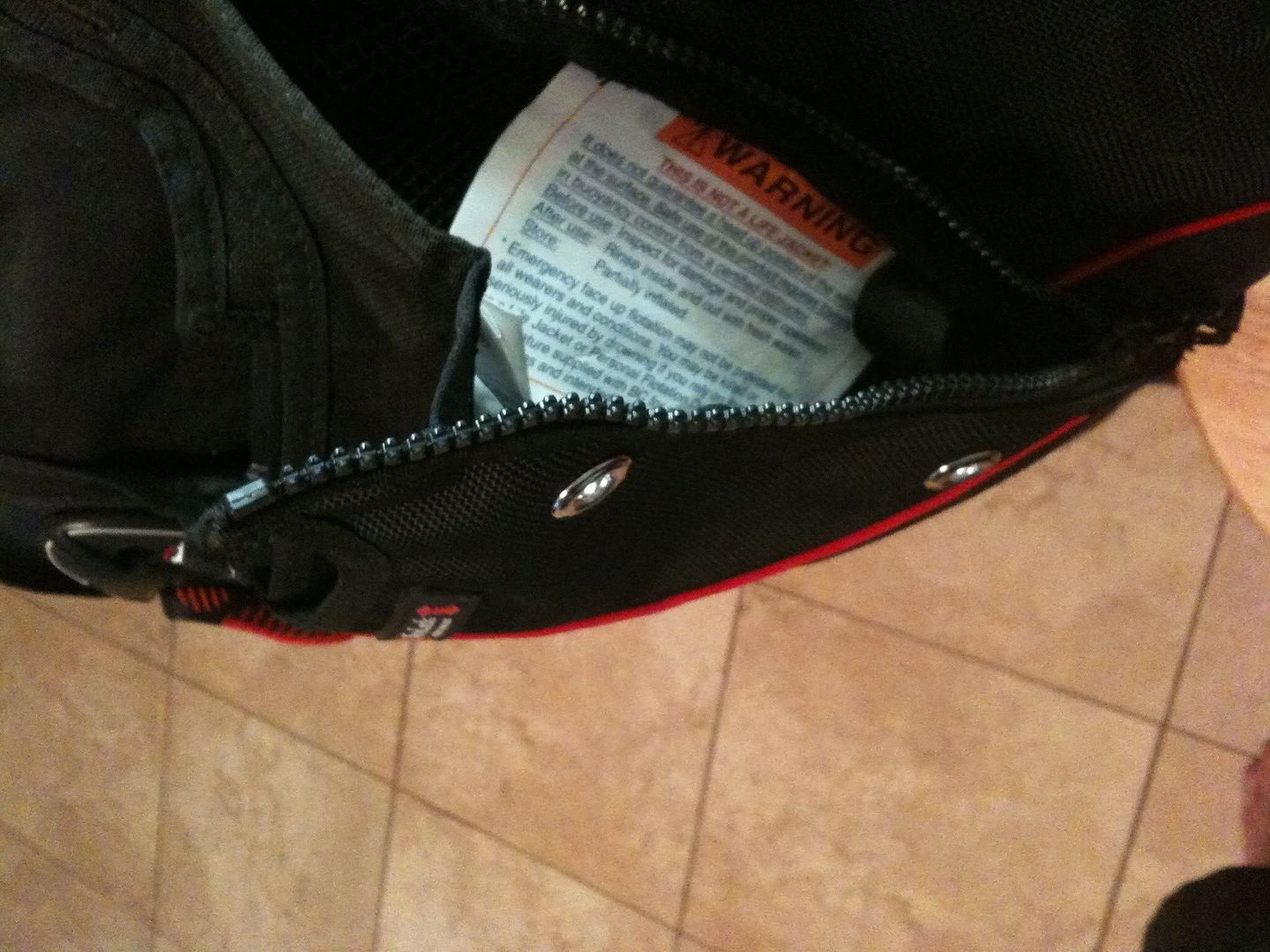

I have done exactly what you are trying to do. I would not use the methods described nor the chintzy cheap grommets in the picture.

I recommend finding the best grommets (another name to search under eyelets) the size you want. I found some in Germany in the Home Depot type store but they can be found elsewhere and on line. The best is stainless, but they require a special press. The next best is aluminum, then zinc plated brass. A good source for almost anything is McMaster Kerr. They are not the cheapest, but they have most anything.

You'll also need a hole punch. It is a solid rod with a hollow end. The hollow end is sharp. You can get a set of these at Harbor Freight or similar for really cheap. You can make one that will suffice a few uses by buying some kind of tube the right diameter and sharpen one end.

Mark where you want you hole with a silver sharpie. Make triple sure it is exactly where you want it because you cannot undo anything from here on.

Put a piece of wood inside the pocket to absorb the blow of the punch. Make sure nothing is under it that can get damaged. I use a 4x4 fence post for an anvil. Punch your hole by making one good hit on the end of your punch with a hammer. If everything went right, you will have a clean cut that is exactly the right size. (I recommend practice before punching up your BCD.)

Have fun.

Next singe the hole. I like a good torch lighter. The fibers around the hole will fuse nicely since they are most certainly nylon. It should only take a couple of seconds exposure to the heat.

Now you can put in your grommet or eyelet. A grommet has two pieces; one swages into the other. An eyelet is one piece where one side is formed/flared to crimp. Make sure it clinches all around. You can test by trying to turn the eyelet with respect to the fabric. It should not turn. It should be crimped firmly into the cloth.

Lastly install your knife.

An alternative is to grip your hole punch with vice grips. Heat the cutting end with a torch and press it into the fabric. Of course it should be supported underneath, since you can easily punch a hole through all layers of the BCD with the hot punch. This will actually save the separate step of singeing but I like the open flame fusing.

Another option is find a parachute repair shop, a sail maker, or an awning or boat cover maker in your area and sweet talk them into helping you. They may even have the eyelet you need in stock in stainless and the special press to install them.

Yet ANOTHER option. Look for a paper drill….not a paper punch, but a paper drill. That will make a nice hole.